Centrifugal clutch

A centrifugal clutch and counterweight technology, applied in the field of clutches, can solve the problems of short service life, increase production cost, low strength, etc., and achieve the effects of reducing frictional heat and chatter, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0072] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of two preferred embodiments with reference to the drawings.

[0073] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

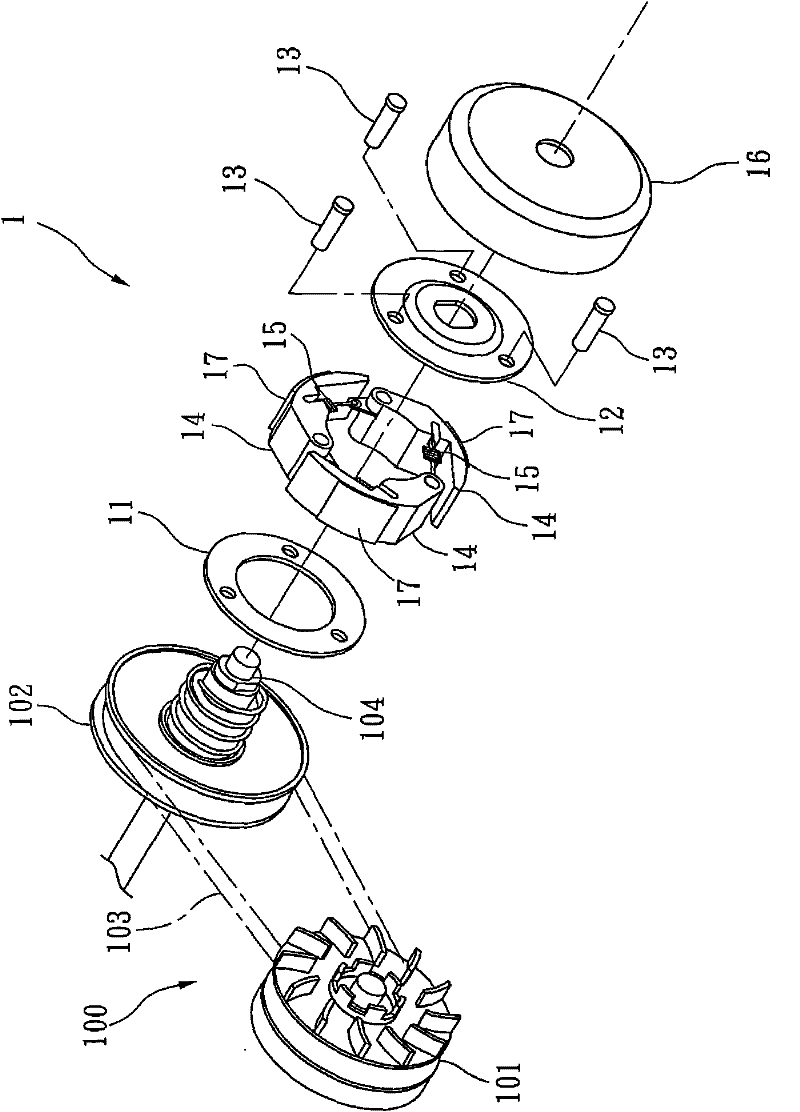

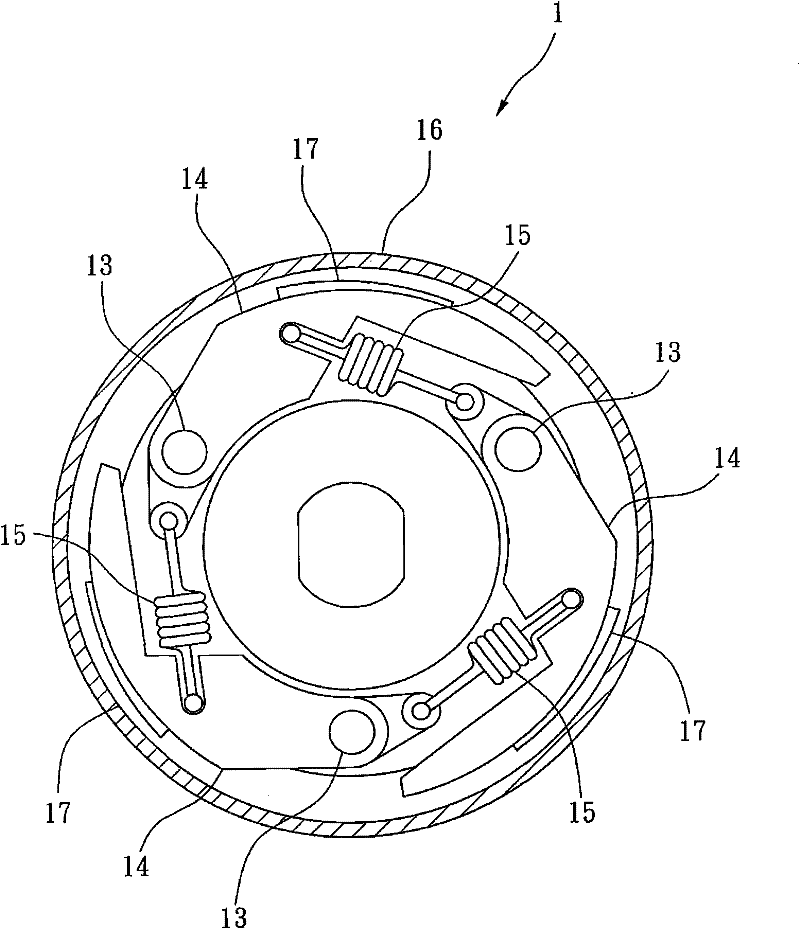

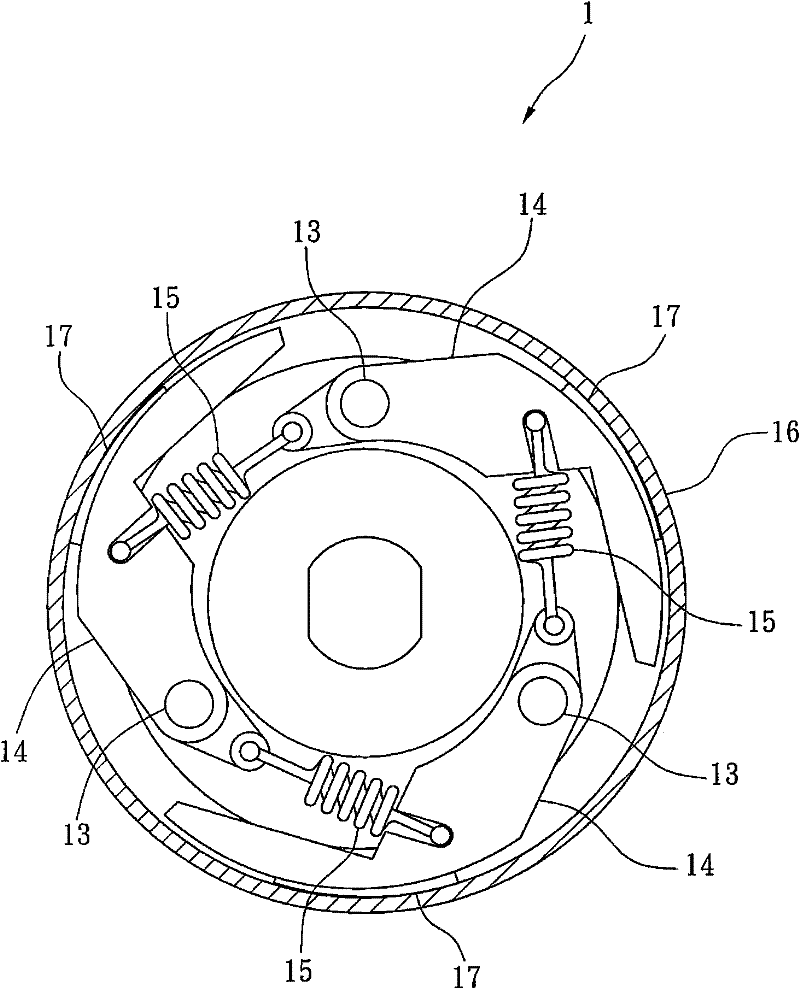

[0074] refer to Figure 4 The first preferred embodiment of the centrifugal clutch 2 of the present invention includes a drive unit 3 , a friction unit 4 located in the drive unit 3 , and an auxiliary unit 5 that assists in driving the friction unit 4 .

[0075] The drive unit 3 includes a base plate 31 and a drive plate 32 arranged at intervals, wherein the base plate 31 is formed with a plurality of positioning holes 311, and the drive plate 32 has a mounting portion 321, a mounting portion 321 The flange portion 322 extending radially outward from the bottom edge, a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com