X-ray tube with improved vacuum processing

一种X射线管、X射线的技术,应用在X射线管的处理领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

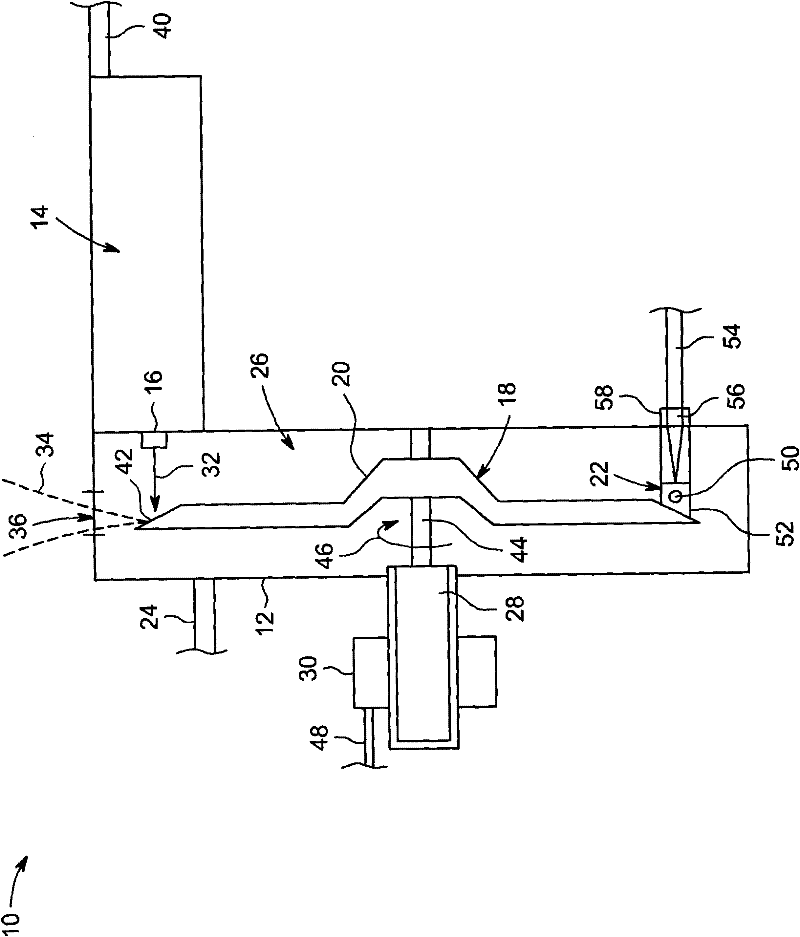

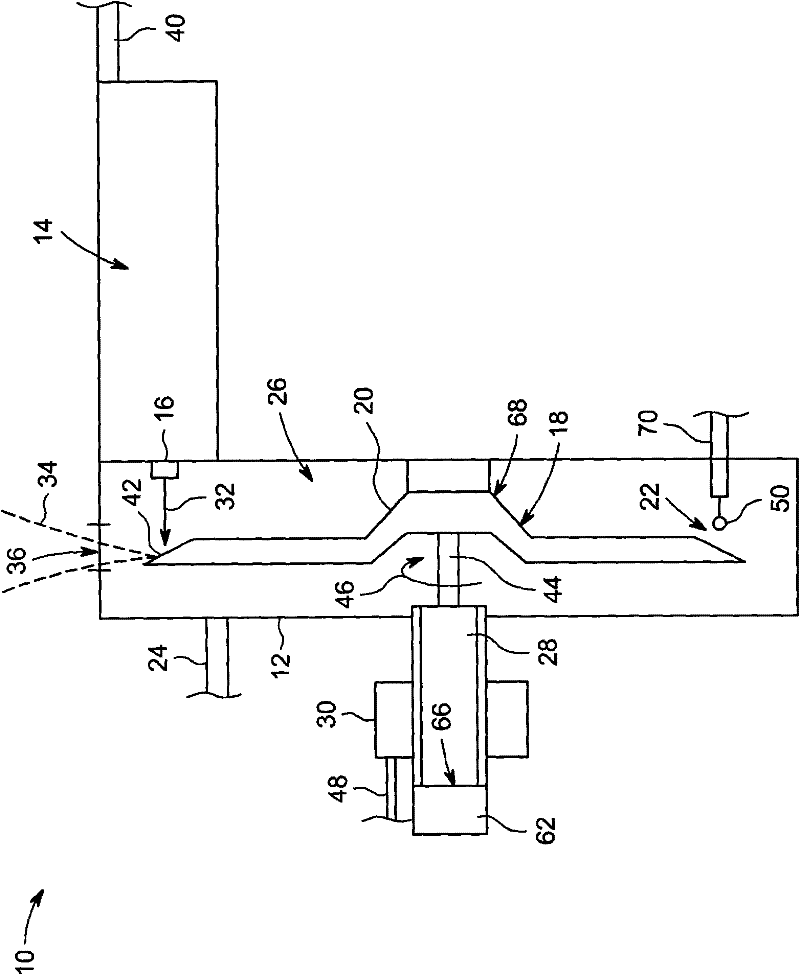

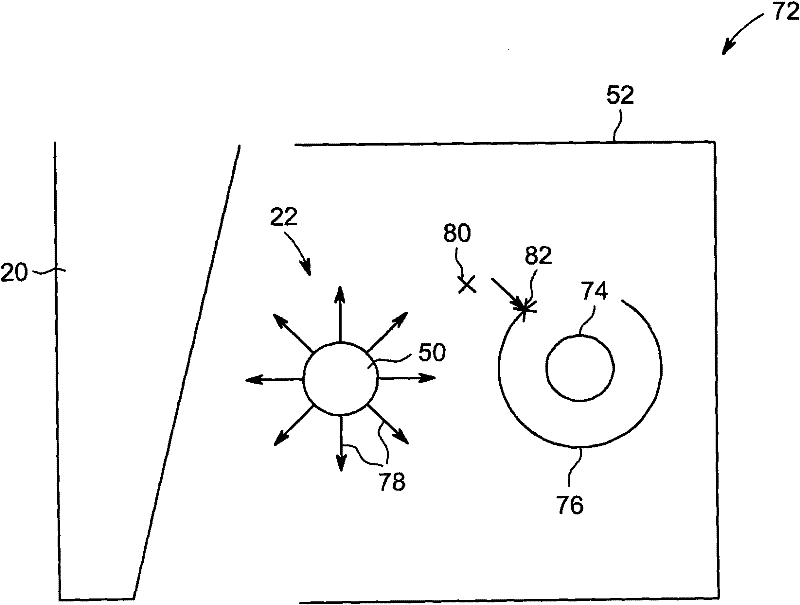

[0014] This approach is directed to the integration of the sub-cathode within the X-ray tube. This sub-cathode can be employed in processing X-ray tubes. More specifically, during X-ray tube processing, the sub-cathode employed in this approach may be heated by an electrical current, which causes electrons to be emitted from the sub-cathode towards the anode and outgasses the X-ray tube. The use of a secondary cathode for degassing does not use the X-ray tube primary cathode during processing and can extend the life of the primary cathode. Additionally, the sub-cathode can be used to detect vacuum integrity within the X-ray tube during processing and post-processing and serve as a diagnostic tool for potential X-ray tube errors and failures related to high voltages.

[0015] In this manner, the secondary cathode can eliminate the need for standard bakeout techniques for processing X-ray tubes and / or reduce the processing time to evacuate these tubes during manufacture. In on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com