Component produced by additive manufacturing and having support structure

A support structure and additive manufacturing technology, applied in the field of components, can solve problems such as surface damage of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

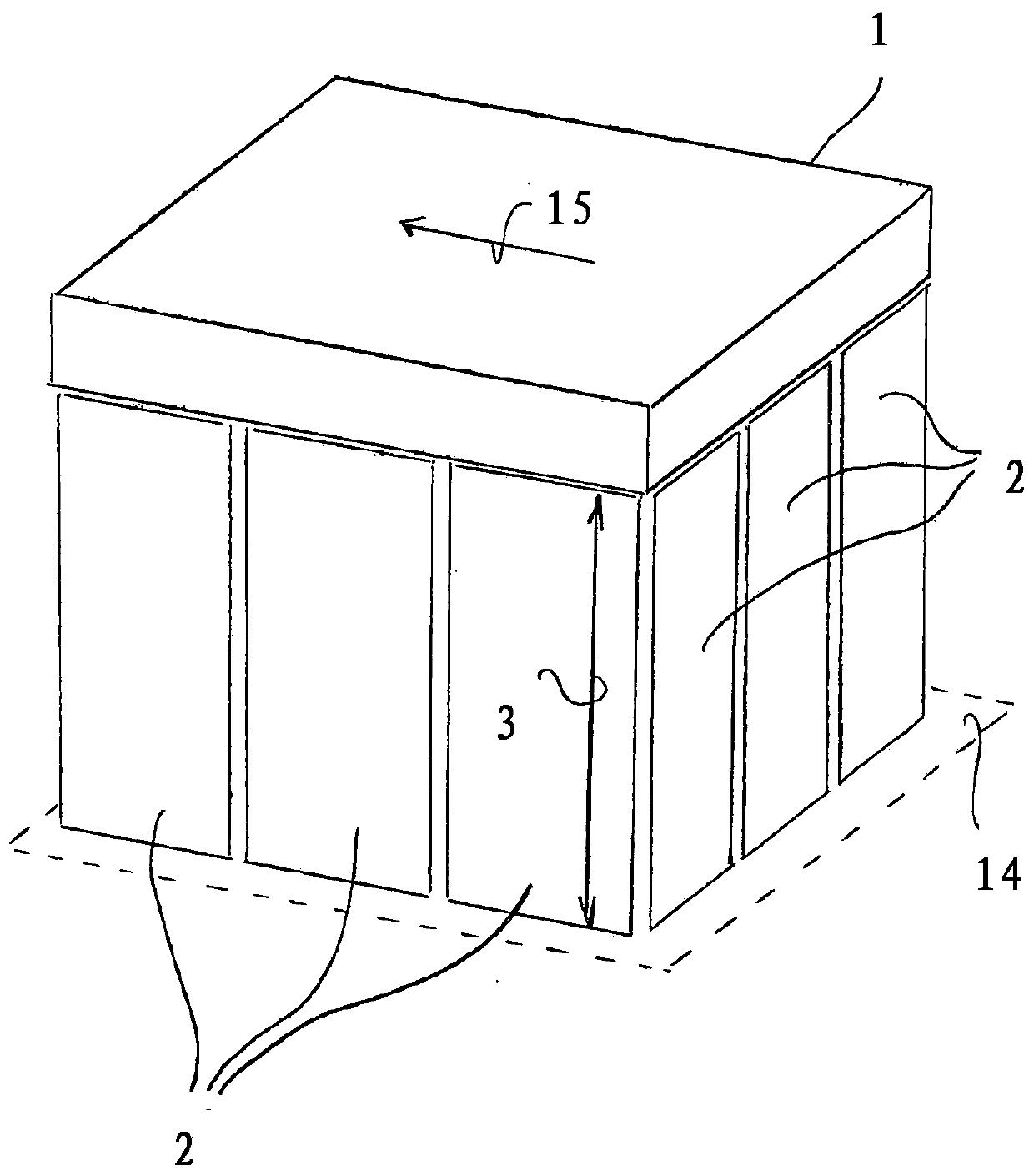

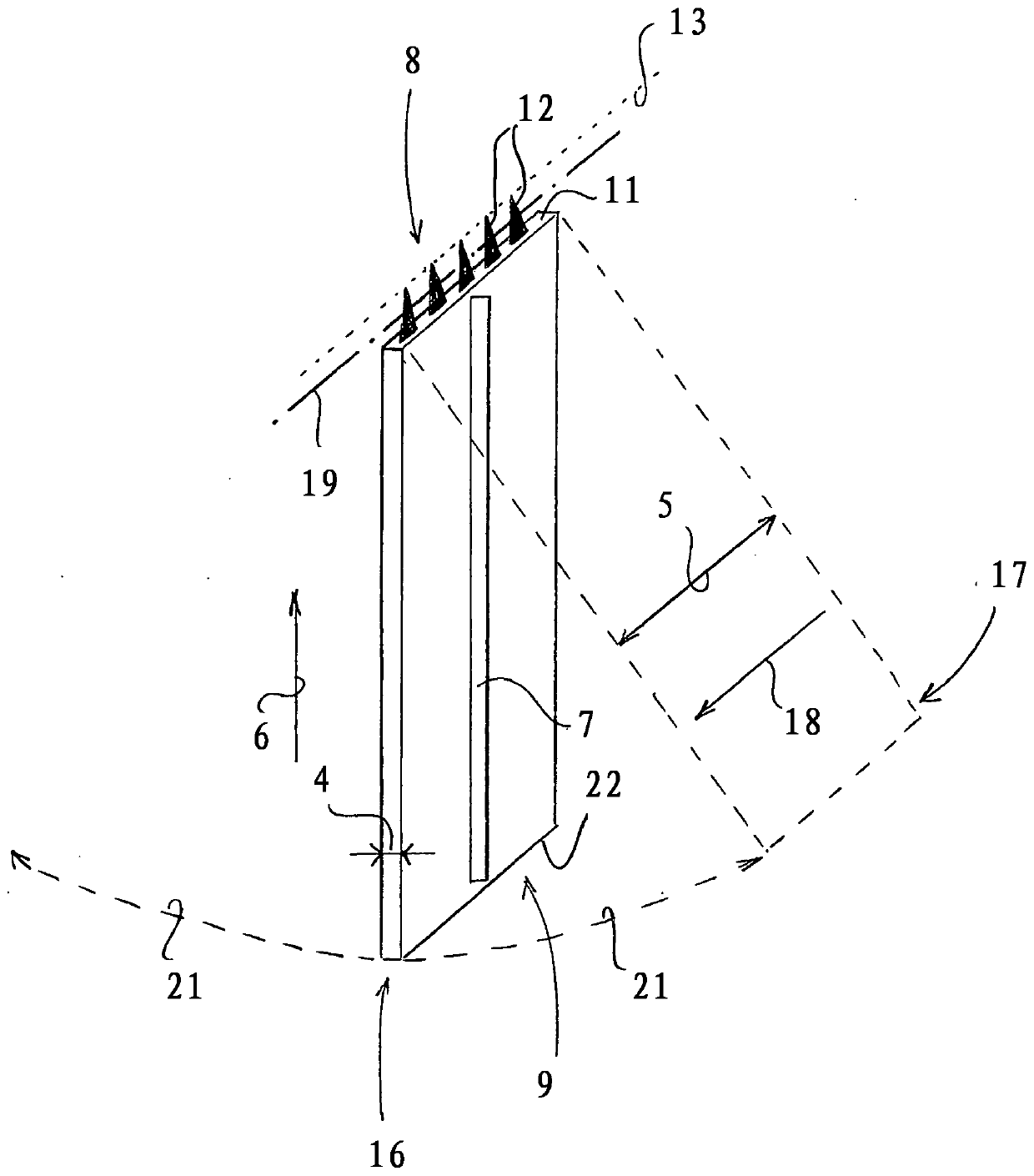

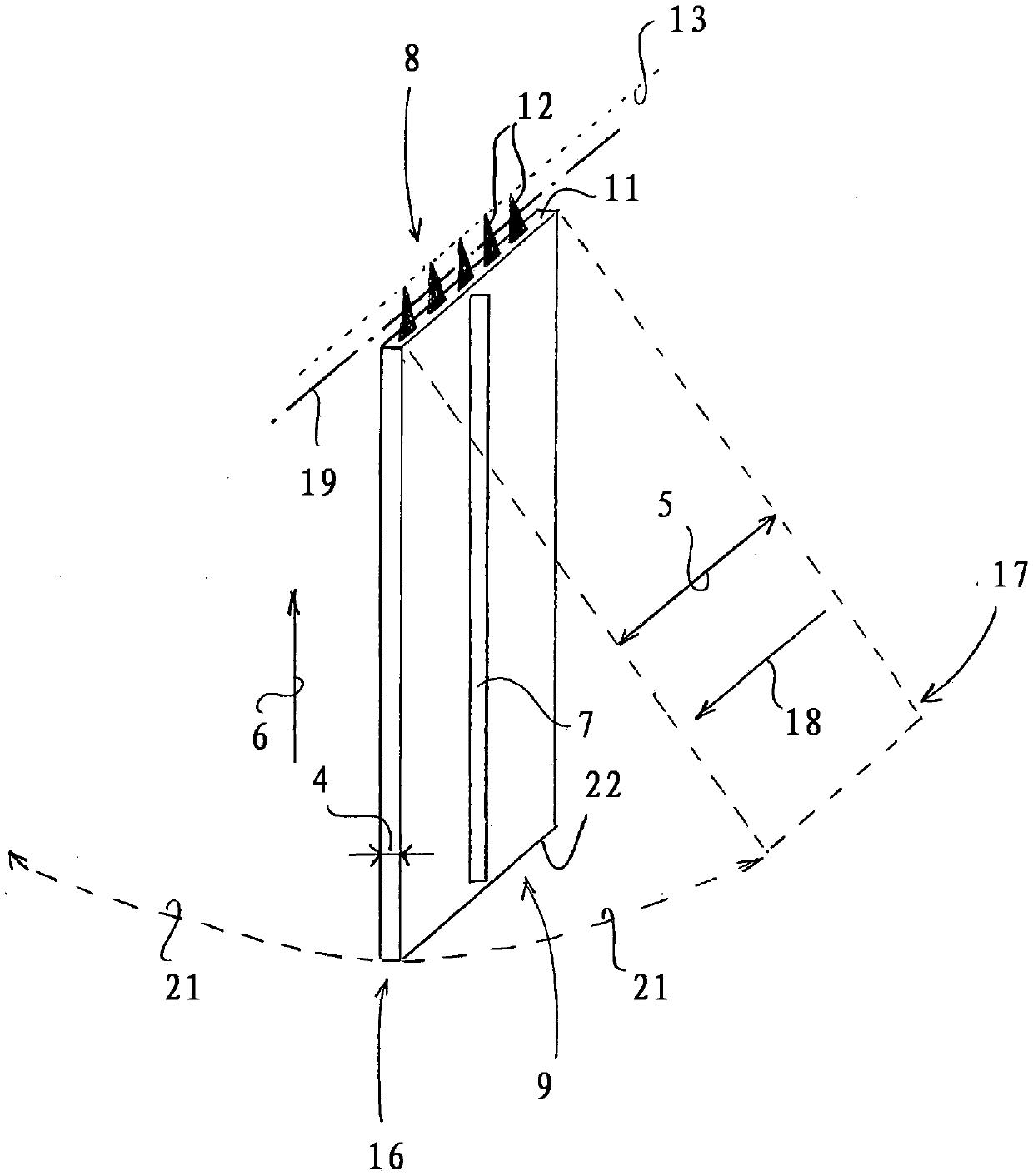

[0029] All the figures do not show the invention to scale, but only schematically and only essential components thereof are included here. The same reference numbers correspond to elements of the same or similar function.

[0030] During the powder-based additive manufacturing of the component 1 , which is not further described, it is necessary to simultaneously construct the form of the support wall 2 using suitable computer-generated CAD data and by means of the usual manipulations for a person skilled in the art with the aid of suitable computer software. support structure. Suitable powders, for example made of metallic materials, are used as structural material for the component 1 and the support wall 2 .

[0031] Overall, a plurality of support walls 2 spaced apart from one another and not connected to one another are provided for the component 1 . Here, the length 3 of the individual support walls 2 is considerably greater than their height 4 and width 5 . The support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com