Hook and loop fastener flock surface and method and equipment for producing same

A technology of hook and loop and rough surface, applied in the direction of chemical instruments and methods, fasteners, applications, etc., can solve the problems of environmental pollution, insufficient peel strength, and difficult natural decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will now be described with reference to a preferred embodiment shown in the accompanying drawings.

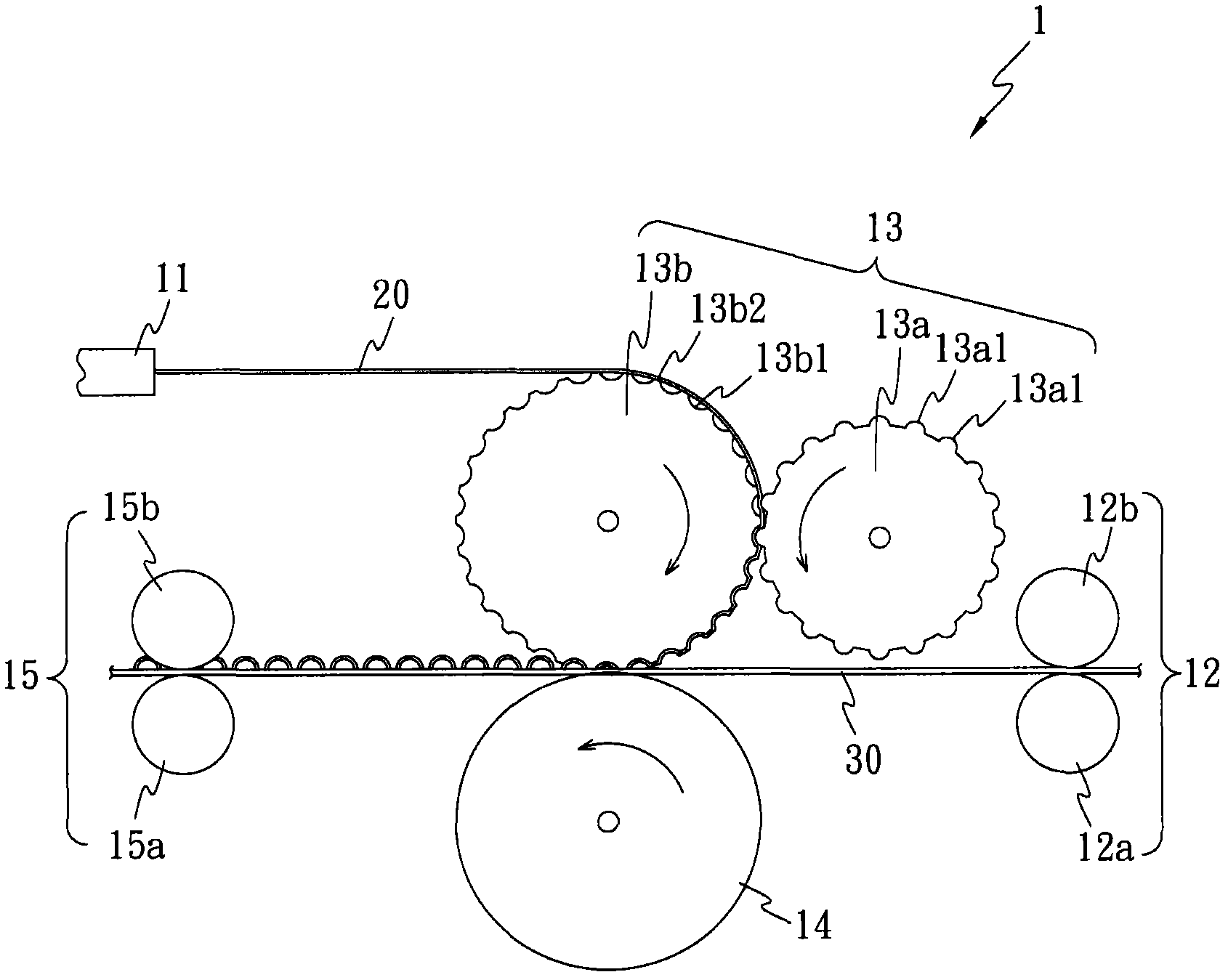

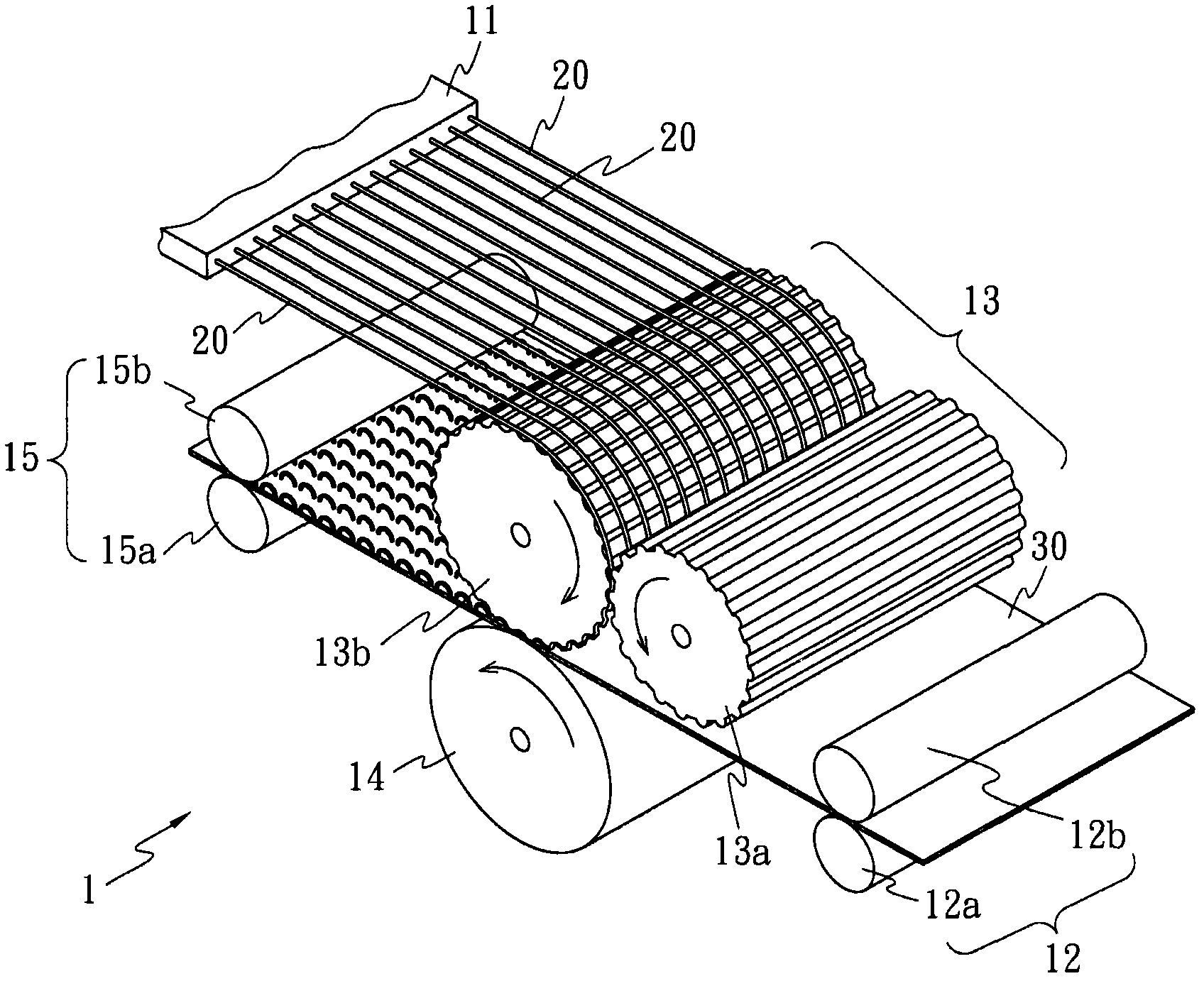

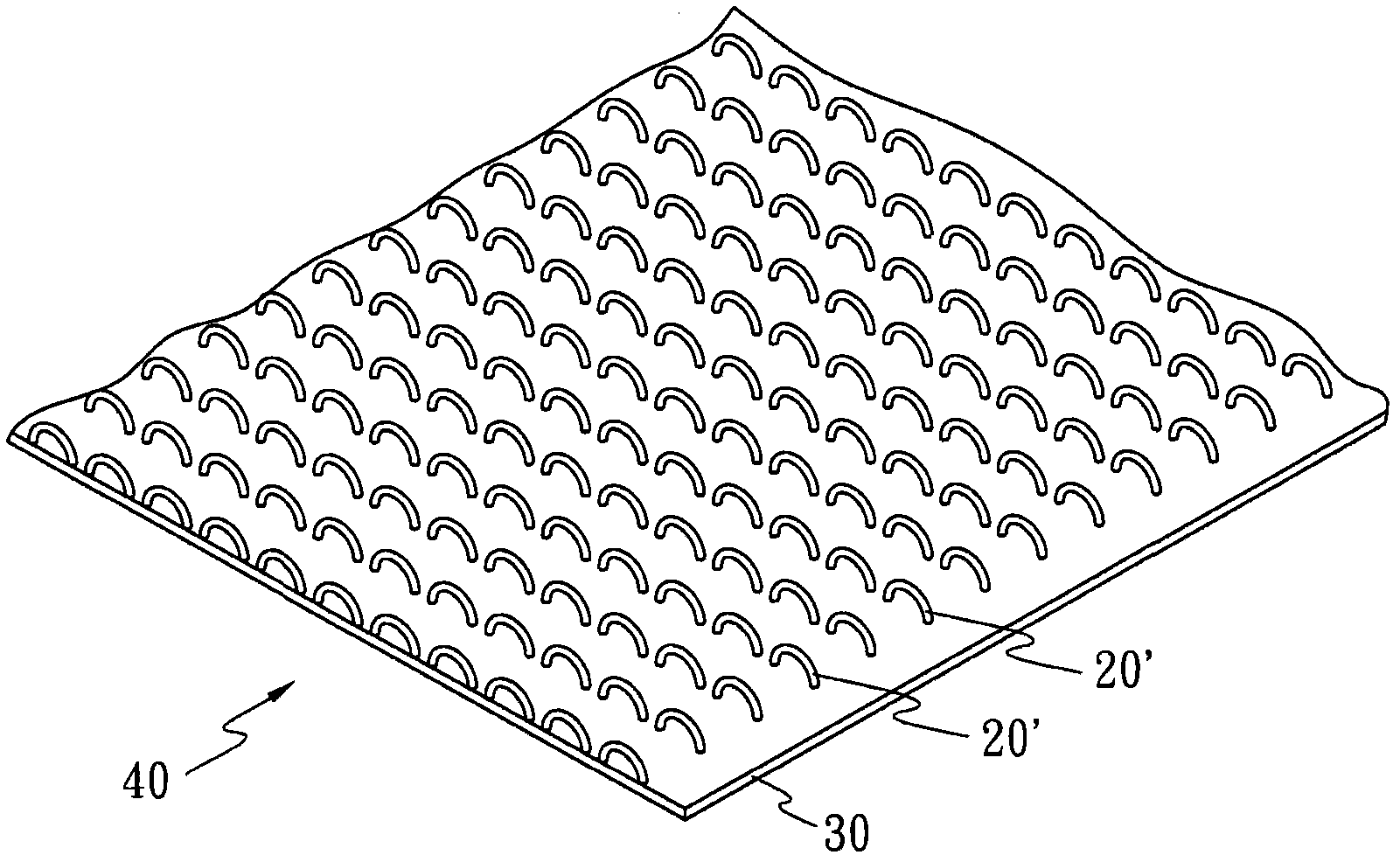

[0022] figure 1 It is a schematic side view of an apparatus for manufacturing a matte surface for hook and loop fasteners according to a first embodiment of the present invention, figure 2 is a schematic perspective view of the manufacturing facility, and image 3 It is a schematic perspective view of the matte surface of the hook and loop fastener manufactured according to the first embodiment of the present invention.

[0023] First, refer to figure 1 and 2 The apparatus for producing the matte surface for hook and loop fasteners of the present invention will be described. like figure 1 and figure 2 As shown, the device 10 for producing the matte surface of the hook and loop fastener according to the present invention mainly includes a yarn feeding device 11 , a substrate feeding device 12 , a loop forming device 13 , a loop fixing device 14 and a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap