Control valve for controlling pressure-medium flows comprising integrated check valve

A pressure medium and control valve technology, which is applied in the direction of valve devices, thin material processing, machines/engines, etc., can solve problems such as damage and component damage, and achieve the effect of simple methods, fixed support, and low-cost technical implementation solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

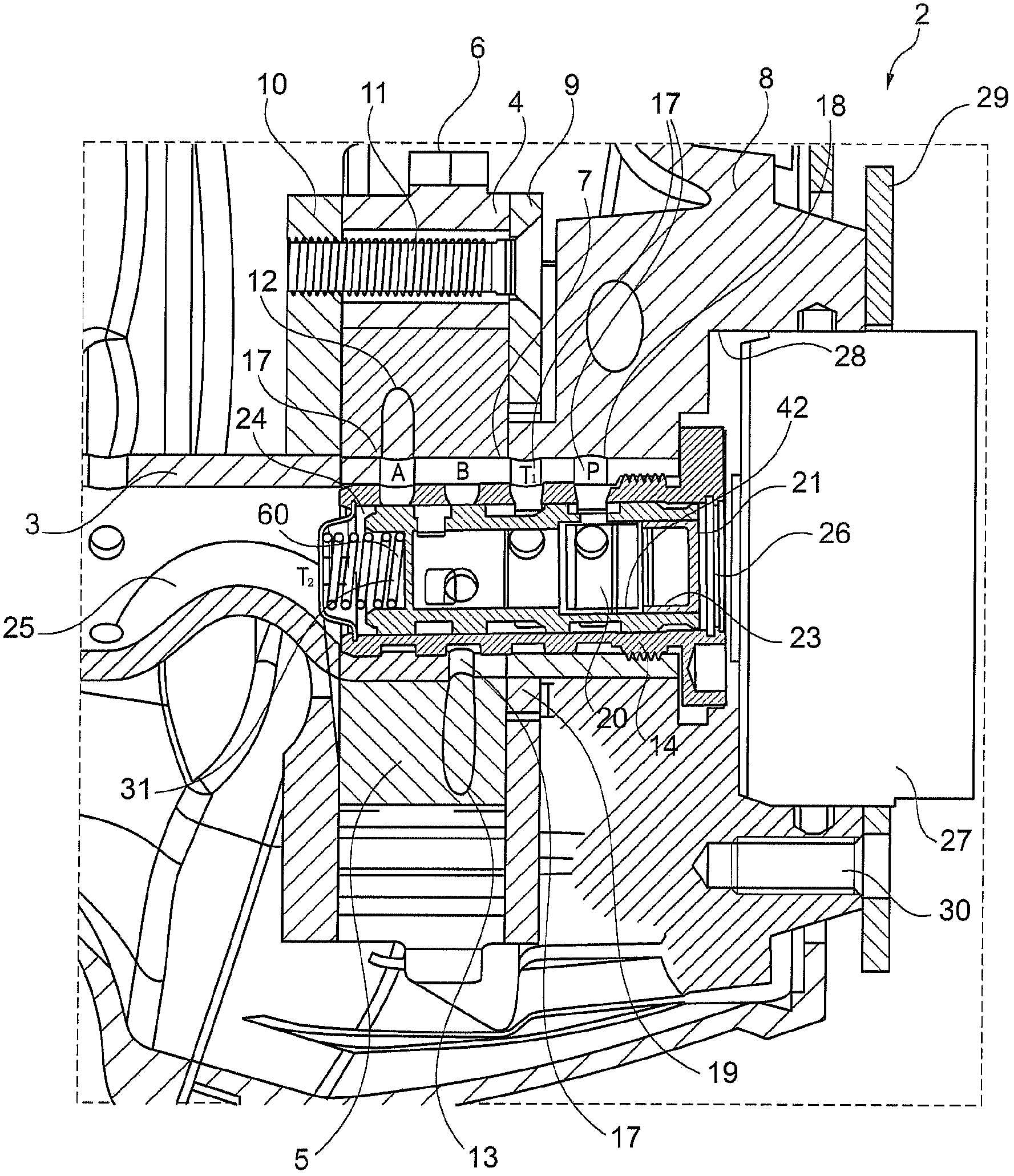

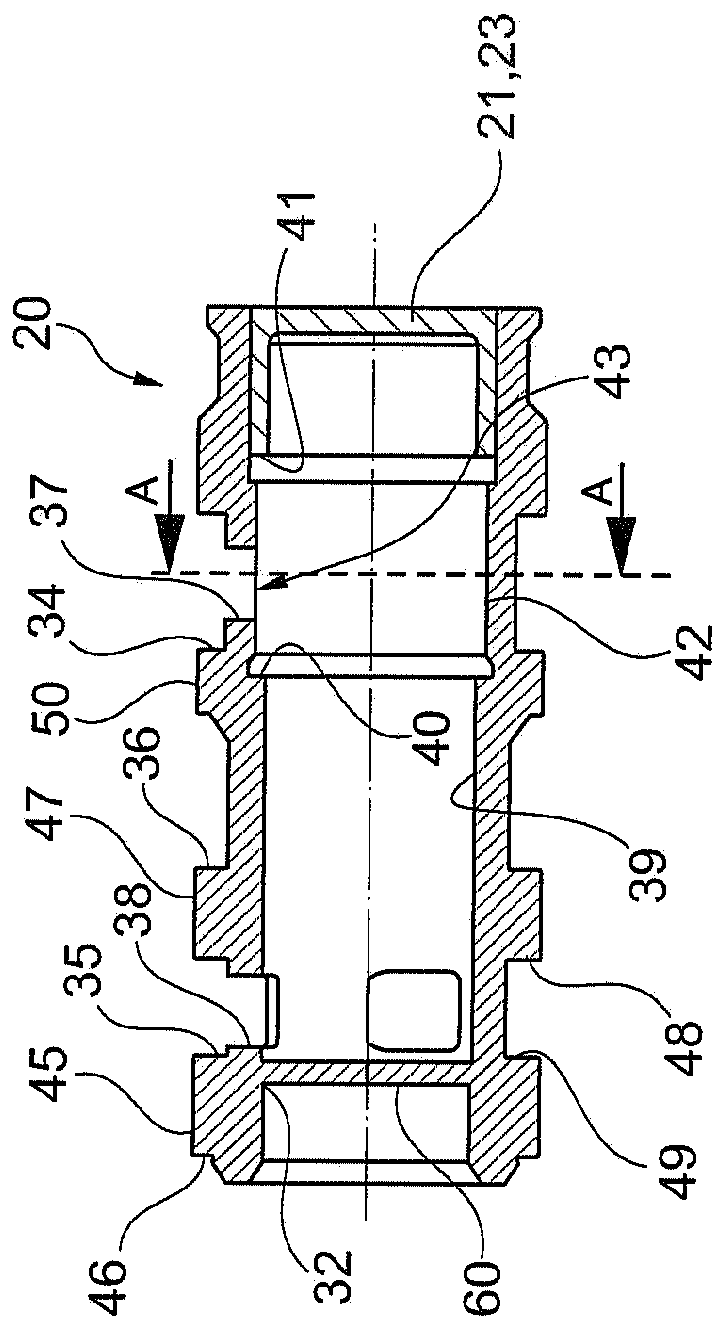

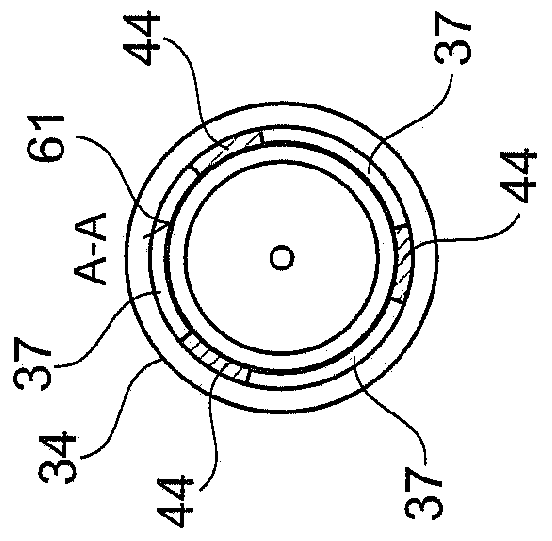

[0040] refer to figure 1 To 3, a first embodiment of the control valve according to the present invention is first explained. The control valve 1 is part of a hydraulic adjustment mechanism for a hydraulic rotary piston adjuster of an internal combustion engine, designated generally by the reference number 2 .

[0041] The rotary piston adjuster 2 comprises an outer rotor 4 in drive connection to a crankshaft (not shown) and an inner rotor 5 connected in a rotationally fixed manner to a camshaft 3 , wherein the outer rotor and the inner rotor are relative to the camshaft 3 The common axis of rotation is arranged concentrically. The outer rotor 4 is rotationally coupled to the crankshaft via a sprocket 6 and a (not shown) chain drive. It is also conceivable to drive the outer rotor 4 to the crankshaft via a belt drive or a gear drive. The outer rotor 4 is mounted on the inner rotor 5 in a rotationally adjustable manner. The inner rotor 5 has a central opening (not shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com