Composite hinge sheet for laser-marking multilayer laminate for electronic passport, laser-marking multilayer laminate for electronic passport, and electronic passport

A technology of laser marking and multi-layer sheets, which is applied in the directions of information-carrying cards, layered products, transportation and packaging, etc. It can solve the problems of large expectations and achieve the effects of excellent anti-counterfeiting, improved transparency, and anti-tampering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

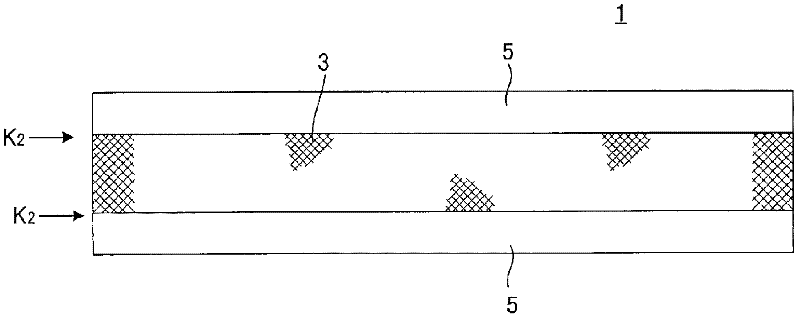

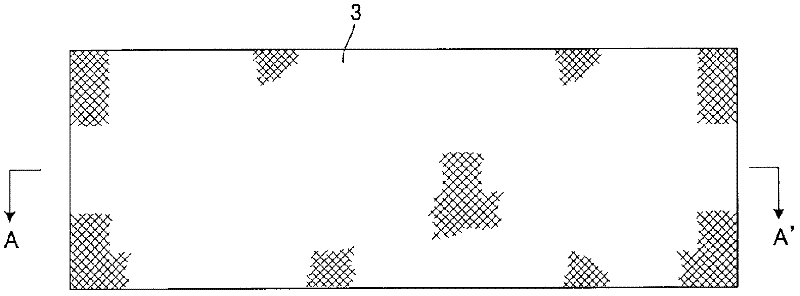

[0340] (Example 1) Composite hinged sheet [1]:

[0341] As a thermoplastic polyurethane elastomer (TPU), a non-yellowing type "Miractran XN-2004" manufactured by Japan Miractran Co., Ltd., with a hardness (Shore hardness A (hereinafter, also referred to as "Shore-A") as appropriate) of 95 was used. The polyester fabric (hereinafter, also referred to as "PET-mesh" or "PET-mesh cloth" as appropriate) used monofilament polyester "TNo-80-48" manufactured by Nippon Special Textile Co., Ltd., with a wire diameter of 48 μm and a thickness of 80 μm. The opening ratio is 72%. Next, TPU is melt-extruded from the T-die extruder at 185°C, and rolled with PET-mesh at the T-die outlet to form a TPU composed of TPU / PET-mesh A TPU / PET-mesh composite hinged sheet that is fully integrated with PET-mesh and forms a TPU skin layer on both sides of PET-mesh with a total thickness of 150 μm.

Embodiment 2

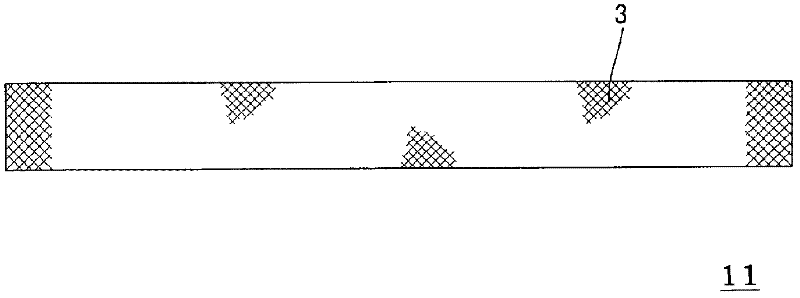

[0342] (Example 2) Composite hinged sheet [2]:

[0343] Use the same TPU and PET-mesh as in Example 1. In addition, in the same manner as in Example 1, two extruders with a T-die were used to melt and extrude TPU from the T-die extruder at 185° C., and immediately after the T-die exit, the TPU The composition of / PET-mesh / TPU is rolled and pressed to form a TPU / PET-mesh composite hinged sheet with a total thickness of 150 μm that is completely integrated with TPU and PET-mesh.

Embodiment 3

[0344] (Example 3) Composite hinged sheet [3]:

[0345] Instead of the PET-mesh of Example 1, a fabric of thermoplastic polyamide (hereinafter also referred to as "polyamide-mesh" as appropriate), a monofilament polyamide "NNo-100M" manufactured by Nippon Special Fabrics Co., Ltd., with a wire diameter of 71 μm, Thickness 125μm, aperture ratio 52%. Except for this, in the same manner as in Example 1, a fully integrated TPU / polyamide-mesh composite hinge sheet with a total thickness of 150 μm consisting of TPU / polyamide-mesh was formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com