Pivotable propeller nozzle for a watercraft

A propeller and nozzle technology, applied in ship propulsion, steering with jets, hull, etc., can solve problems such as connection instability, and achieve the effects of low material cost, high bending moment, and good torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In the different embodiments described in the following figures, the same constituent parts have the same reference numerals.

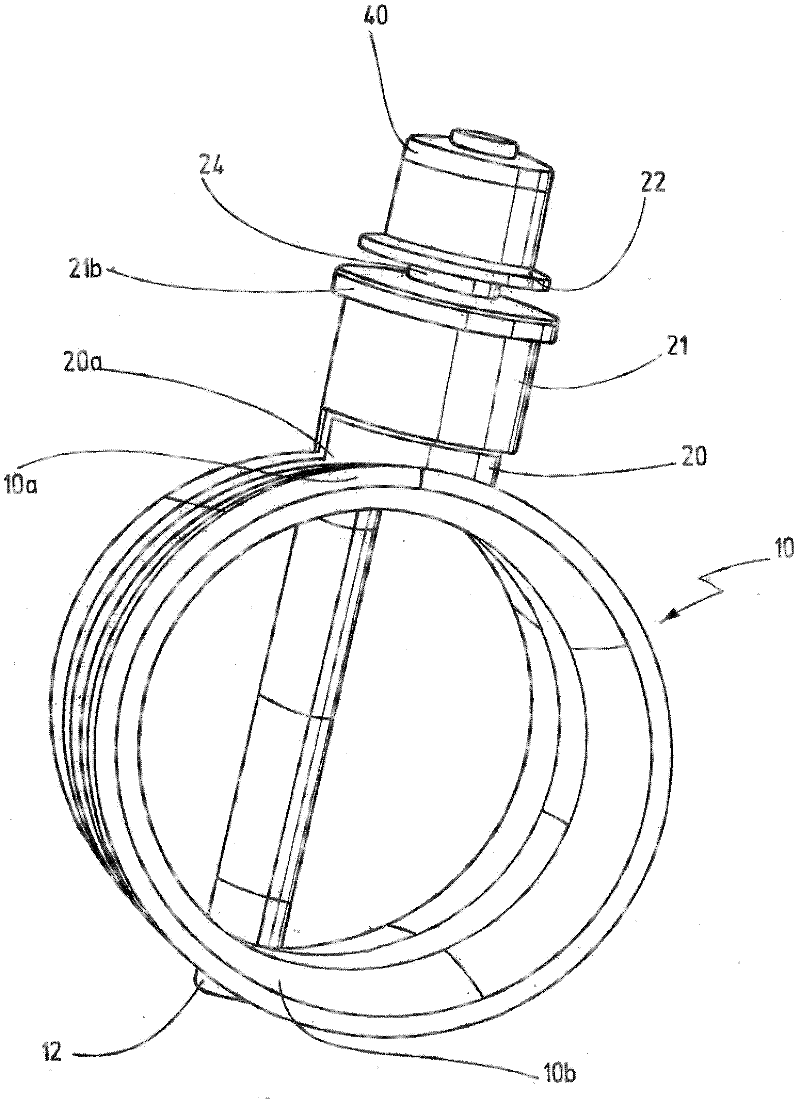

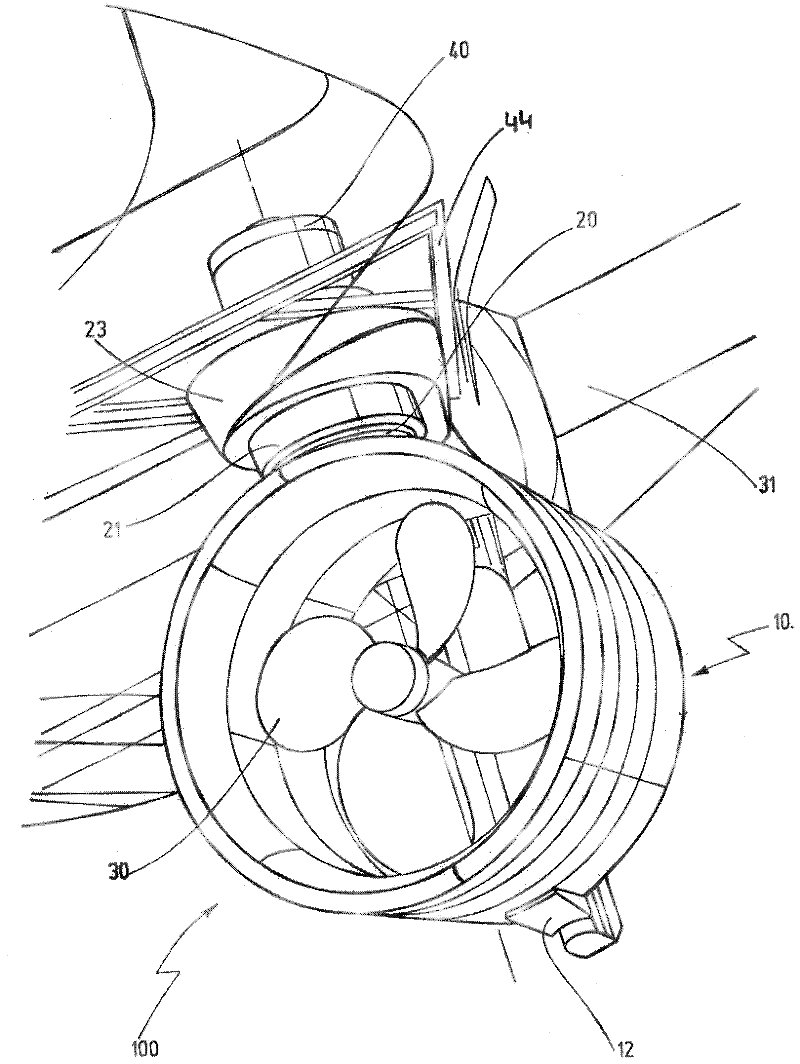

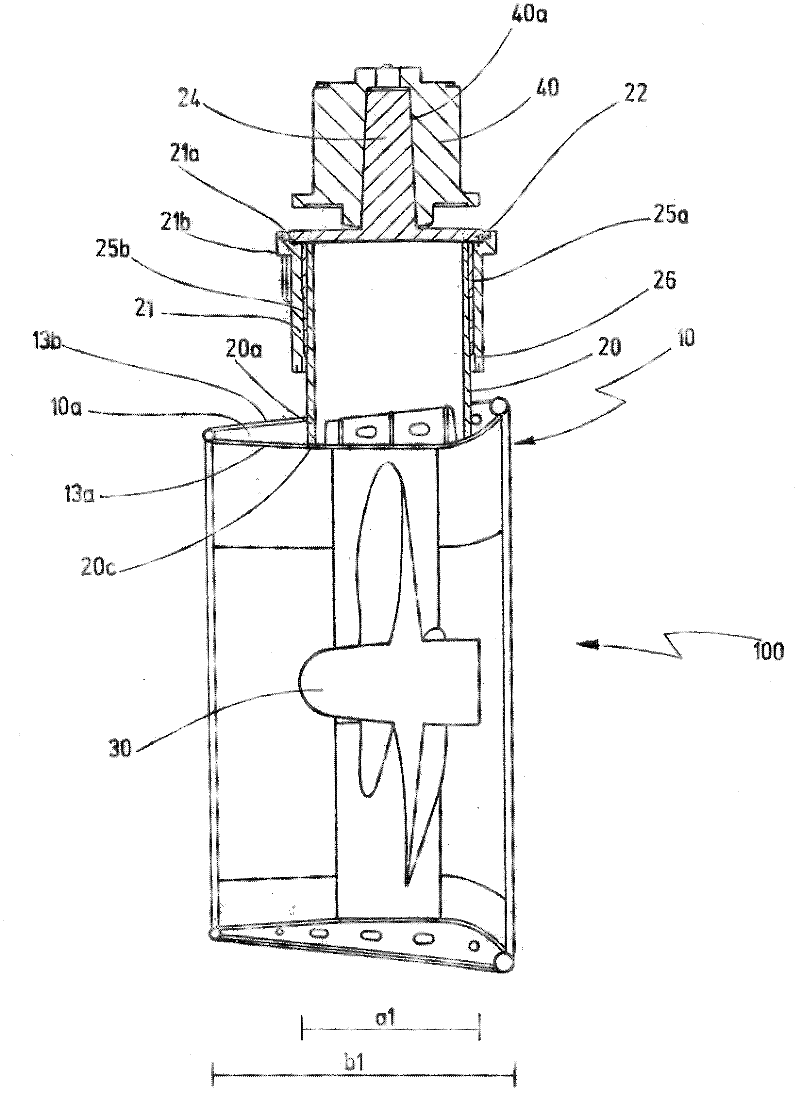

[0071] figure 1 A nozzle ring 10 of a propeller nozzle is shown, which has a nozzle shaft 20 designed as a hollow cylinder. To provide a better viewing angle, the propeller is omitted. exist figure 2 The same nozzle ring 10 is shown in the installed state (i.e. mounted on a vessel), i.e. in figure 2 The midship propeller 30 is arranged inside the nozzle ring 10 . In order to provide a better perspective, the figure 2 The propeller shaft is omitted in . Only the vessel body 31 of the vessel is shown in this region, ie in this region the nozzle stems are mounted at the same location. At the same time, the vessel body 31 is partly drawn transparent, so the swing drive 40 and its connection structure 44 on the vessel body 31 that is placed on the nozzle rod 20 and constitutes a rotating vane steering unit can be partially seen. The swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com