Drum type washing machine

A technology for drum-type washing machines and washing machine shells, which can be applied to other washing machines, washing devices, textiles, and papermaking, and can solve the problems of incompatibility and manufacturing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

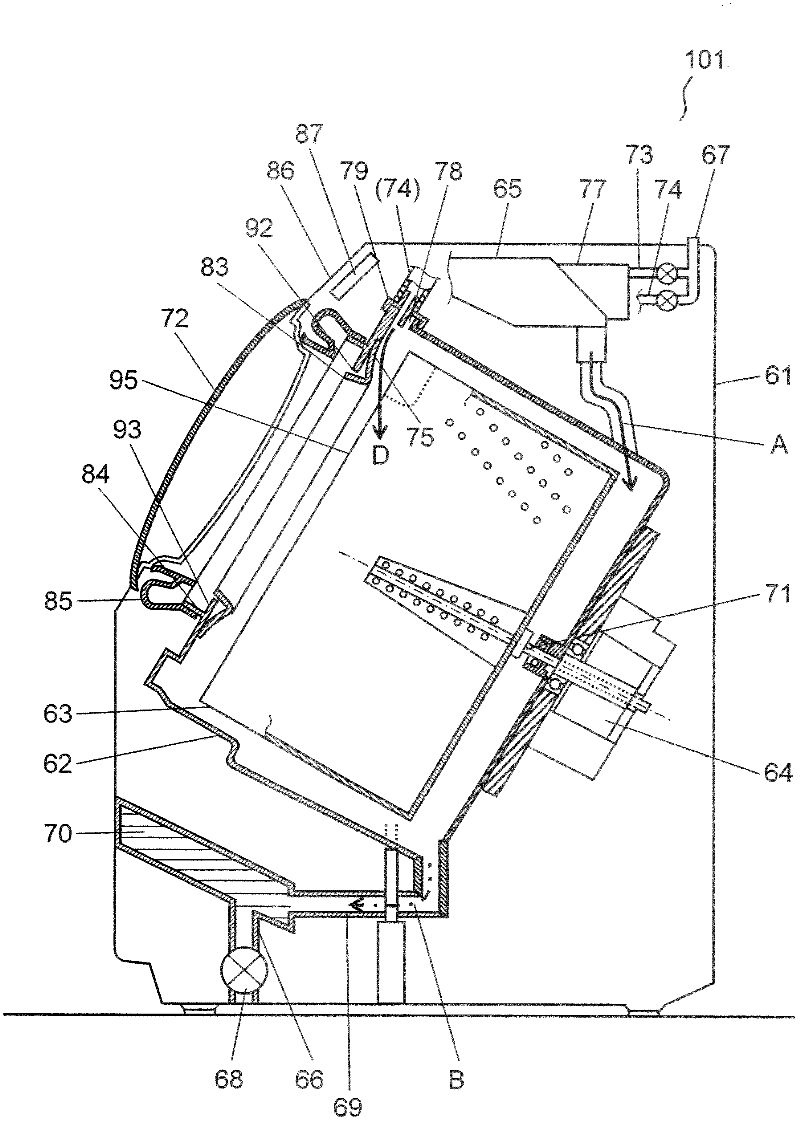

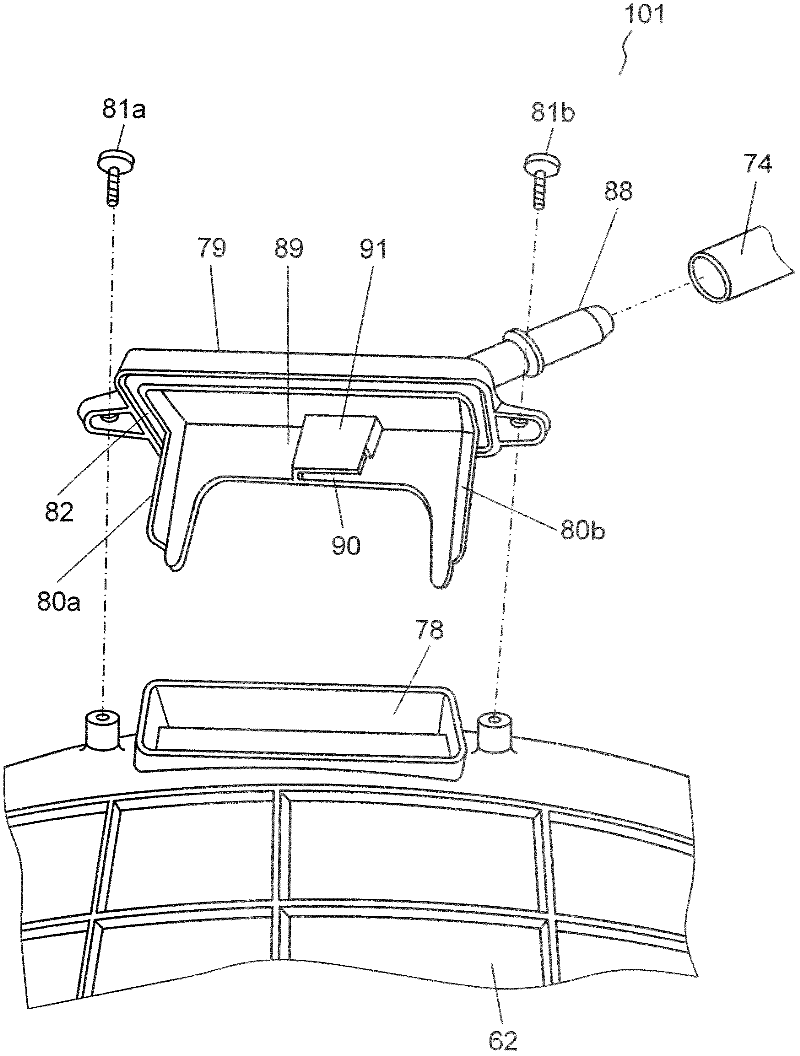

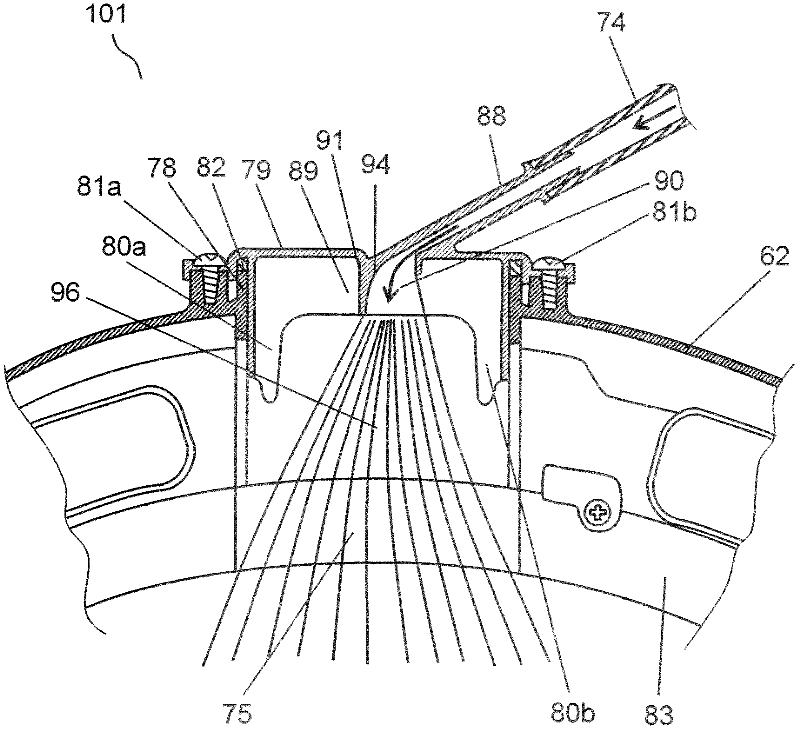

[0026] figure 1 Shown is a side sectional view of front-loading washing machine 101 in the embodiment of the present invention. Such as figure 1 As shown, the drum type washing machine 101 has a washing machine housing 61, a water tank 62, a rotating drum 63, a motor 64, a water supply device 65, a drain device 66, a water tank opening 92, a water diversion opening 78, and a spray nozzle 79. The water tub 62 is set in the washing machine casing 61 in a swingable manner. The rotary drum 63 is rotatably arranged in the water tub 62 . The motor 64 is attached to the back of the water tub 62 from the outside of the water tub 62 . That is to say, the motor 64 is fixedly installed on the outer bottom of the water tub 62 .

[0027] The drum type washing machine 101 automatically controls such as figure 1 Motor 64, water supply 65, drain 66, etc. are shown. Drum-type washing machine 101 has at least the function of performing a washing process, a rinsing process, and a dehydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com