Pressure yielding mechanism

A technology of sheet pressing and rod body, which is used in mining equipment, earth-moving drilling, bolt installation, etc., can solve the problems of low elongation rate of ordinary bolts, support resistance cannot be adjusted with the deformation of bolts, and can not meet the needs of large deformation. , to achieve the effect of good support and pressure, good effect and flexible change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

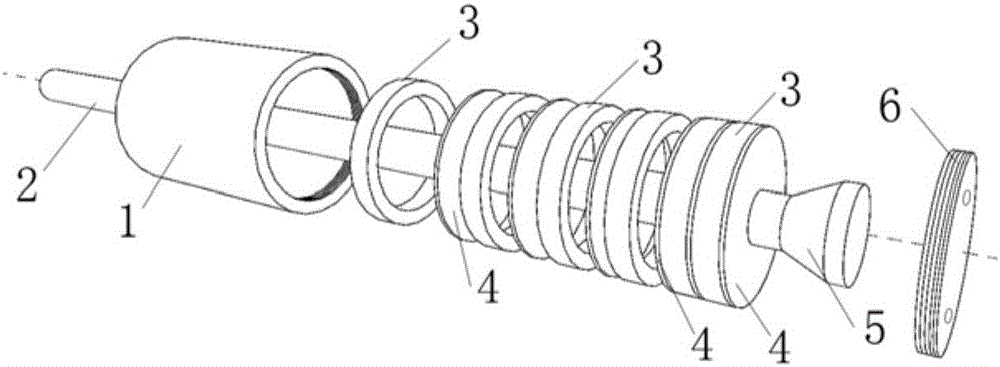

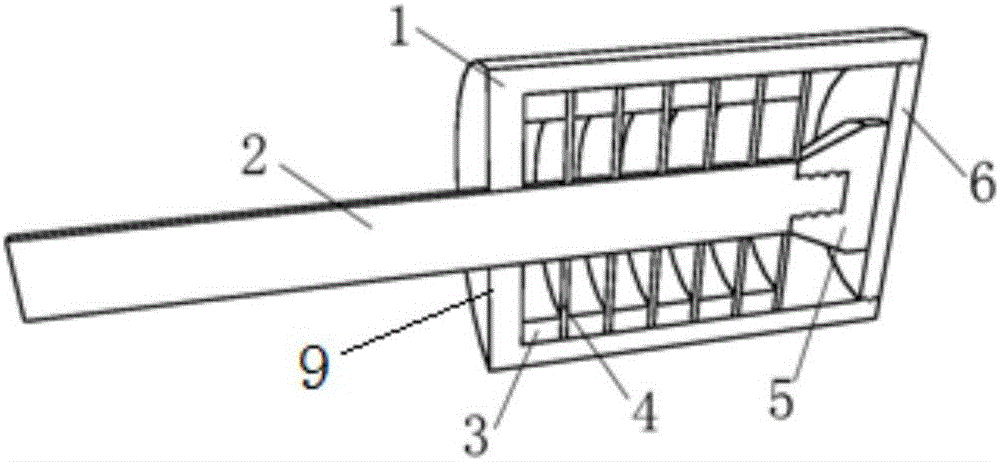

[0033] Such as figure 1 The pressure relief mechanism shown is composed of a shell 1, a rod body 2, an annular gasket 3, a pressure relief sheet 4, a cutting head 5, and a sealing cover 6.

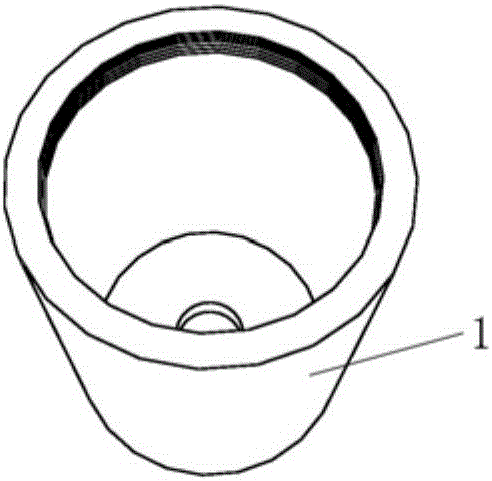

[0034] The shell 1 is a metal cylinder with a bottom plate of a certain thickness and strength, and its upper part is provided with threads, which can be closed with a sealing cover 6 . There is a circular hole in the center of the cylinder bottom plate, and the diameter of the hole is slightly larger than the diameter of the rod body 2, so that the rod body 2 can slide up and down in the circular hole. The shell 1 has sufficient strength to ensure that the deformation of the anchor rod is negligible during the stress process.

[0035] The rod body 2 is a common anchor rod in engineering, such as threaded steel, round steel, etc., and the selection of its diameter and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com