Novel method for measuring liquid level by combining laser interference technology and free-state floater

A technology of laser interference and technical measurement, which is used in the field of high-precision measurement of medium liquid level in containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

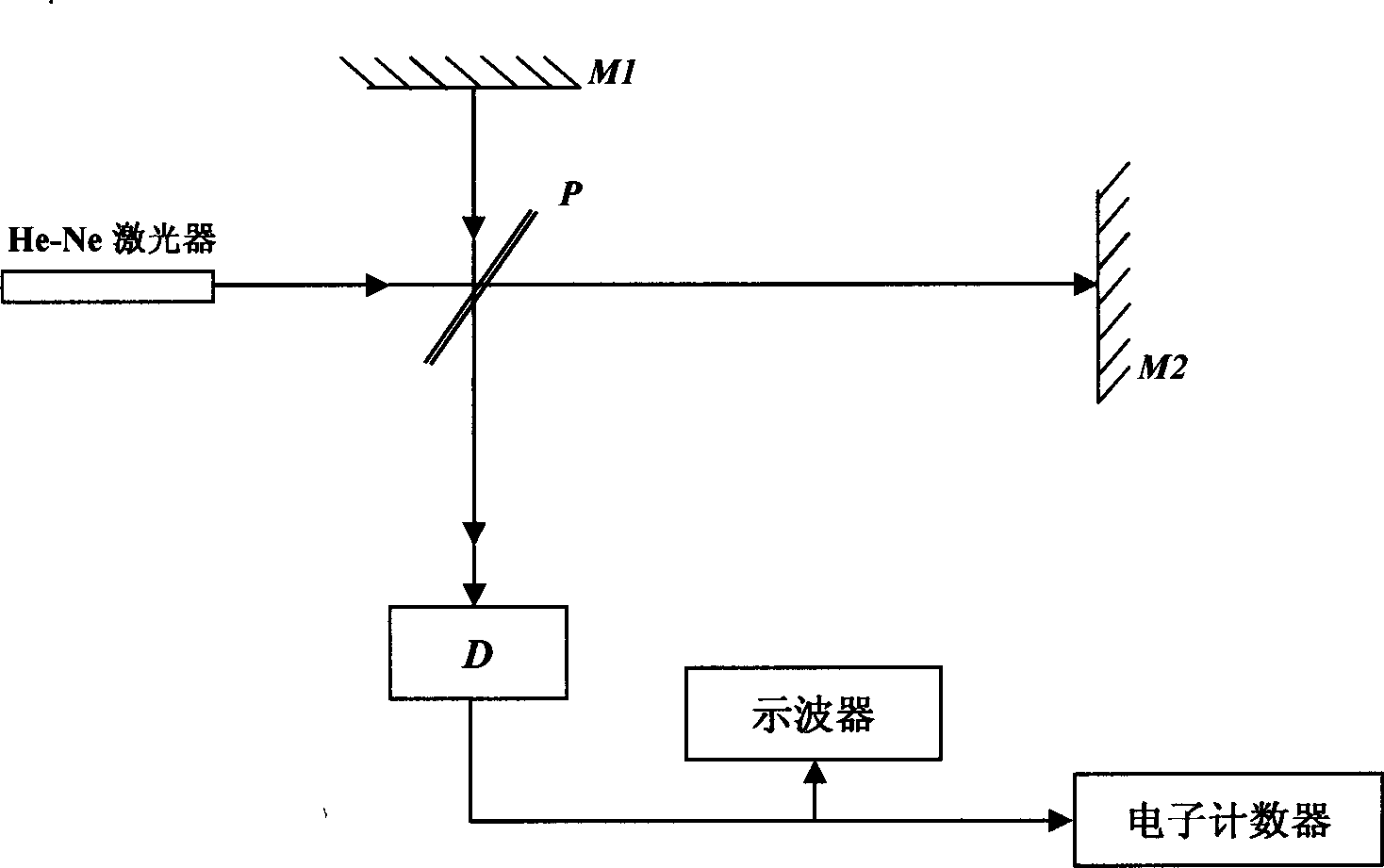

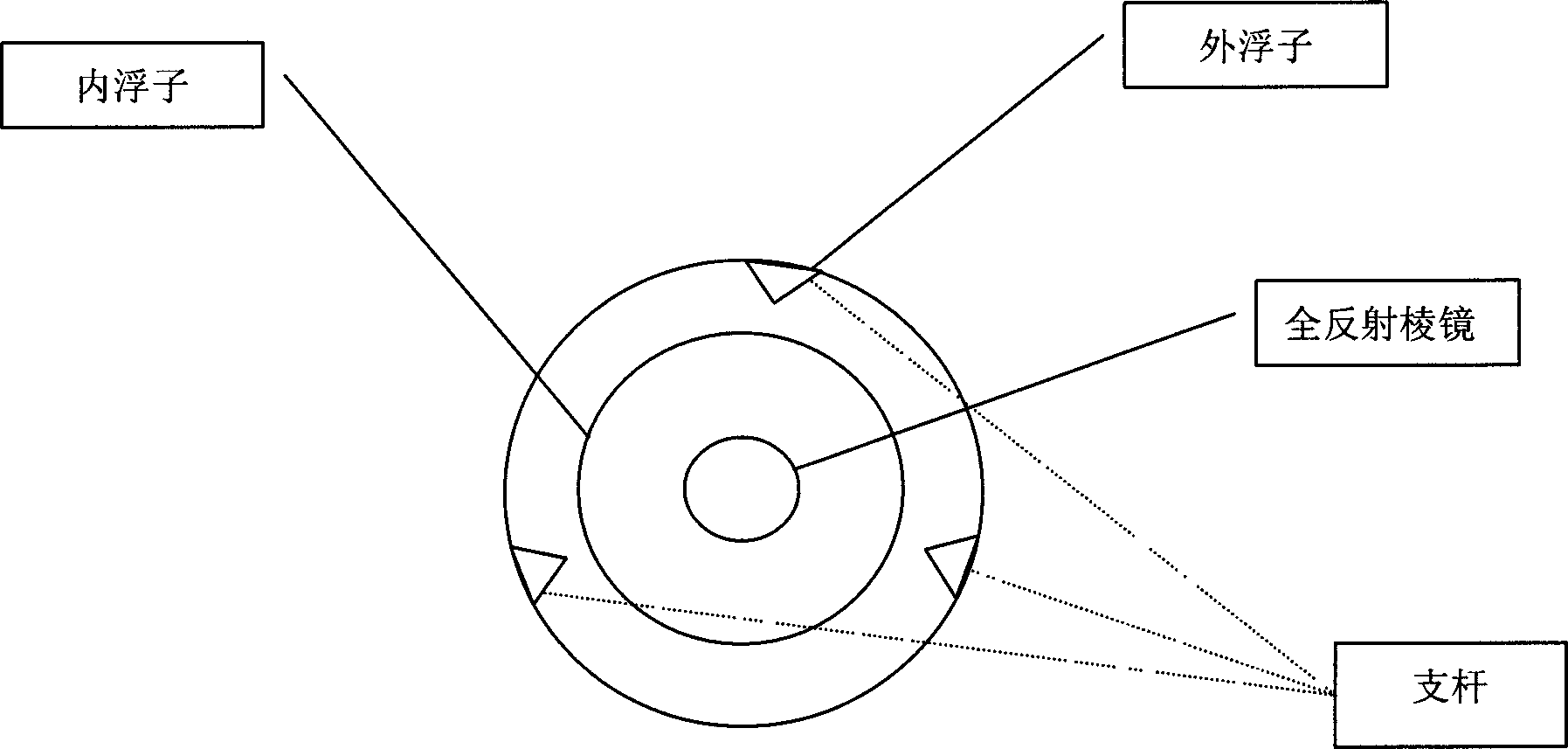

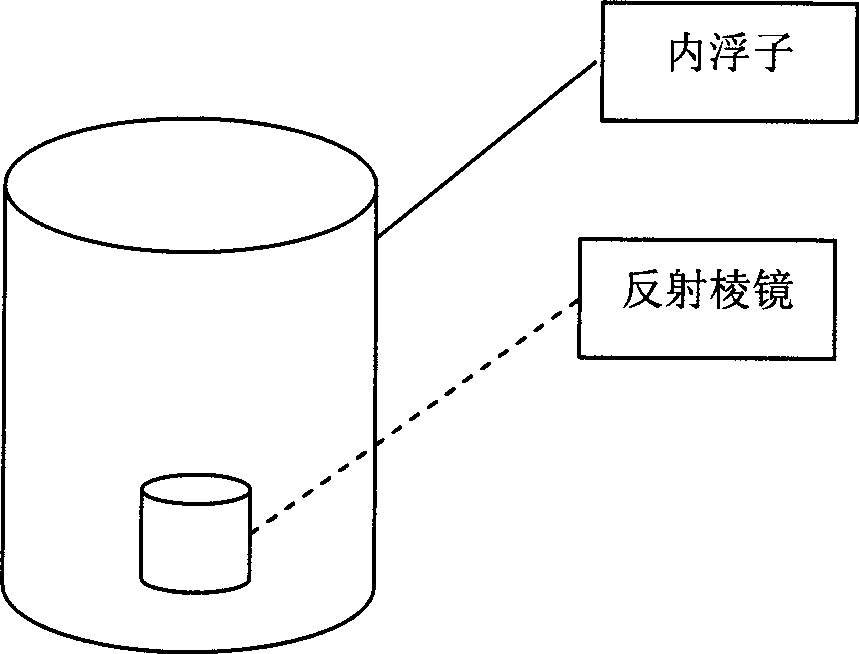

[0024] According to the method of the present invention, such as Figure 4 The device shown is tested. The container adopts a general vertical metal storage tank. The liquid level measuring device based on the method of the present invention mainly includes a dual-frequency laser interferometer, a total reflection prism fixed on a free-state float, a temperature transmitter, a pressure transmitter, and a humidity measuring instrument for correction of influencing factors, and The four components of the high-precision guide rail that restrain the free-state float to move in the vertical direction, the two ends of the high-precision guide rail are respectively fixed on the bottom plate and the top plate of the storage tank.

[0025] First, install the laser interferometer vertically on the top of the storage tank to ensure that the laser beam emitted by the laser can directly enter the storage tank. The laser beam is reflected by the total reflection prism fixed on the free-state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com