Device for testing partitioned pad guide bearing of through-flow set

A bearing test and block technology, applied in the direction of mechanical bearing testing, etc., can solve the difficulty of manufacturing, installation, adjustment, and maintenance, and it is difficult to achieve large size of cylindrical bush guide bearings, and it is difficult to meet the development needs of large-scale tubular units. and other problems to achieve the effect of verifying performance and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

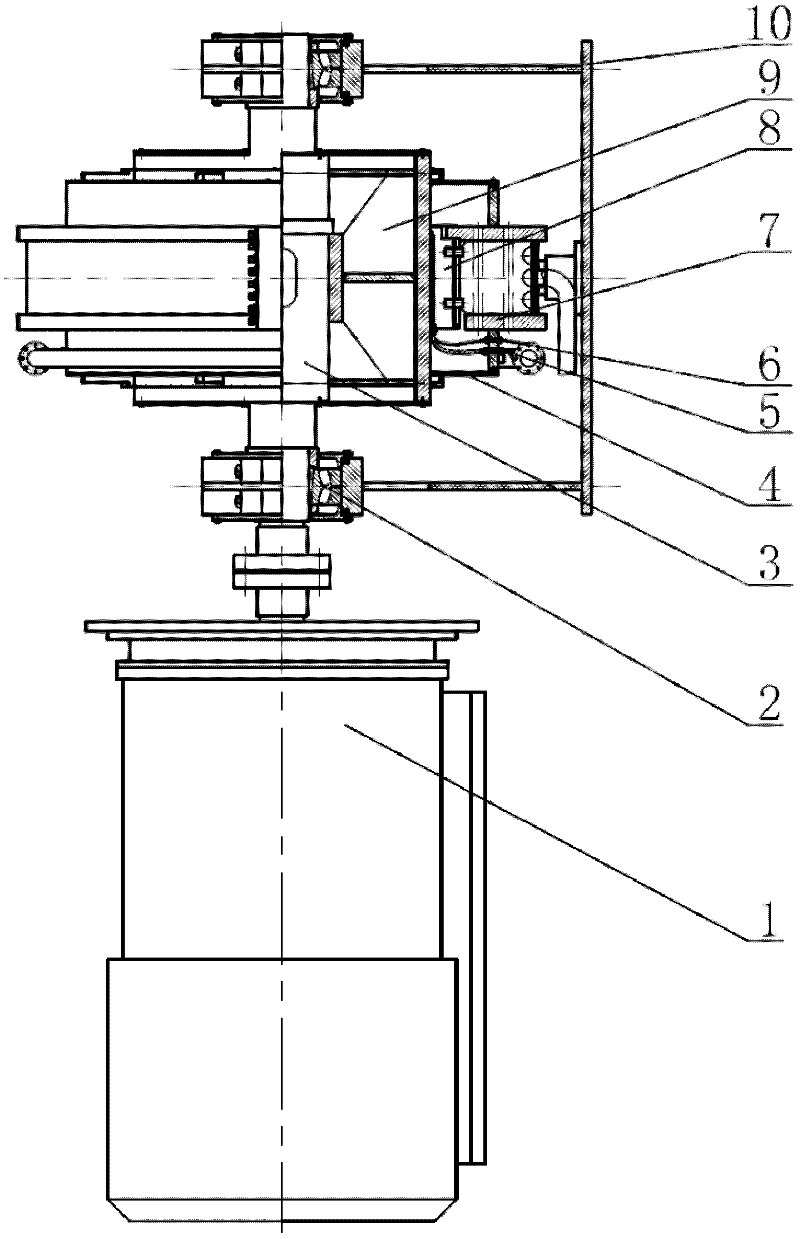

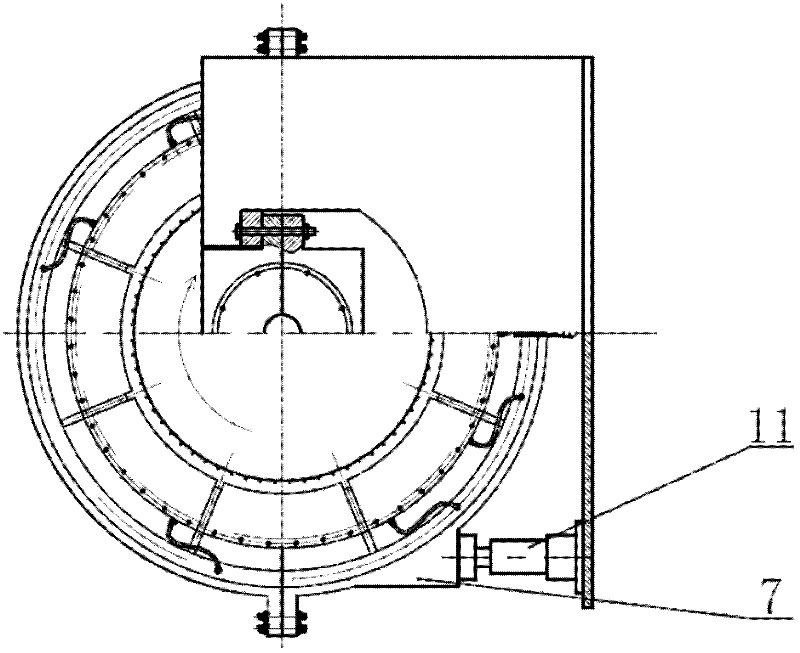

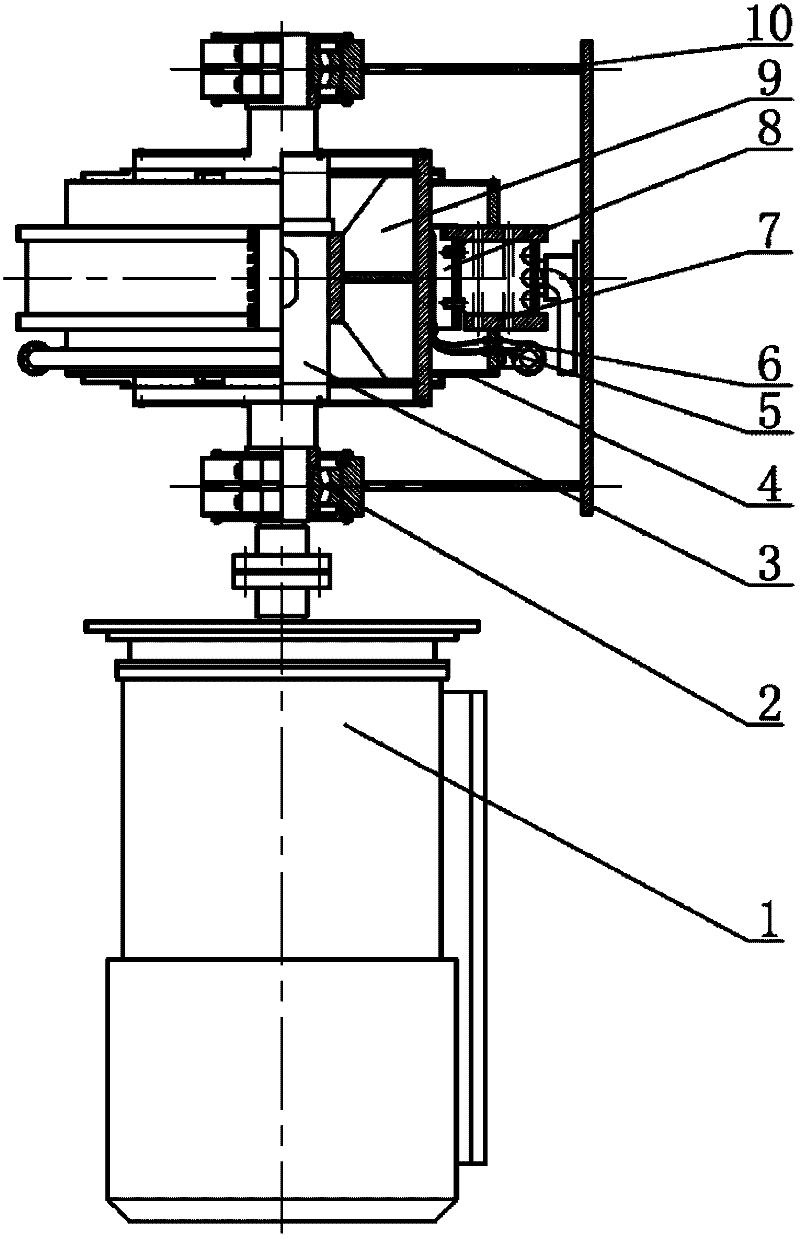

[0008] Such as figure 1 The block tile guide bearing test device of the tubular unit shown in the figure is composed of the following components: motor 1, rolling bearing 2, main shaft 3, oil retainer 4, lubricating pipeline 5, high-pressure oil jacking pipeline 6, test bearing bracket 7. Block tile test bearing 8, sliding rotor 9, fixed bracket 10, electric synchronous hydraulic jack 11, motor 1 is connected to main shaft 3 through a coupling, and main shaft 3 is connected to sliding rotor 9 through a key, so that the torque of the motor is directly transmitted On the sliding rotor, the main shaft 3 is supported by the rolling bearing 2, and the rolling bearing 2 is installed on the fixed bracket 10, and the sub-tile test bearing 8 is installed in the inside of the test bearing bracket 7 through the pillar pin, such as figure 2 As shown, the test bearing bracket 7 is set in the sliding rotor 9 and coaxial with the main shaft 3, and the electric synchronous hydraulic jack 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com