Method and device for starting an internal combustion engine

A technology for internal combustion engines and starting torque, applied in the direction of internal combustion piston engines, motor starters for engines, combustion engines, etc., can solve problems such as limitations and cost that cannot be realized meaningfully

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] Before explaining the embodiments in detail, the prior art is shown first.

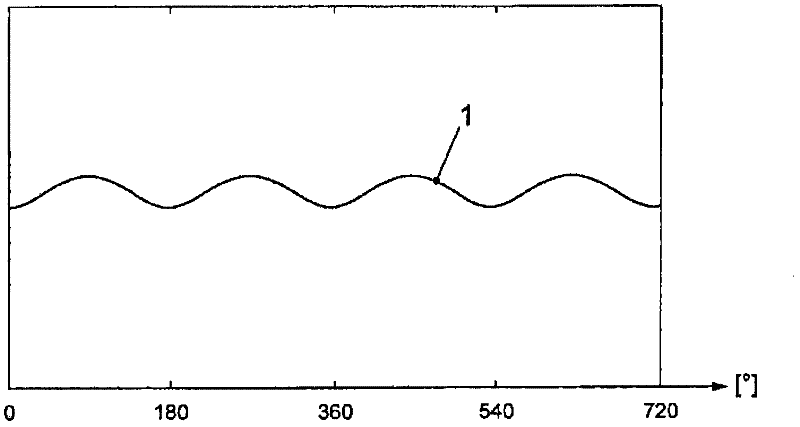

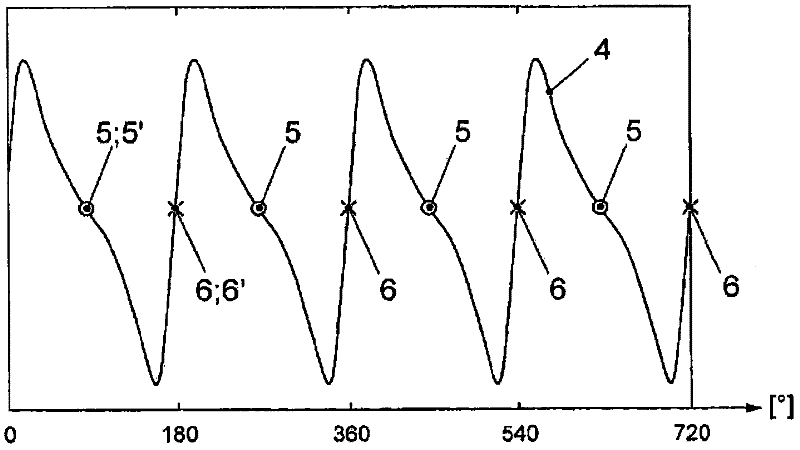

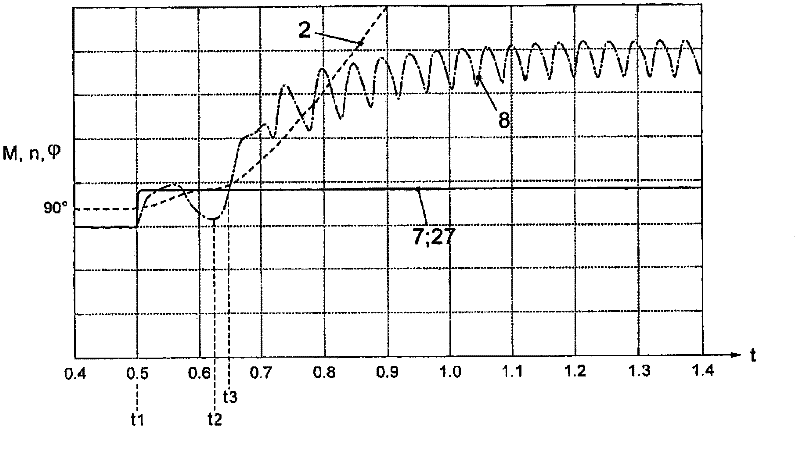

[0104] figure 1 Shows the curve of the sliding friction torque 1 over one working cycle of a four-cylinder four-stroke engine. Here, the duty cycle includes, for example, also image 3 The angular range of 0° to 720° is shown in crankshaft angle 2. In this case, the sliding friction torque 1 is essentially composed of two components. If the starting friction torque is overcome, then at Figure 7 Sliding friction occurs at the friction points of the internal combustion engine 3 shown in , in particular at the cylinder running surfaces and bearings. In principle, this brings about a braking of the rotational movement of the crankshaft. The frictional force acting between the piston and the working surface of the cylinder is converted into a frictional torque by the crankshaft drive, which fluctuates during the working cycle. Thus, the sliding friction moment 1 is obtained at figure 1 The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com