Abradable bucket shroud

A technology of moving blades and shrouds, which is applied in the direction of engine components, machines/engines, blade support components, etc., and can solve problems such as efficiency loss, reduced component life, and abrasion of the tip of the moving blade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

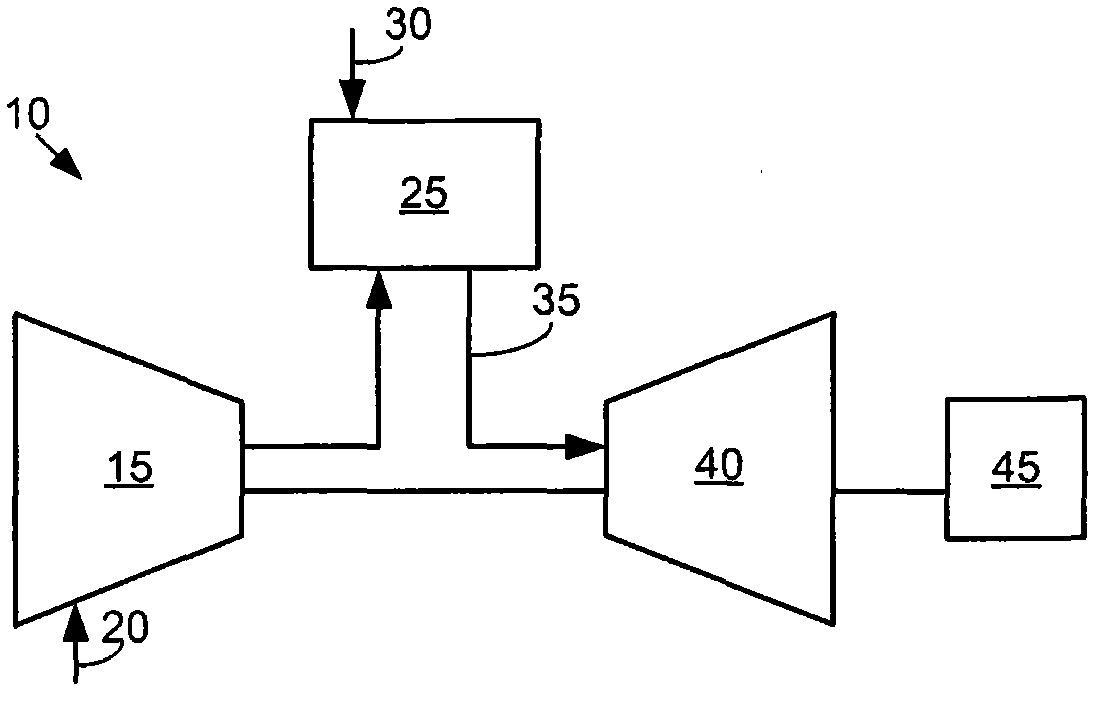

[0056] Referring now to the drawings, in which like numerals refer to like elements throughout the several views, figure 1 A schematic diagram of gas turbine engine 10 as may be described herein is shown. Gas turbine engine 10 may include a compressor 15 . Compressor 15 compresses incoming air flow 20 . Compressor 15 delivers compressed air flow 20 to combustor 25 . Combustor 25 mixes compressed air stream 20 with compressed fuel stream 30 and ignites the mixture to generate combustion gas stream 35 . Although only a single combustor 25 is shown, the gas turbine engine 10 may include any number of combustors 25 . The combustion gas stream 35 is in turn delivered to a turbine 40 . Combustion gas flow 35 drives turbine 40 to produce mechanical work. The mechanical work produced in turbine 40 drives compressor 15 and an external load 45 such as a generator.

[0057] Gas turbine generator 10 may utilize natural gas, various types of syngas, and / or other types of fuels. Gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com