Motor vehicle lock

A technology of latching and rotating latches, which can be used in vehicle locks, building locks, lock applications, etc., and can solve problems such as small stability and reduced mechanical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

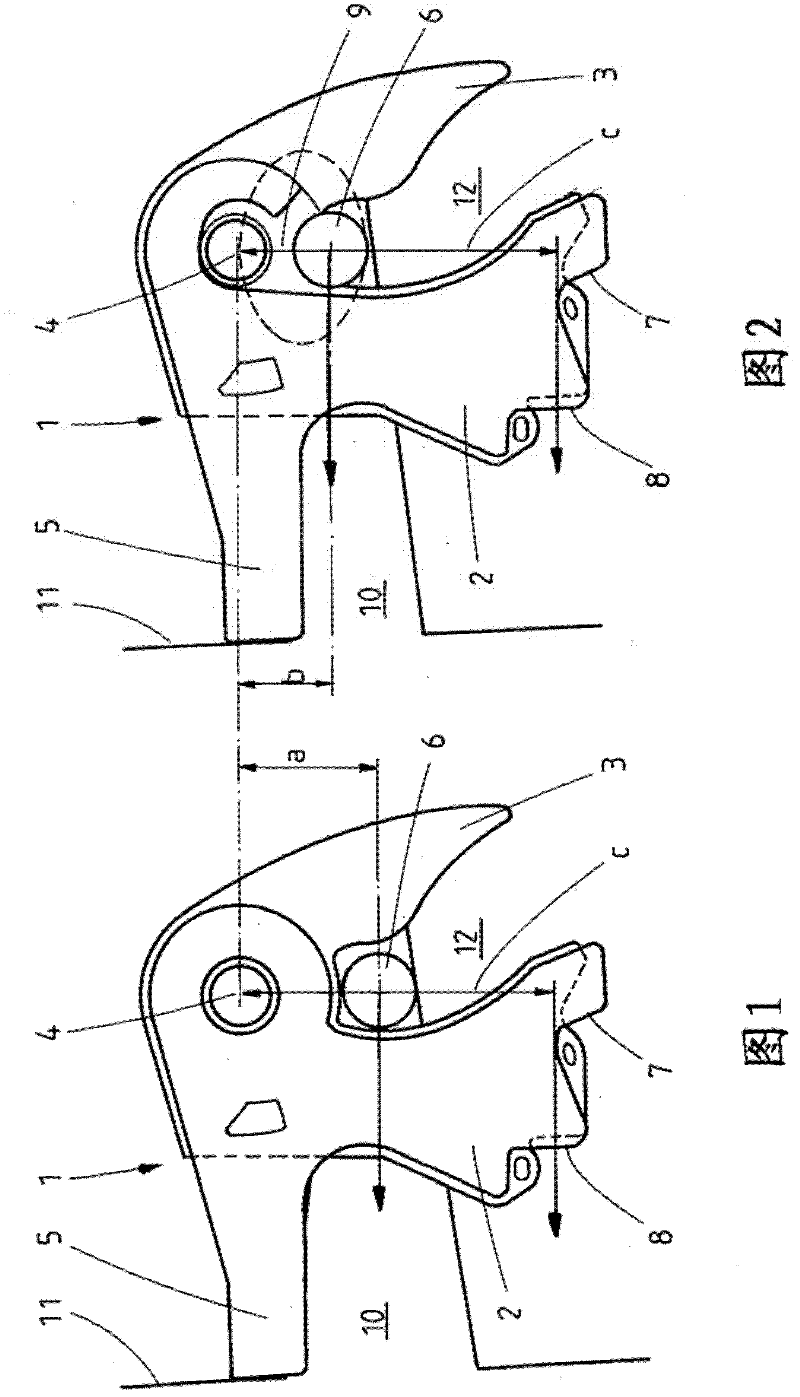

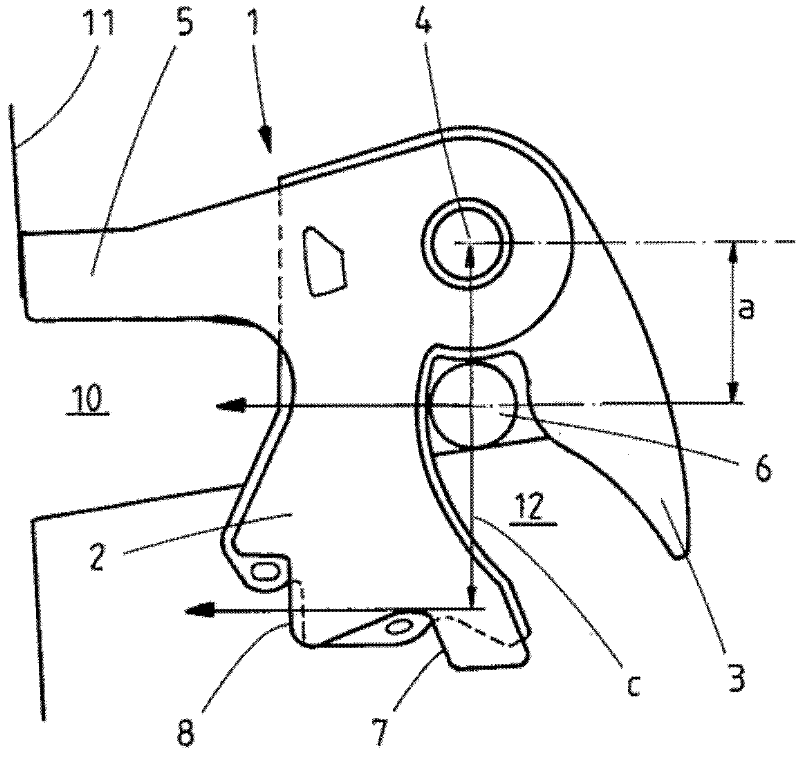

[0029] figure 1 with 2 The top view showing the locking mechanism in the main locking position, it has a rotary latch 1, the rotary latch includes a load arm 2 and a catch arm 3, and the rotary latch is rotatably supported by the rotary latch shaft 4. The load arm 2 prevents the lock pin 6 from leaving the entrance slot 10 of the lock box. The locking pawl required for locking in the main locking portion 8 is not shown for the sake of clarity.

[0030] As compared figure 1 with 2 As clearly seen, in the embodiment according to the present invention ( figure 2 ) Chinese and traditional structure ( figure 1 Compared with ), the distance between the rotary latch shaft 4 and the lock pin 6 is significantly reduced. And in accordance with figure 1 The traditional embodiment shown is different, in figure 2 In the embodiment according to the invention shown in there is a relatively narrow tab 9 made of plastic, which separates the rotary latch shaft 4 from the lock pin 6 in the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com