Improved all gear crossed-axis differential

A differential and cross shaft technology, which is applied in the field of all-gear differentials, can solve problems such as the convenience of differential speeds that are rarely considered, and achieve the effect of improving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

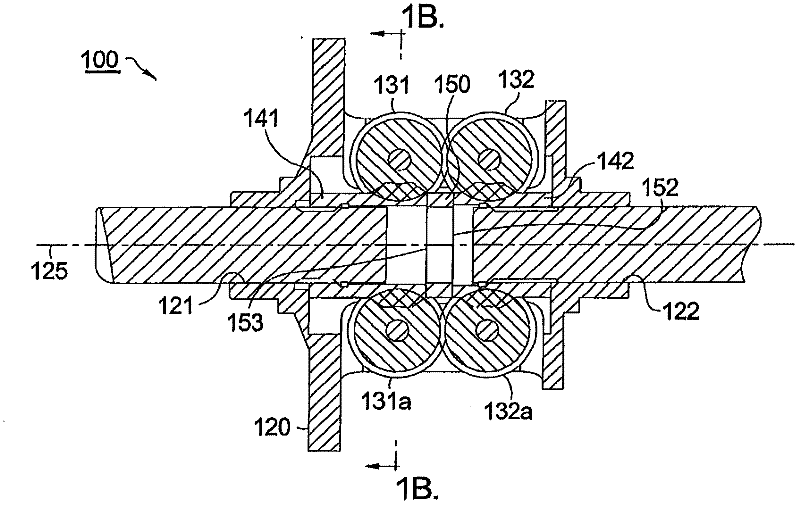

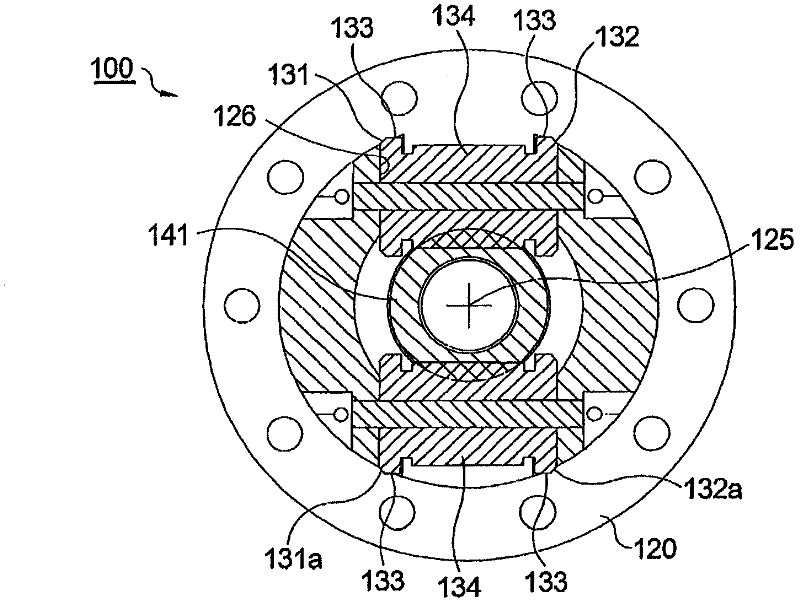

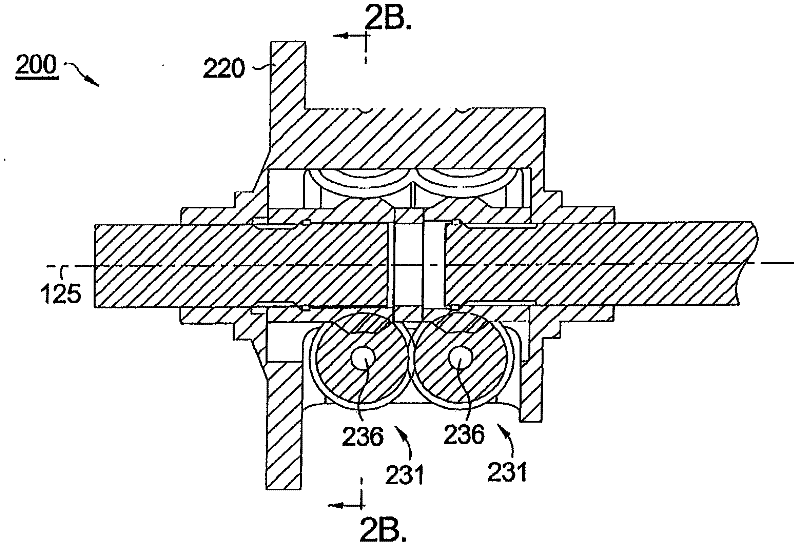

[0029] The present invention herein improves upon the prior art compact full traction differential disclosed in above-referenced US Patent No. 6,783,476 and has a similar basic structure to the prior art differential. Therefore, first refer to Figure 1a and 1b , which shows two views of a complete spider gear assembly with only two sets of balance gears according to the first exemplary embodiment of the differential 10 according to the invention.

[0030] Housing 120 is preferably made of formed or cast metal and has only three openings, a first set of appropriate openings 121 aligned along first axis 125 for receiving respective inner ends of output shafts (not shown). , 122, and only a single further opening 126, which is rectangular and extends directly through the housing 120 and is centered perpendicular to the axis 125, thereby creating two what is considered in the art to receive The opening of the "window" of the combined gear pair.

[0031] Each of the two pairs o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com