Hydraumatic variable force buffer

A buffer and hydraulic technology, applied in the field of hydraulic variable force buffer, to achieve the effect of easy operation, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings of the specification, but the scope of protection claimed by the present invention is not limited to the scope described in the embodiments.

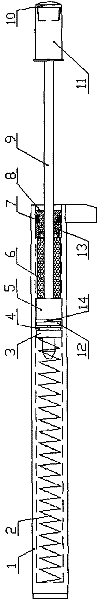

[0027] Such as figure 1 As shown, the hydraulic variable force buffer of the present invention includes an oil cylinder 1, a spring 2, a piston assembly, and a sealing system. The piston assembly includes a spring seat 3, a small convex flat ring 4, a small convex flat ring 12, a piston 5 and an iron rod 9. The sealing system includes an oil-absorbing sponge 6, an inner sleeve 11, a B-type sealing ring 7, an outer stopper 8, a small Y ring 13, and an energy-absorbing rubber head 10. The spring seat 3 has a protruding small shaft 32 inserted into the spring 2 hole to prevent the spring from sliding and increase the service life of the spring;

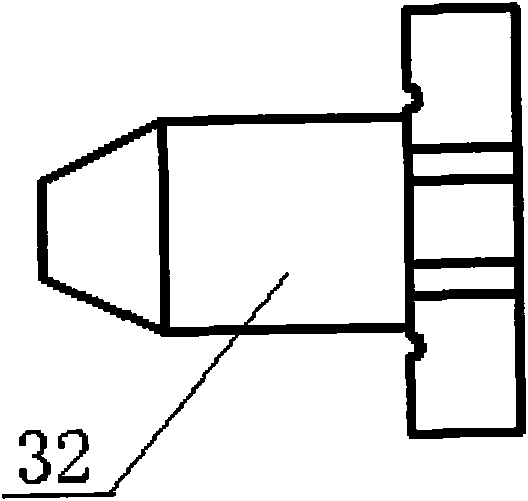

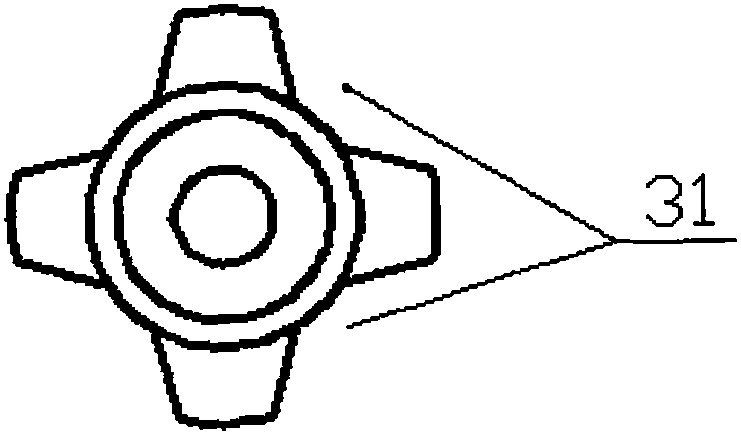

[0028] Such as figure 2 and image 3 As shown, the spring seat 3 is provided with four notch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com