Simulated water pressure loading device and method used for tunnel structure test

A technology for simulating water pressure and loading devices, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as low precision, inability to accurately apply full-circle loads, and large volume, so as to ensure construction and operation safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

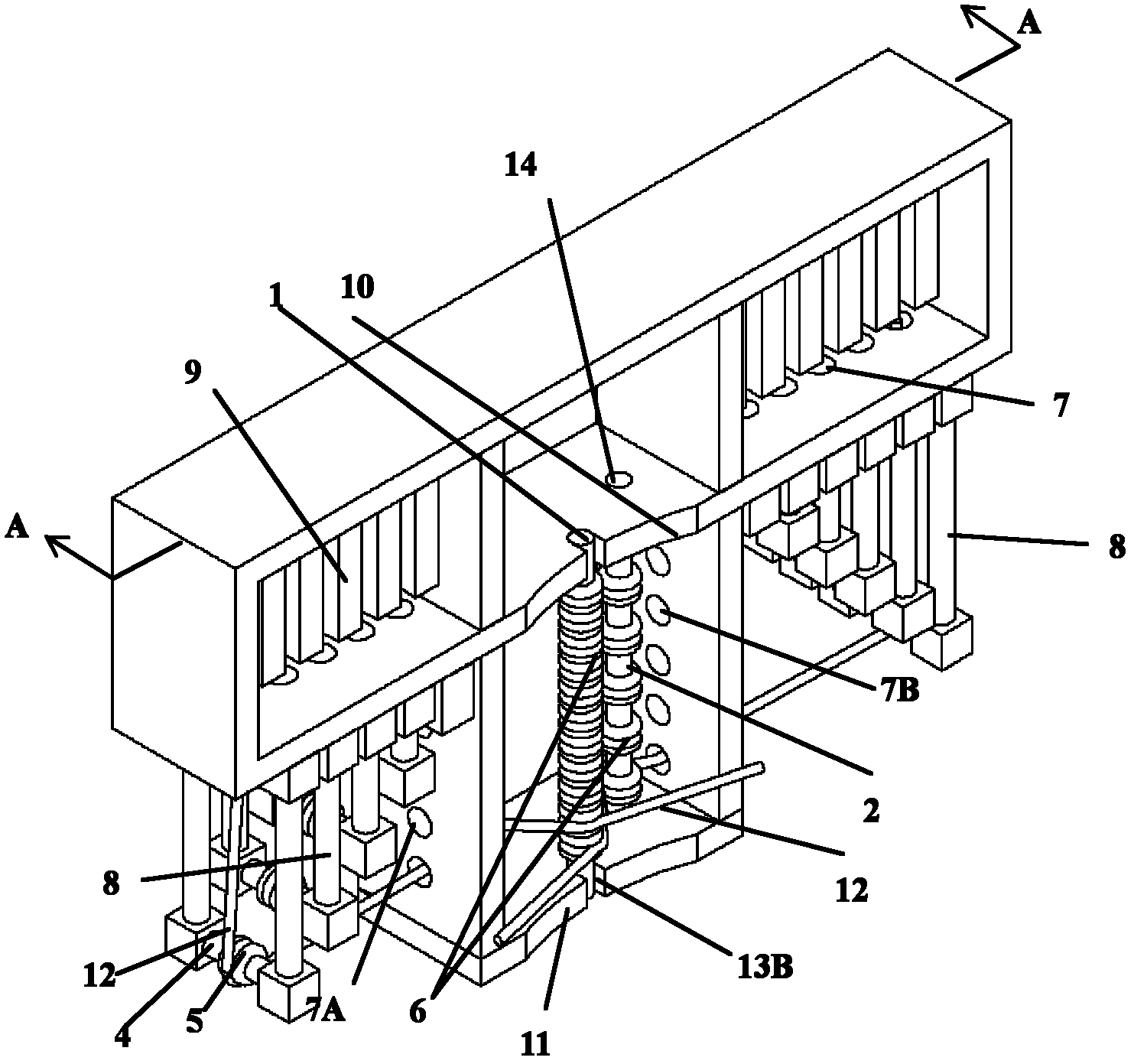

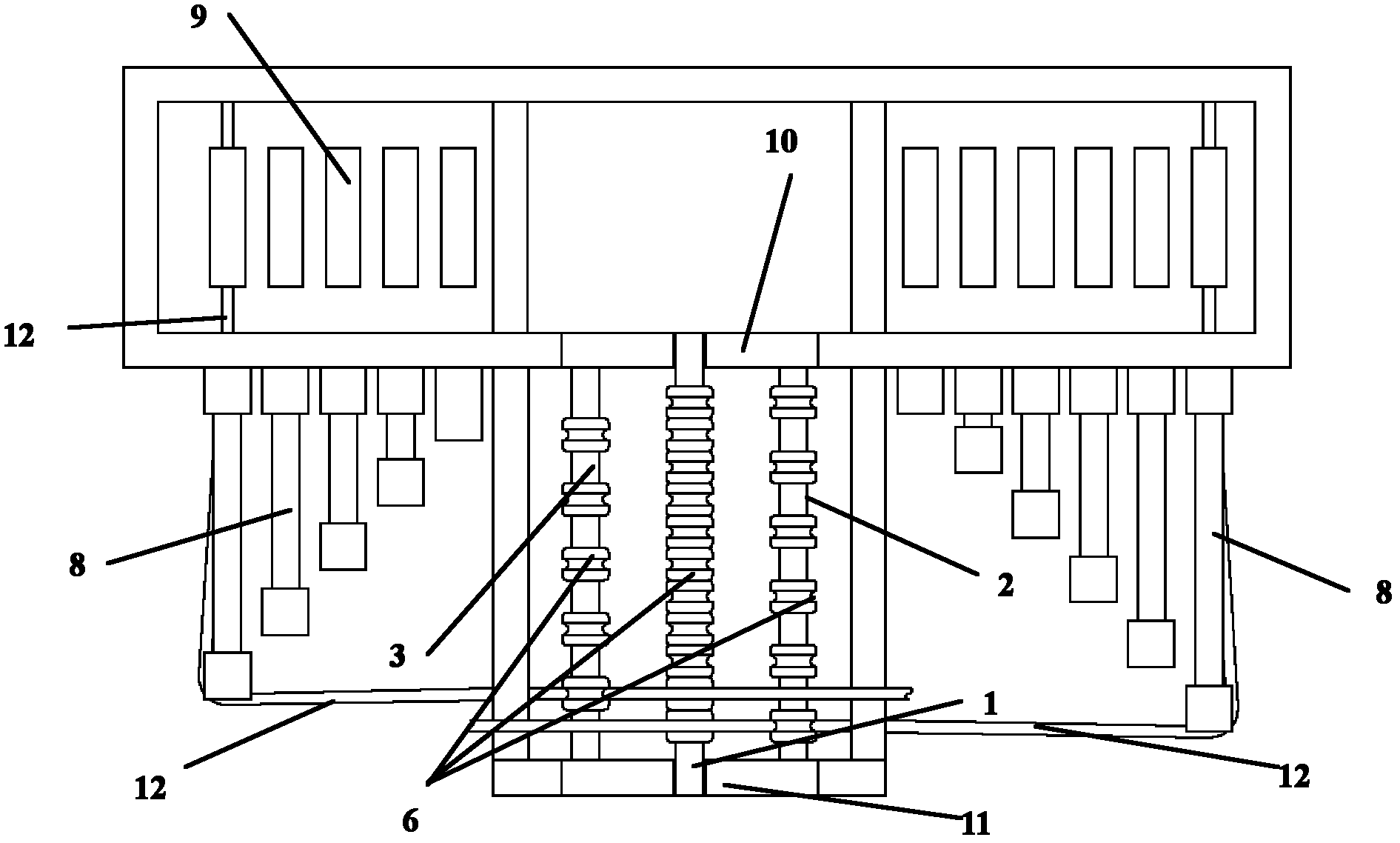

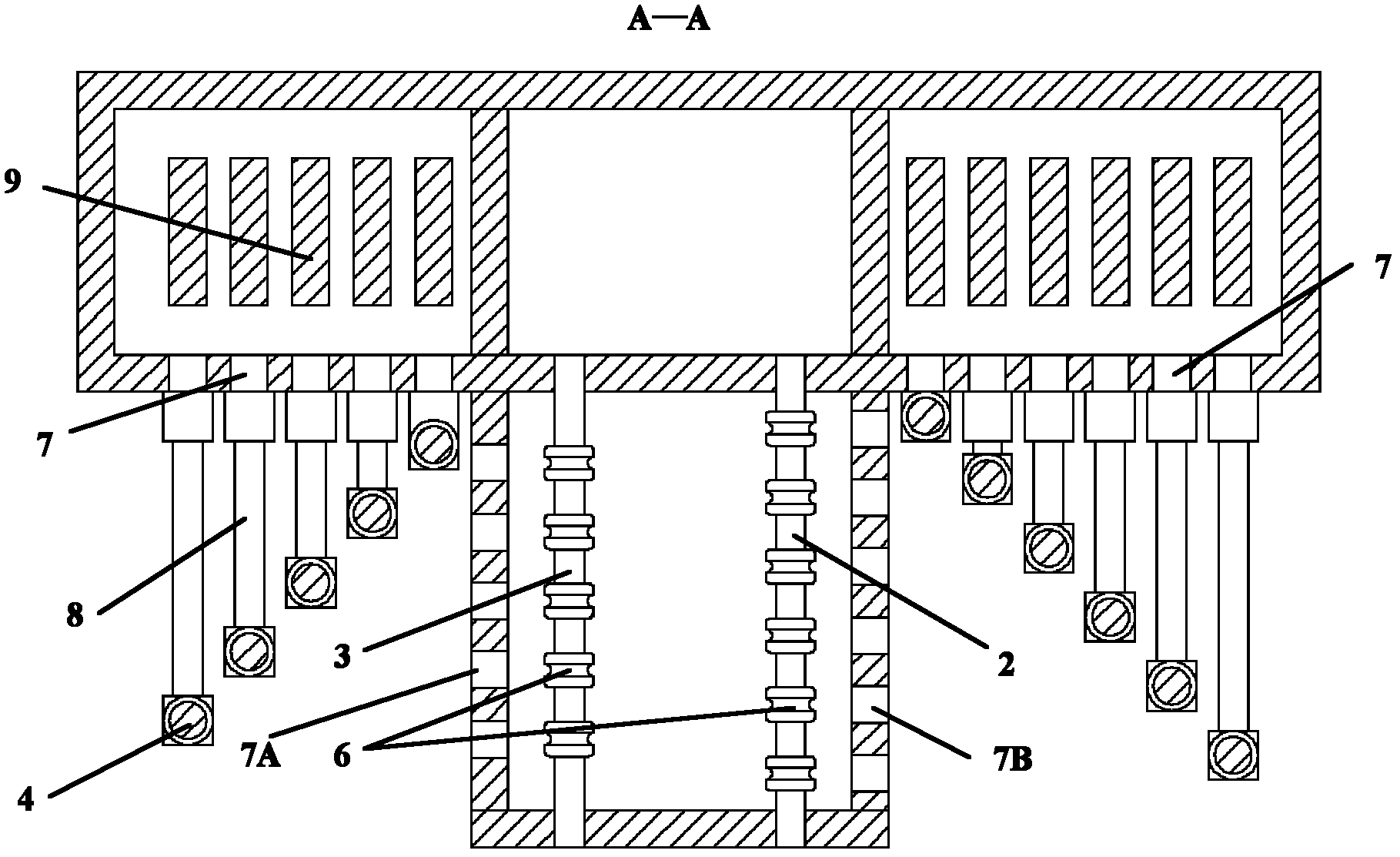

[0035] Figure 1-5 Shown, a kind of embodiment of the present invention is: a kind of simulated hydraulic pressure loading device for tunnel structure test, it is characterized in that:

[0036] The overall structure is arranged in a T shape, the upper part is the left, middle and right frames, and the lower part is the lower frame; the force sensor 9 is arranged in the space of the left and right frames, and a fine-tuning screw is arranged above the force sensor 9; the middle frame One side of the wing plate is provided with a wing plate groove 10;

[0037] Positioning holes 7 are arranged on the wing plates of the left and right frames, and the positioning holes 7 on the wing plates of the left and right frames correspond to the front and rear paired cantilever columns 8, and each pair of cantilever columns 8 below the left and right frames It is in the shape of "eight" in the horizontal direction; each pair of cantilever columns 8 is provided with a horizontal shaft 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com