Preparation method of running sports clothes and running sports clothes

A sportswear and sports technology, applied in clothing, clothing, protective clothing, etc., can solve problems such as unreasonable design of running sportswear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

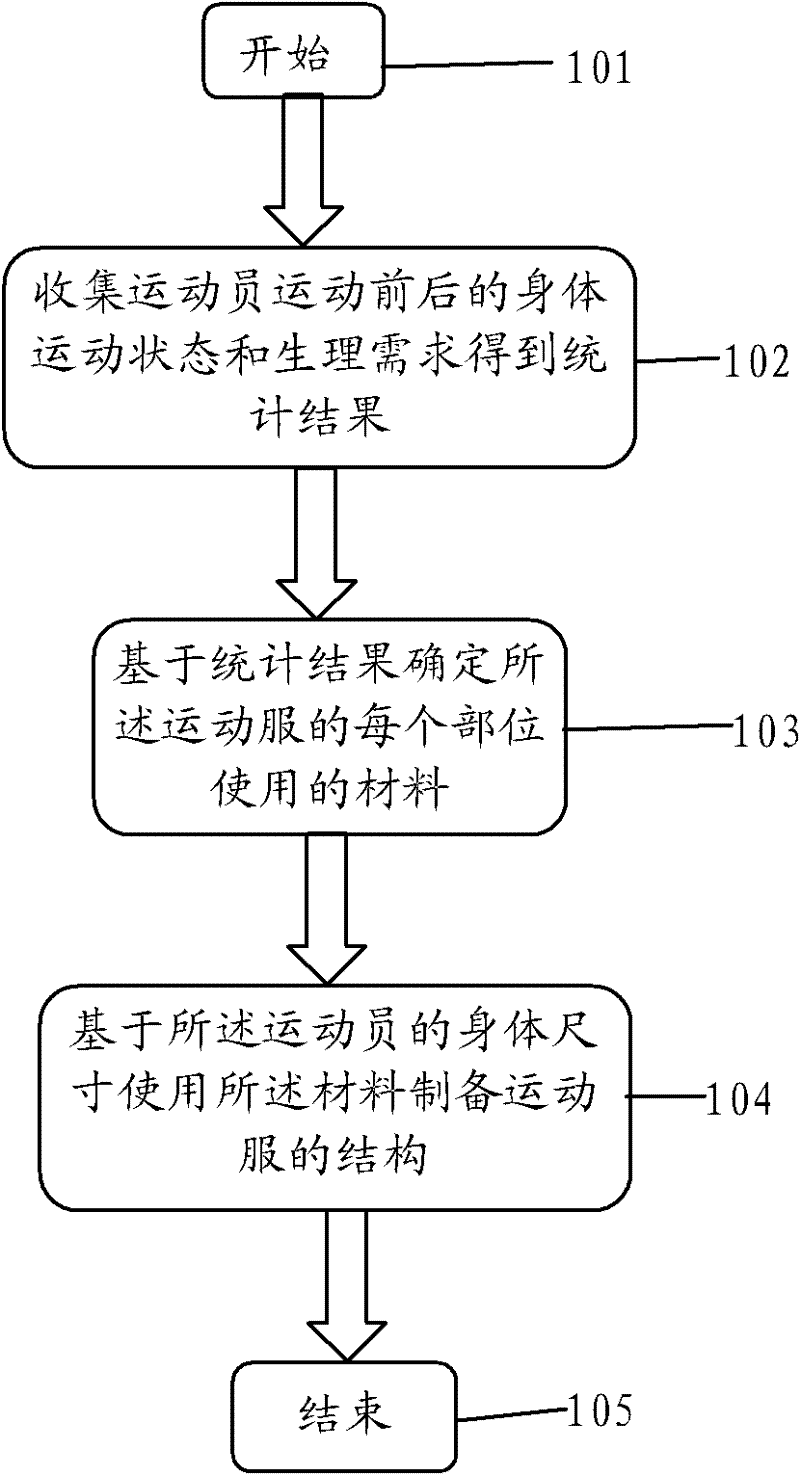

[0051] like figure 1 Shown is the flow chart of the first preferred embodiment of the preparation method of running sportswear of the present invention, and described method step starts at step 101; Then proceeds to step 102, collects the physical activity state and physiological demand of the athlete before and after exercise to obtain statistical results Proceed to step 103 after step 102 ends, determine the material used in each position of the sportswear based on statistical results; proceed to step 104 after step 103 ends, use the material to prepare running sportswear based on the body size of the athlete ; The method ends at step 105 .

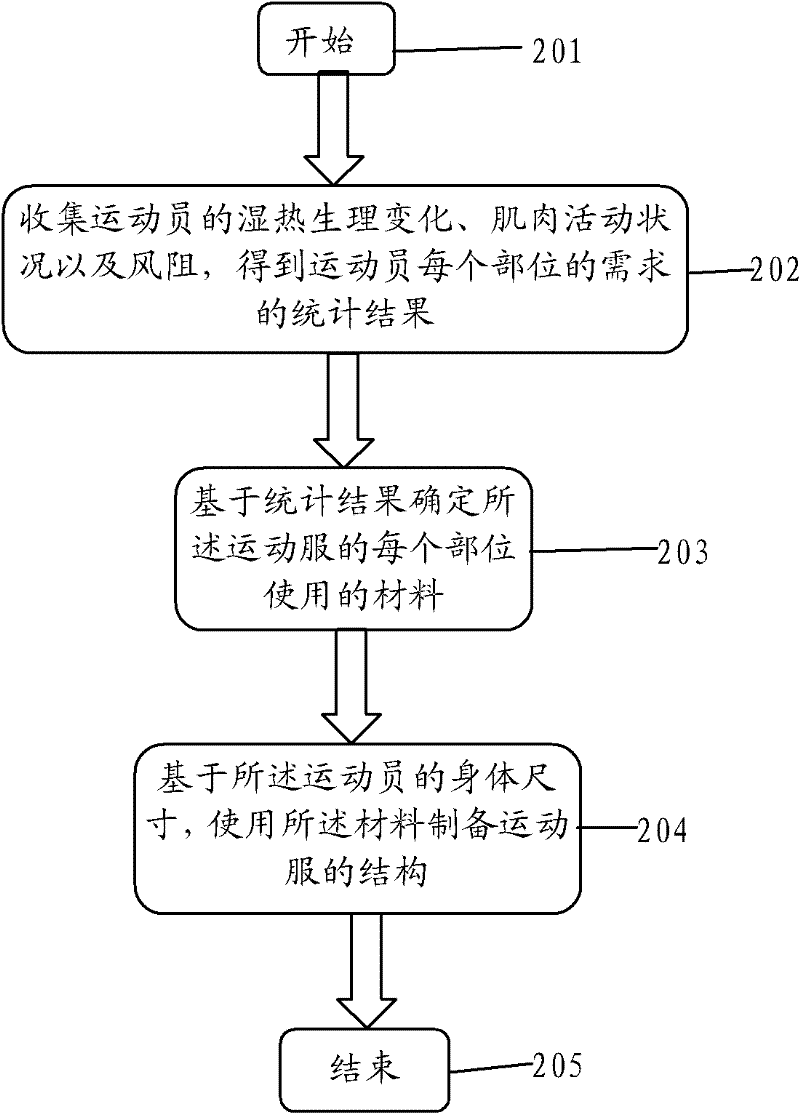

[0052] like figure 2 Shown is the flow chart of the second preferred embodiment of the preparation method of running sportswear of the present invention, and described method step starts at step 201; Then proceeds to step 202, collects the athlete's damp heat physiological change, muscle activity condition, wind resistance, feel And ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com