Pallet

A pallet and panel technology, which is applied in the field of pallets with goods turnover, can solve the problems of increasing production cost and heavy weight, and achieve the effects of increasing bearing capacity, large supporting force and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

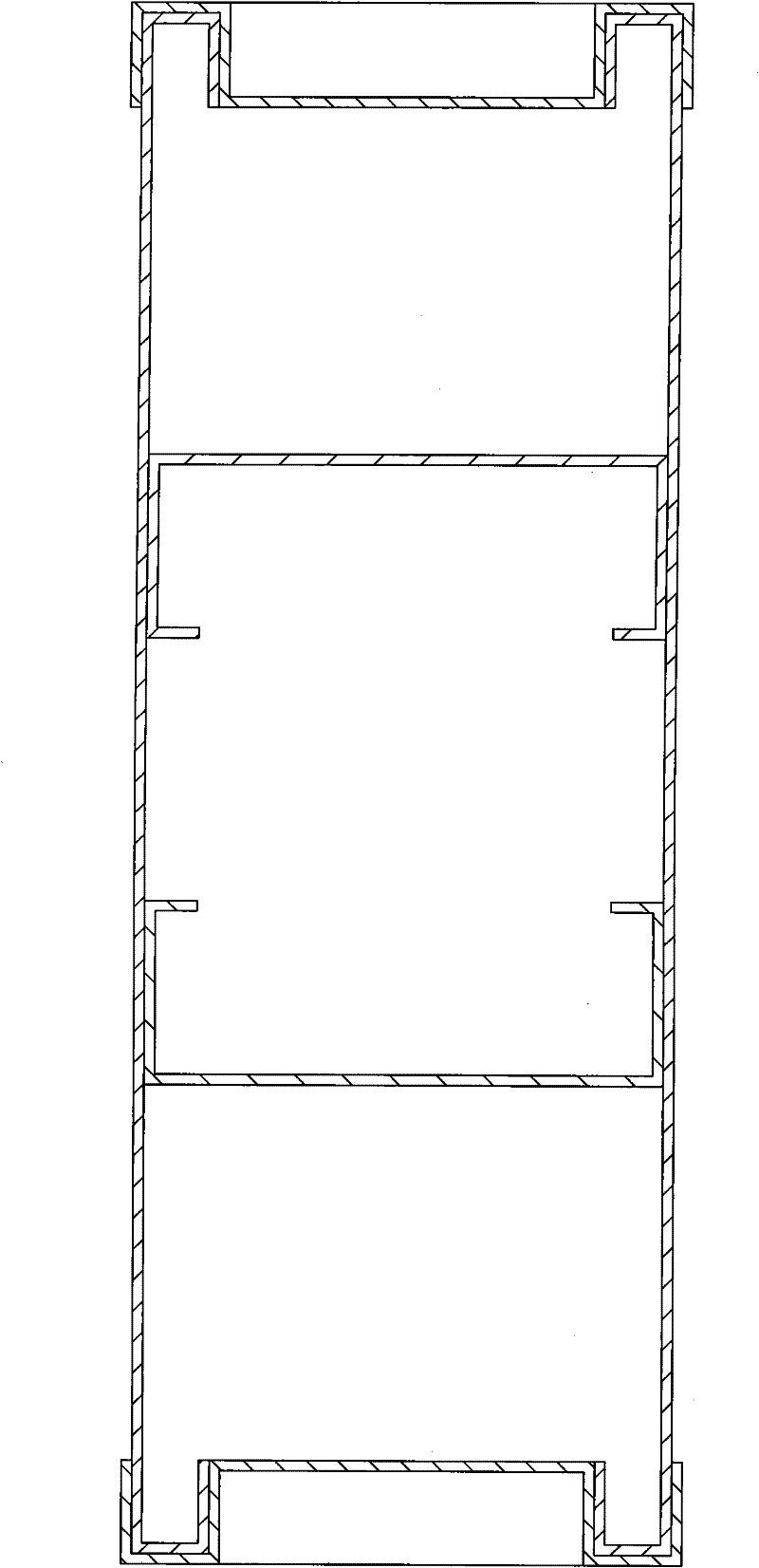

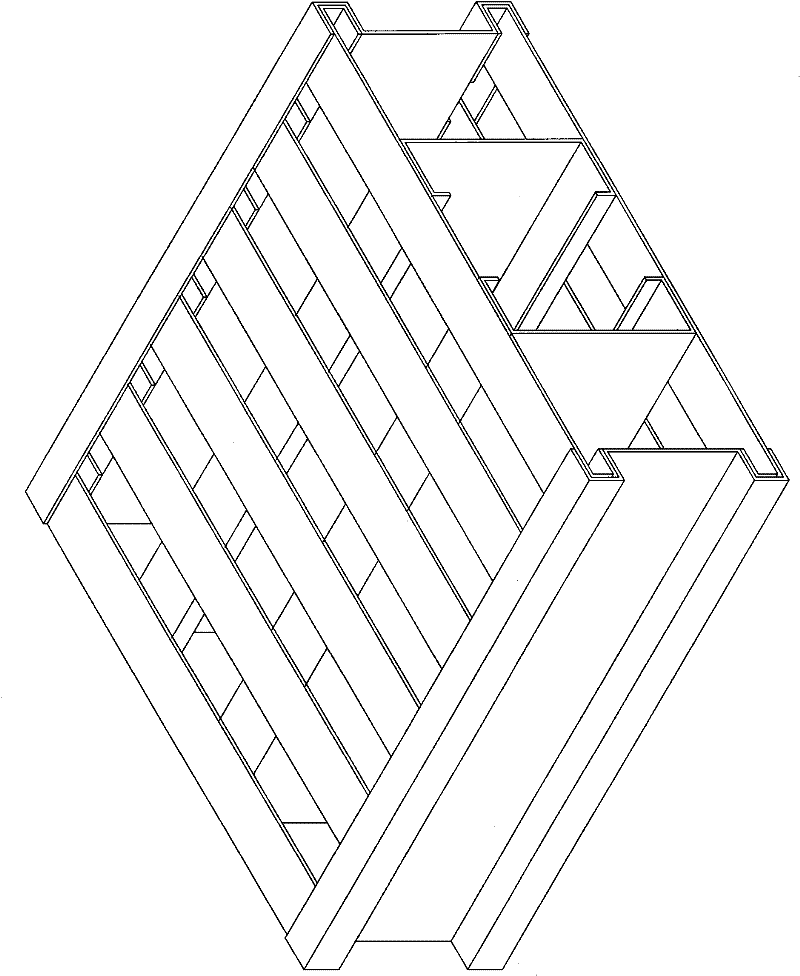

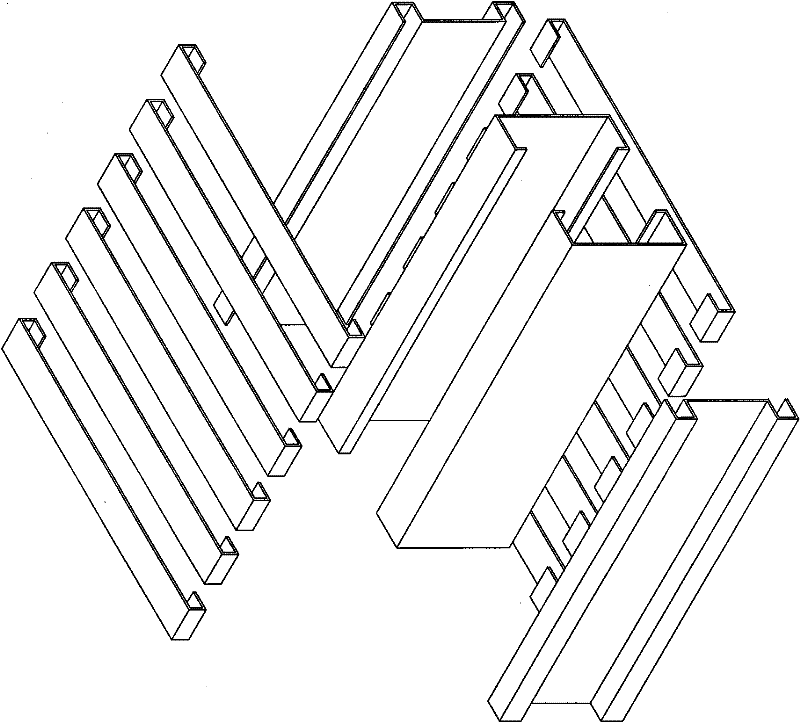

[0014] The present invention is a pallet, such as figure 1 As shown, it includes a number of C-shaped metal panels 1 that are arranged at intervals in a matrix and are arranged at intervals in a matrix, and bow-shaped metal side panels 2 that are arranged at both ends of all panels 1. One end of 1 is inserted into the bayonet socket 21, and the panel and side panels are integrally formed, such as by stamping, stretching or extrusion, etc., and the adjacent panel 1 and side panel 2 are directly clamped at the contact point. Fasten the connection by tightening, welding or screwing. Since the panel and the side panels are integrally formed, the structure is simple and the strength is increased at the same time, and the production cost is low; There are multiple contact surfaces (three contact surfaces in this embodiment) with the bayonet of the side plate, thereby increasing the bearing capacity of the pallet, so the structure of the present invention is reasonable, the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com