Suspension device with front and back torsion bars for automobile

A suspension device and rear suspension technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of restricting implementation, difficult implementation, complex structure, etc., and achieve the effect of improving shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

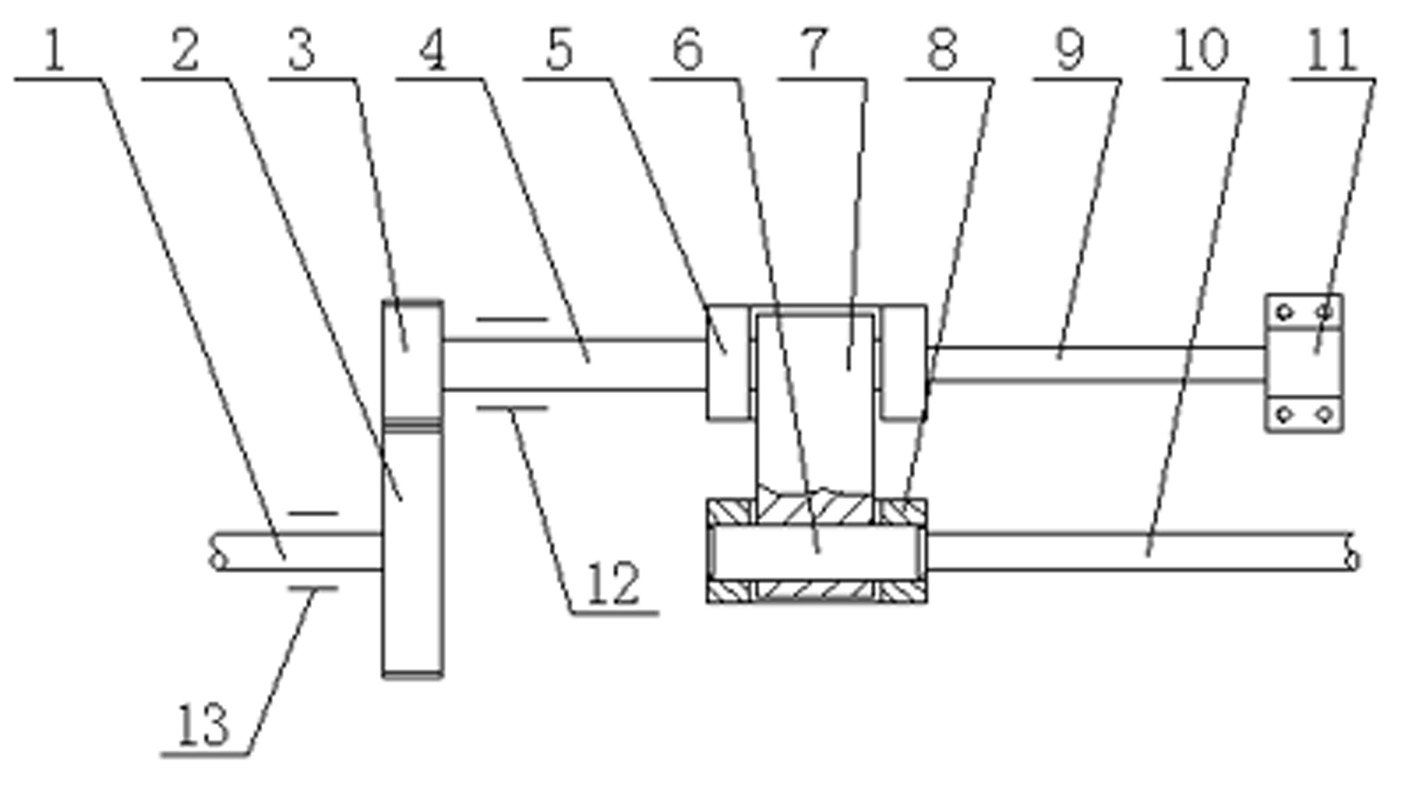

[0022] Such as figure 1 , 2 As shown, the left end of the front torsion bar spring 1 is connected with the control arm of the front suspension of the automobile, the right end of the front torsion bar spring 1 is fixedly equipped with the front torsion bar gear 2, and the force transmission gear 3 meshing with the front torsion bar gear is fixed on the The left end of the power transmission shaft 4 and the right end of the power transmission shaft 4 are fixedly installed on the connecting rod III5, and the reset torsion bar spring 9 is fixedly installed coaxially on the opposite side of the connecting rod III with the power transmission shaft, and the right end of the reset torsion bar spring It is fixedly installed on the vehicle frame through the fixing seat 11. The purpose of installing the reset torsion bar spring is to make the front torsion bar spring and the rear torsion bar spring reset quickly after torsional deformation.

Embodiment 2

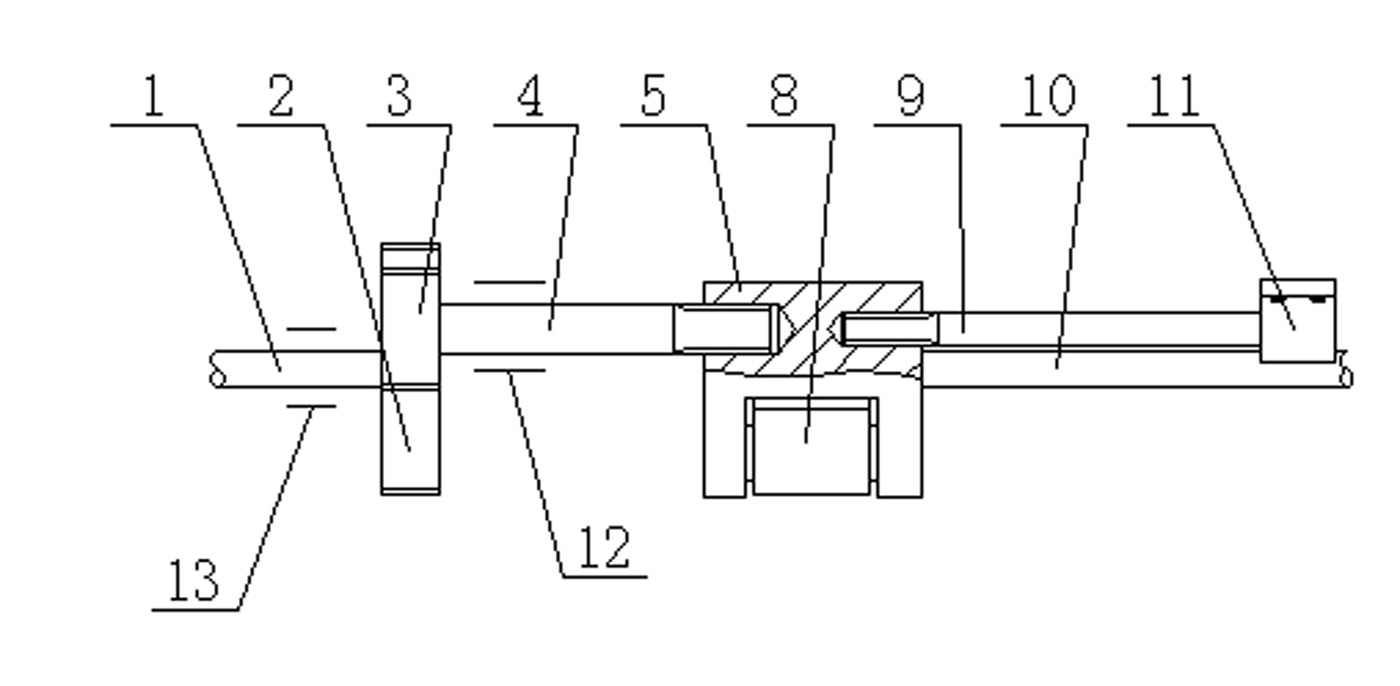

[0024] Such as image 3 As shown, on the basis of Embodiment 1, the installation position of the reset torsion bar spring 9 can be changed from being fixed on the connecting rod III5 to being fixedly connected with the power transmission gear 3, that is, the left end of the power transmission gear is fixedly connected with The reset torsion bar spring is fixedly connected with the power transmission shaft 4 at the right end of the power transmission gear, and the reset torsion bar spring is coaxial with the power transmission shaft.

Embodiment 3

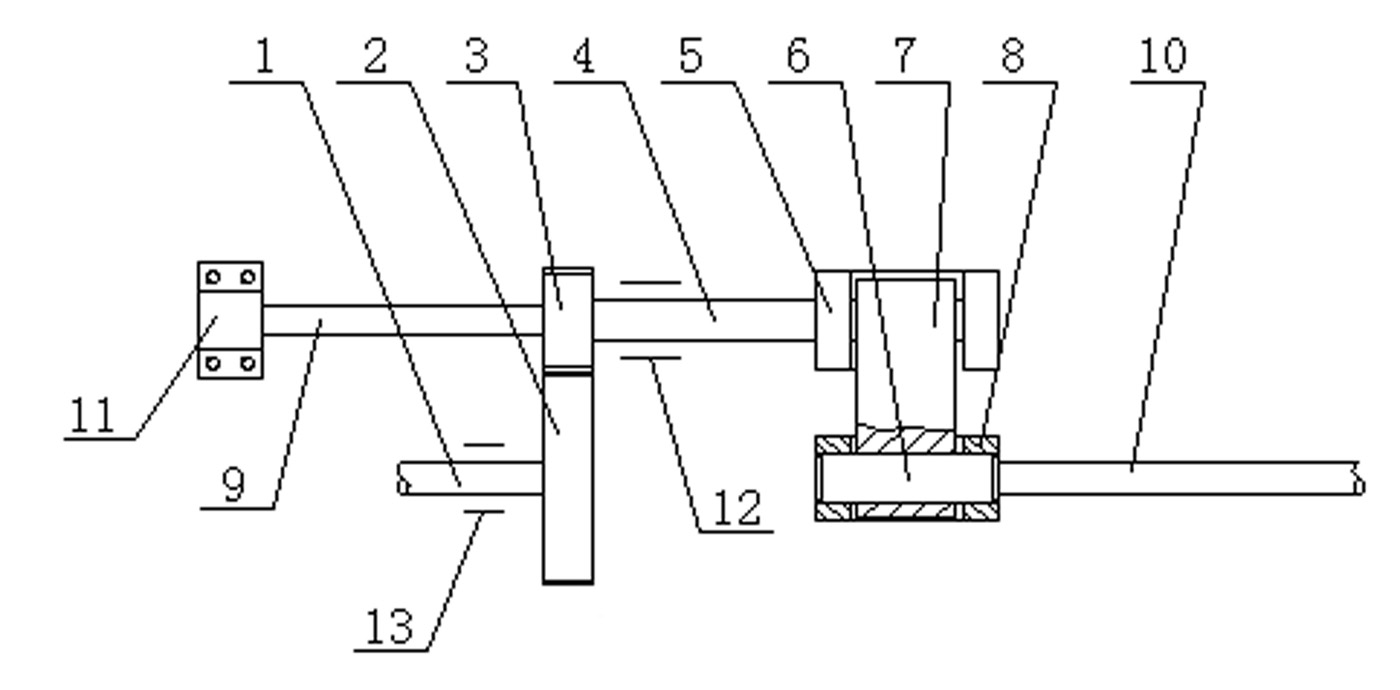

[0026] Such as Figure 4 Said, the right end of rear torsion bar spring 10 is connected with the rear suspension of automobile, the left end of rear torsion bar spring 10 is fixedly installed with rear torsion bar gear 14, the left end of front torsion bar spring 1 is connected with the control arm of automobile front suspension, The right end of the front torsion bar spring 1 is fixedly connected on the connecting rod I8, and other structures are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com