Oscillating bar crank isolating valve

A cut-off valve and crank technology, applied to blast furnace parts, furnaces, heating furnaces, etc., can solve problems such as easy jamming, affecting operation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

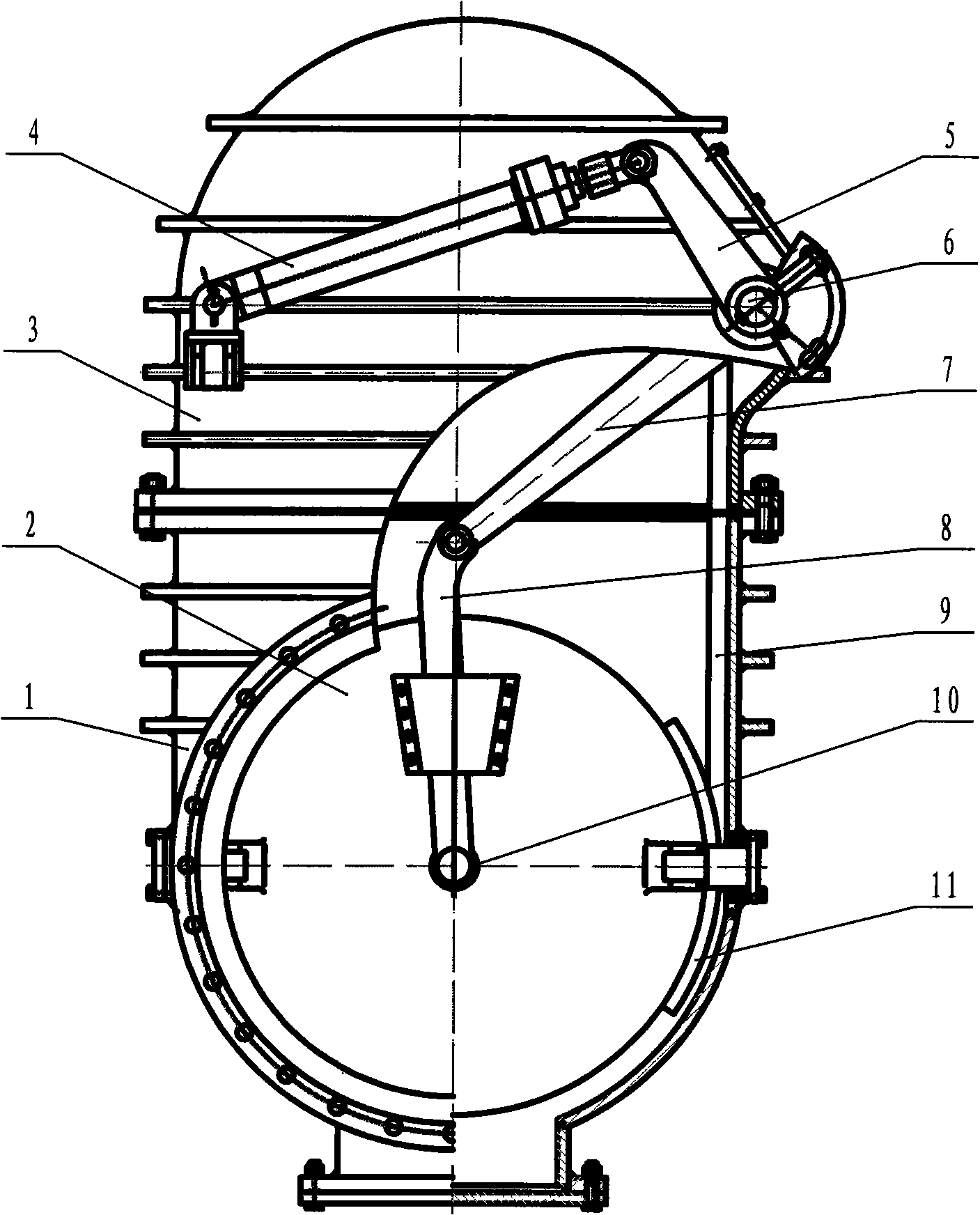

[0015] Such as figure 1 As shown: the crank cut-off valve includes a valve body 1, a valve cover 3, a gate plate 2 and a hydraulic drive device 4.

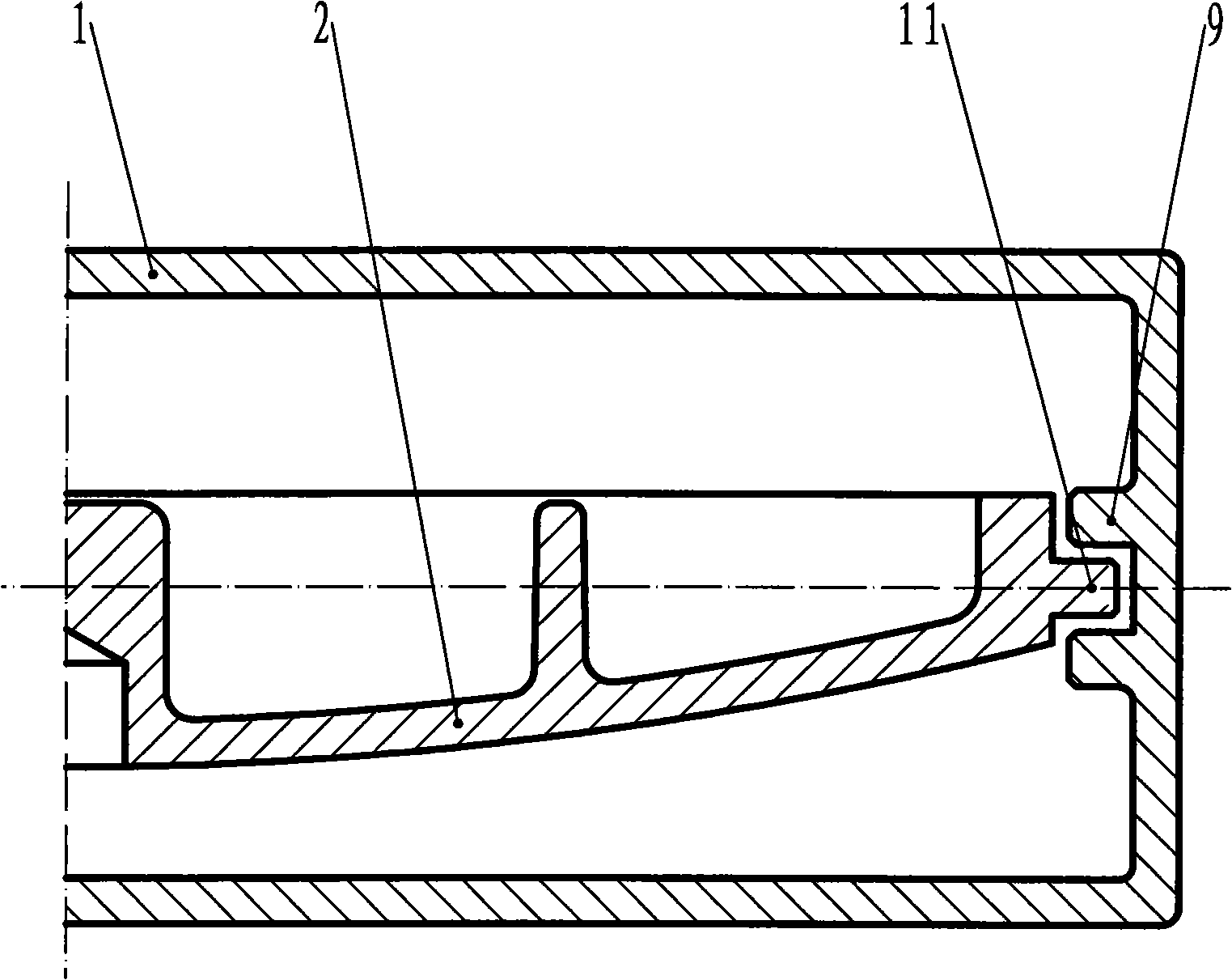

[0016] The opening and closing device of flashboard 2 is a crank swing rod mechanism, which includes crank 5, crank shaft 6, lever 7 and swing rod 8, crank 5, lever 7 and crank shaft 6 are fixedly connected by keys, and one end of lever 7 is connected with Fork 8 is hingedly connected, and the other end of fork 8 is hingedly connected with the shaft of flashboard 2 . The above-mentioned two hinges are equipped with self-lubricating bushings 10 . The drive device 4 is arranged on the valve cover 3 . A section of guide block 11 for rotating opening and closing is respectively provided on both sides of the flashboard 2, and a slideway 9 is correspondingly arranged on the valve body. The flashboard 2 and the guide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com