Device using multichannel chute to transport materials in group and having speed reducing function

A multi-channel, chute technology, applied in the direction of chute, transportation and packaging, etc., can solve the problems of uncontrollable material sliding speed, inability to ensure material integrity, material damage, etc., to achieve the elimination of safety hazards, simple structure and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

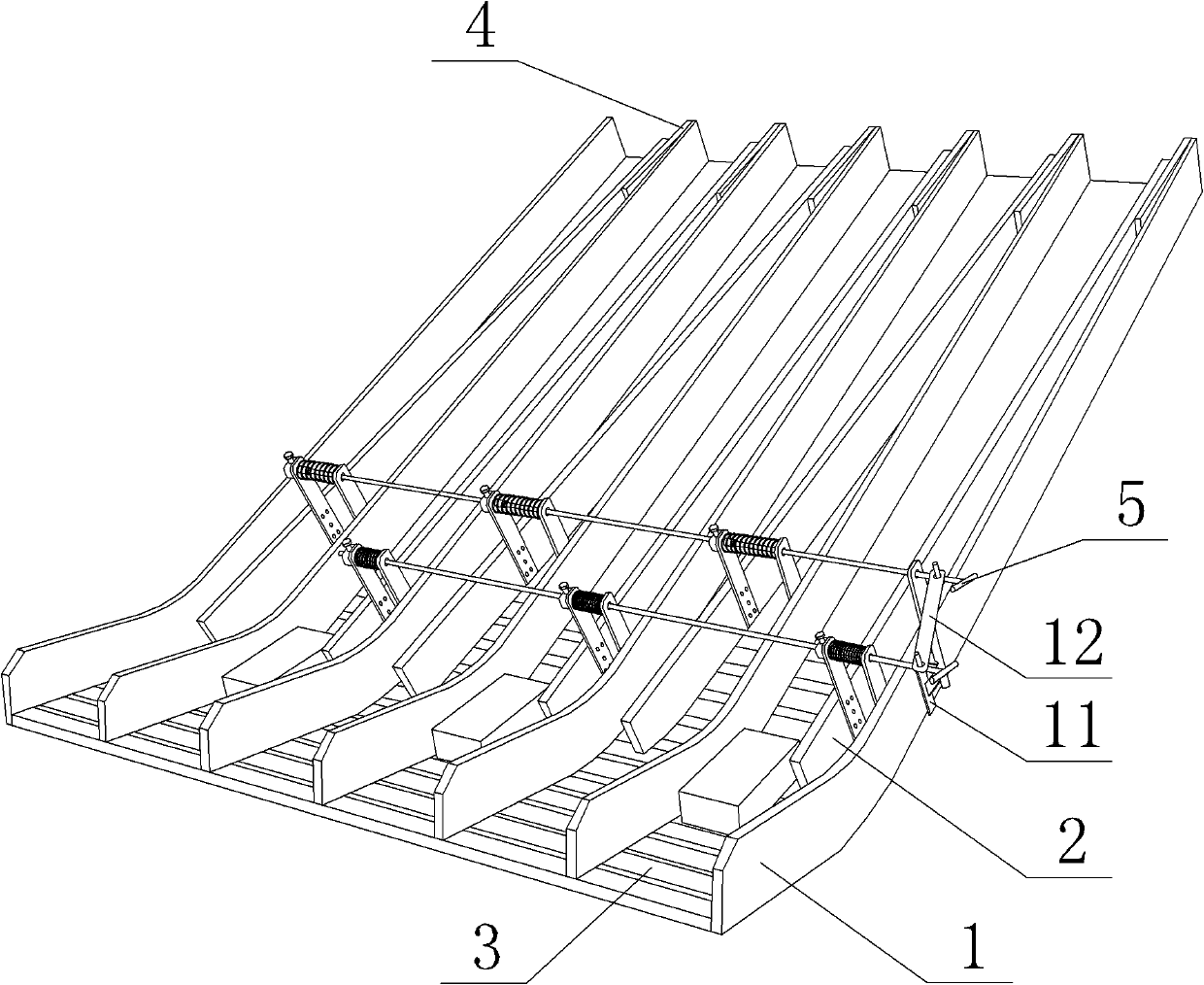

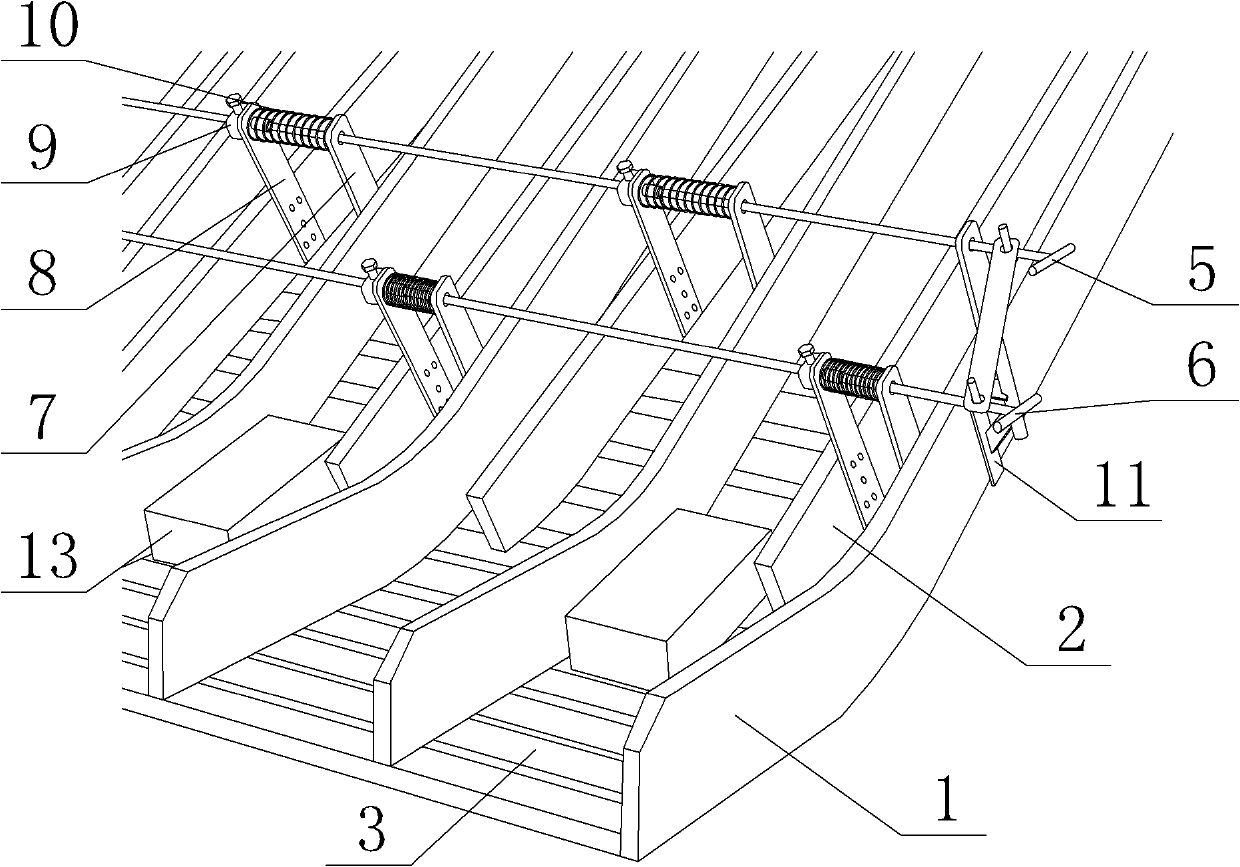

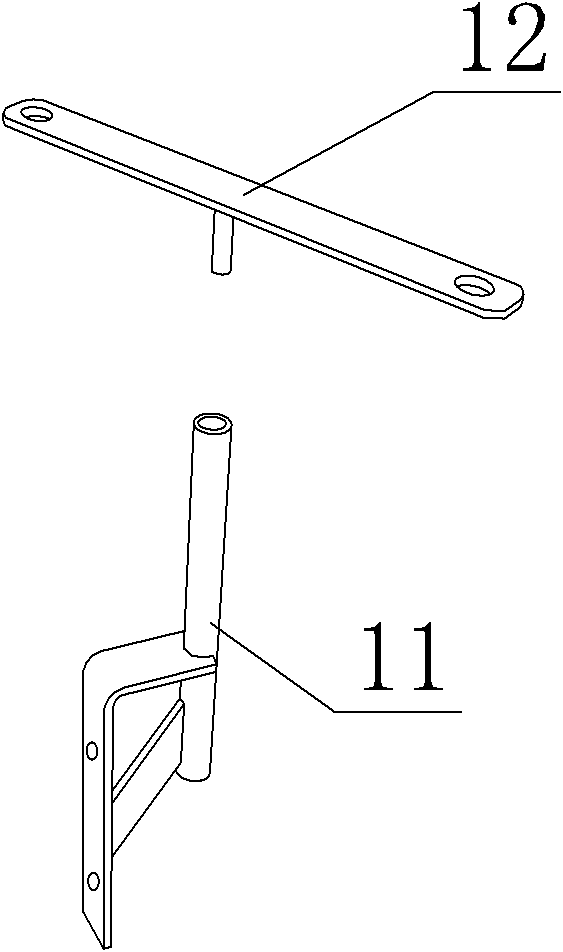

[0021] see Figure 1 to Figure 5 , a multi-channel chute device for group blanking with deceleration function, which includes a chute main body 1, an oblique deceleration plate 2, a first telescopic control mechanism, a second telescopic control mechanism, and a horizontal deceleration plate 3; the chute of multiple channels Main body 1 is made up of bottom plate and 3-21 side plates (that is, 2-20 passages), and 3-21 side plates are positioned on the bottom plate and are fixed with the bottom plate, and the chute channel is formed between adjacent side plates (this embodiment 6 chute channels are used, the specific number is determined according to the needs; the width of the chute channel is determined by the size of the material to be transported), the main body of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com