Modular plug

A crystal head and main body technology, applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problem of damage to the wire crimping part of the crystal head, and achieve the effect of reducing the damage caused by the wire crimping part and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

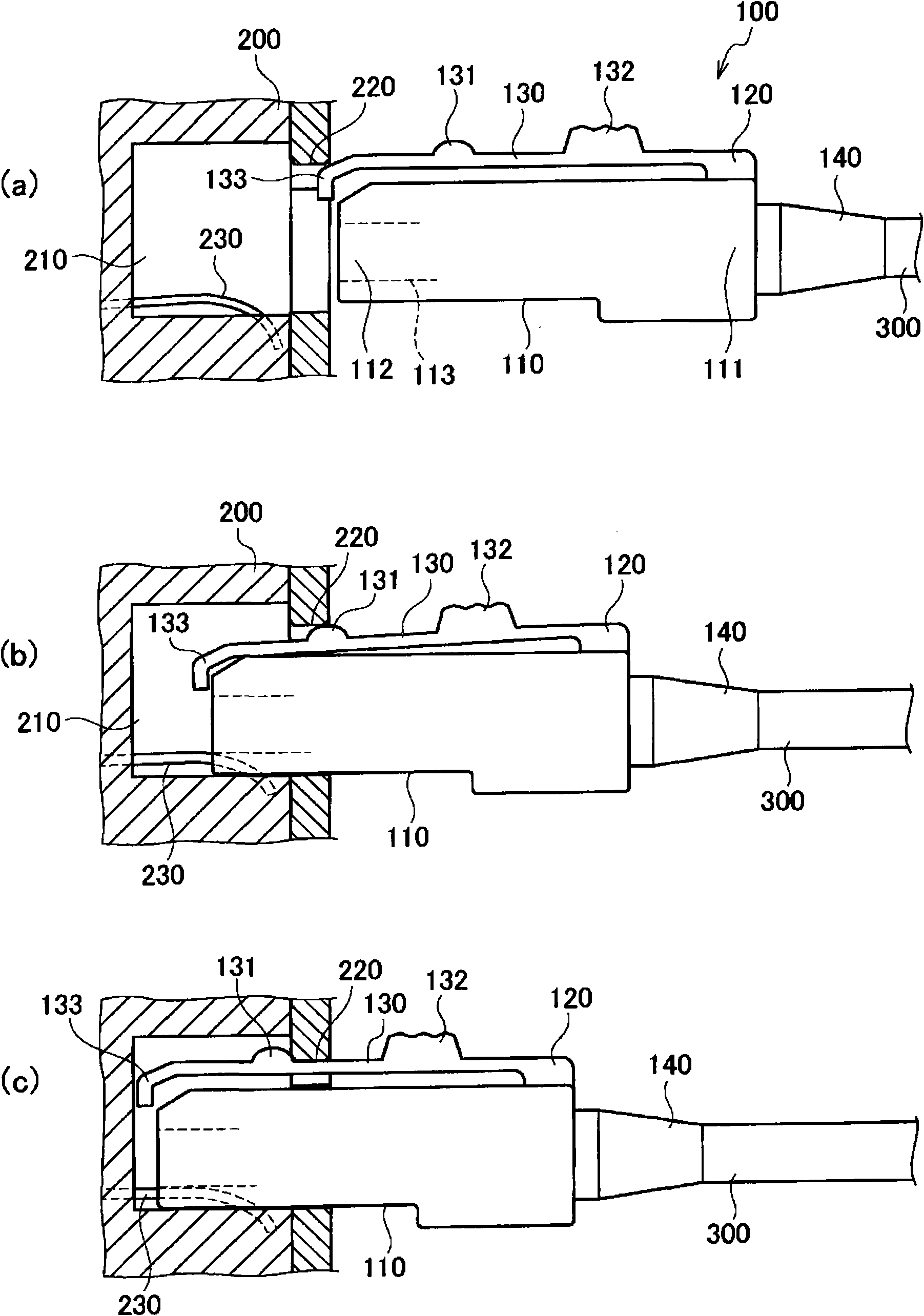

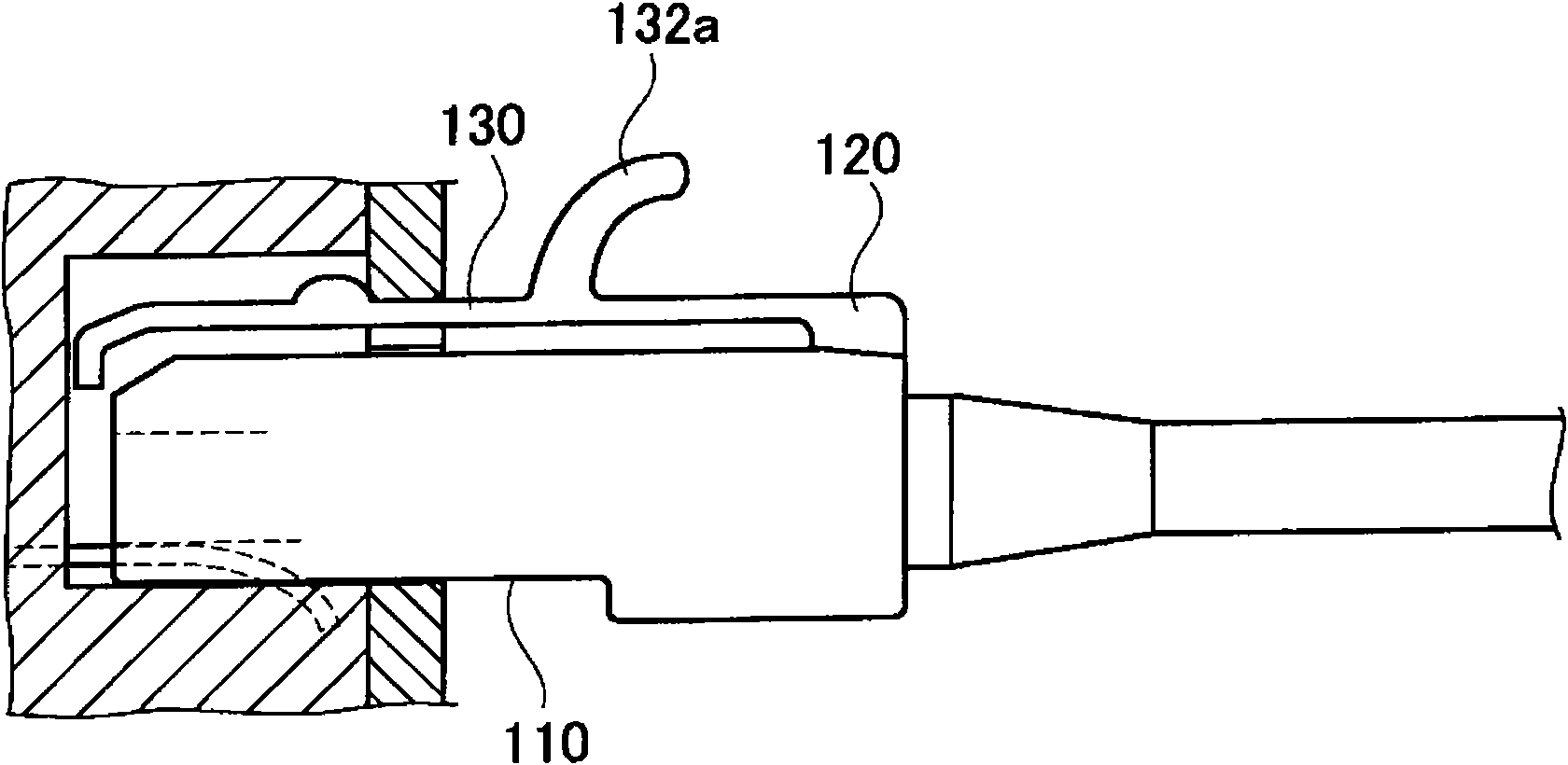

[0027] Embodiments of the present invention will be described with reference to the drawings. In the drawings of the following embodiments, the same or similar reference numerals are given to the same or similar parts.

[0028] (1) The overall structure of the modular connector

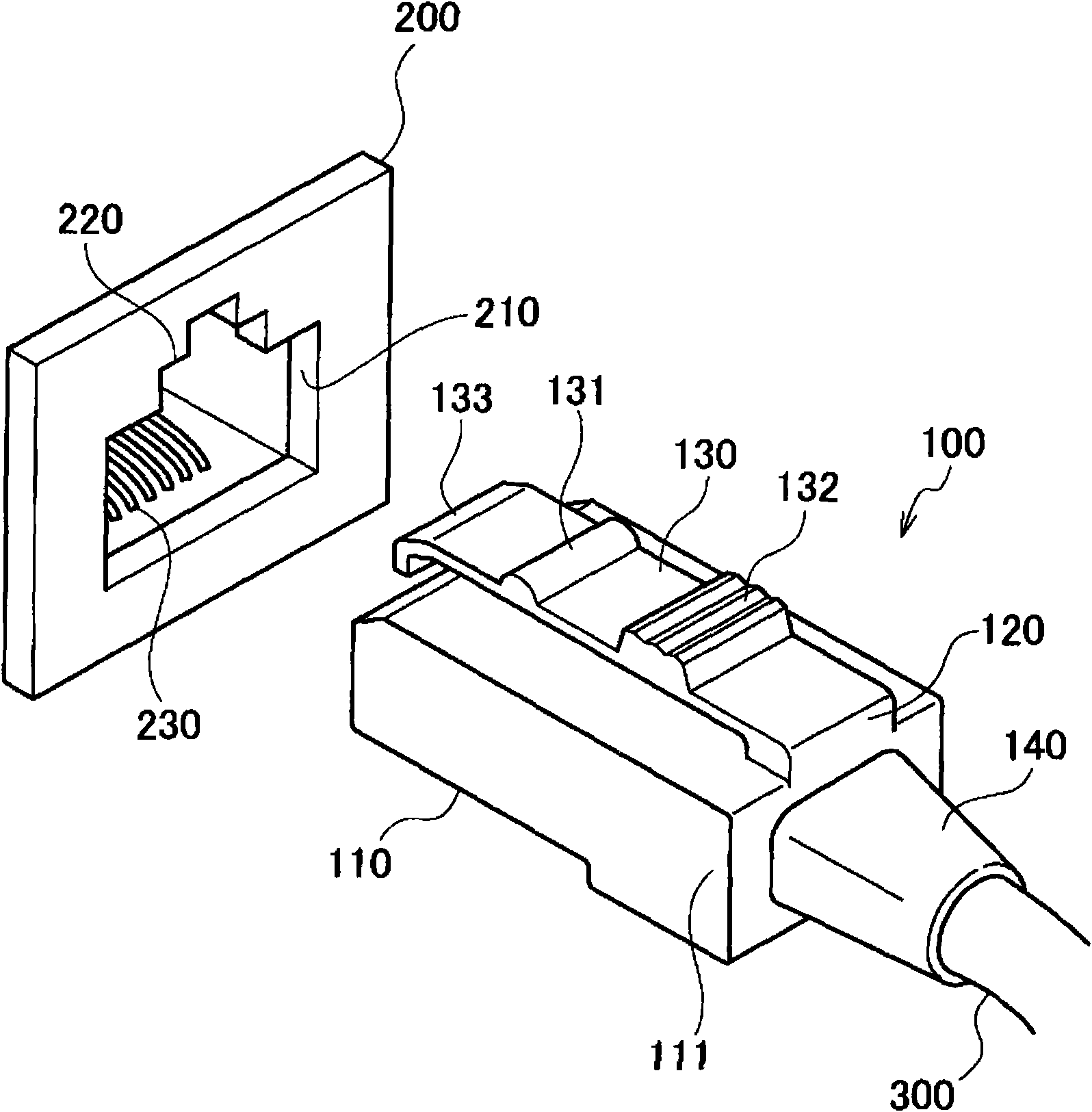

[0029] figure 1 It is a perspective view showing the overall structure of the modular connector of this embodiment.

[0030] Such as figure 1 As shown, the modular connector of this embodiment is composed of a modular socket 200 and a plug 100 inserted into the modular socket 200 .

[0031] The modular jack 200 is installed on devices such as telephones and LAN devices. The modular socket 200 has an opening 210 into which the plug 100 is inserted. At the bottom of the opening 210, a terminal 113 connected to the crystal head 100 (refer to figure 2 (a)) The terminals 230 are electrically connected. A notch 220 is provided at an upper portion of the opening portion 210 . In addition, in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com