Liquid and solid fluidized bed sorting machine for three products and working method thereof

A fluidized bed and three-product technology, applied in the field of sorting machines, can solve the problems of reduced sorting capacity and low concentration, and achieve the effects of enhanced control capacity, improved sorting accuracy, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

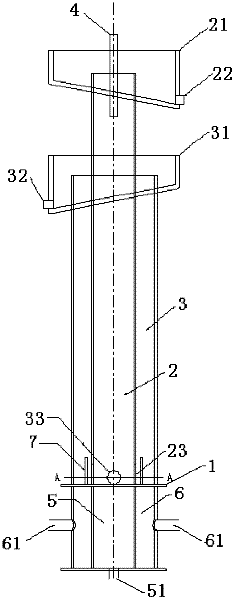

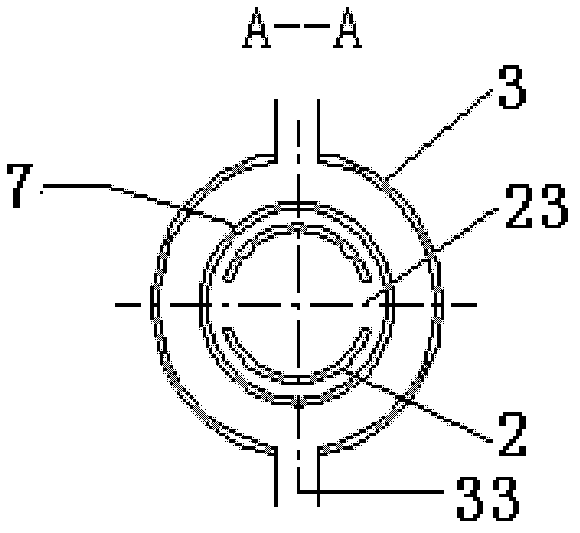

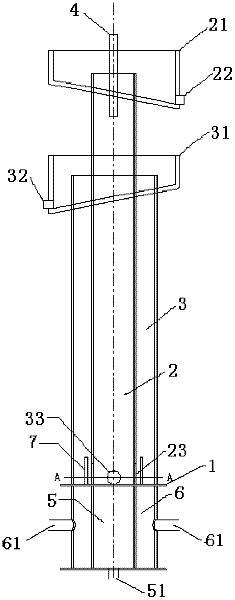

[0017] Such as figure 1 As shown, the device of the present invention includes a top water distribution plate 1 with a through hole, and an inner sorting chamber 2 and an outer sorting chamber 3 are concentrically arranged on the top water distribution plate 1 . Wherein, the inner sorting chamber 2 is used as the first stage sorting chamber, which is higher than the outer sorting chamber 3, and a feeding pipe 4 is arranged in the upper opening. The first section overflow tank 21 is arranged outside the opening of the upper part of the inner sorting chamber 2, and the first section overflow port 22 is arranged at the bottom of the first section overflow tank 21 as the first overflow outlet; the lower part of the inner sorting room 2, Near the top water distribution plate 1, several discharge ports 23 are arranged symmetrically as the first section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com