Light bulb containing an illumination body that contains carbide

A technology of illuminants and incandescent lamps, which is applied in the field of halogen incandescent lamps, can solve problems such as inability to perform process management, and achieve the effect of improving closing stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

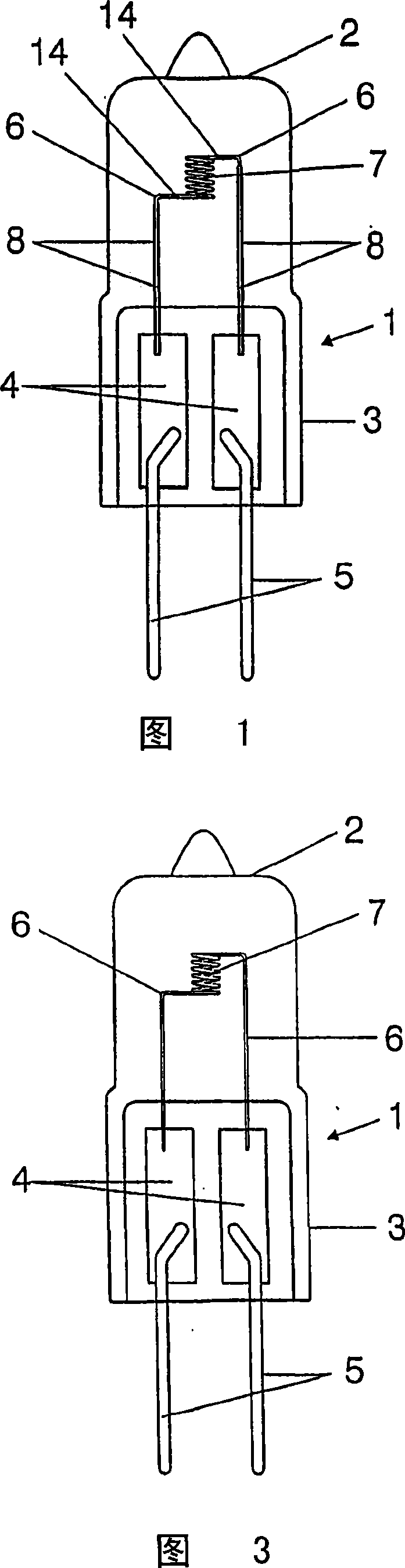

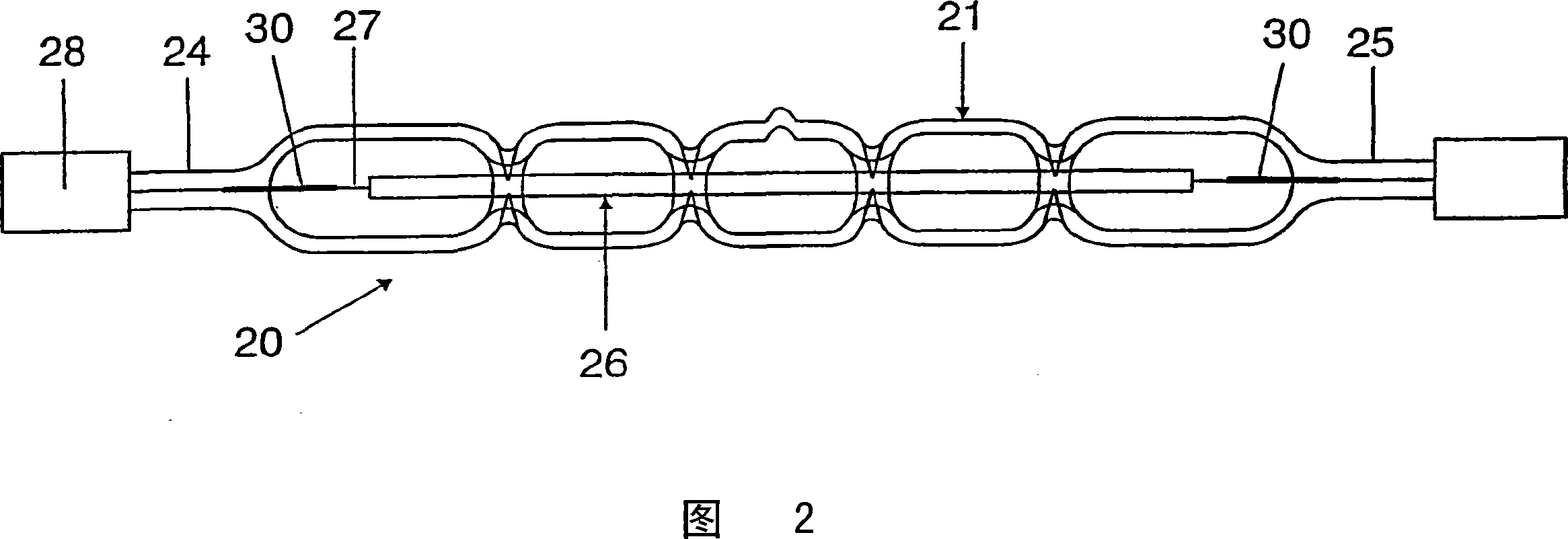

[0034] FIG. 1 shows a one-sided extruded incandescent lamp 1 with a bulb 2 made of quartz glass, an extruded part 3 and an inner feeder 6 connecting the film 4 in the extruded part 3 with the The illuminants 7 are connected. The illuminant is a simply wound, axially arranged wire of TaC, the unwound end 14 of which extends across the lamp axis. The external leads 5 are attached externally to the foil 4 . The inner diameter of the bulb is 5mm. The helical filament end 14 is then bent parallel to the lamp axis and forms there the elongated inner power supply line 6 as a whole. The feeder 6 is provided with a coating 8 over at least a part of its entire length, which part does not exceed 2000° C. in operation. The coating is composed of the materials described below.

[0035] Example of a first implementation form:

[0036] For example, the metals rhenium (melting point: 3453k), ruthenium (melting point: 2583K), osmium (melting point: 3318k), and iridium (melting point: 2683...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com