Synchronous packaging box discharging buffering device used for filling machine

A buffer device and filling machine technology, which is applied in packaging and other directions, can solve the problems of rollover of the packaging channel, lower production efficiency, blockage, etc., and achieve the effect of good neutrality and not easy to rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

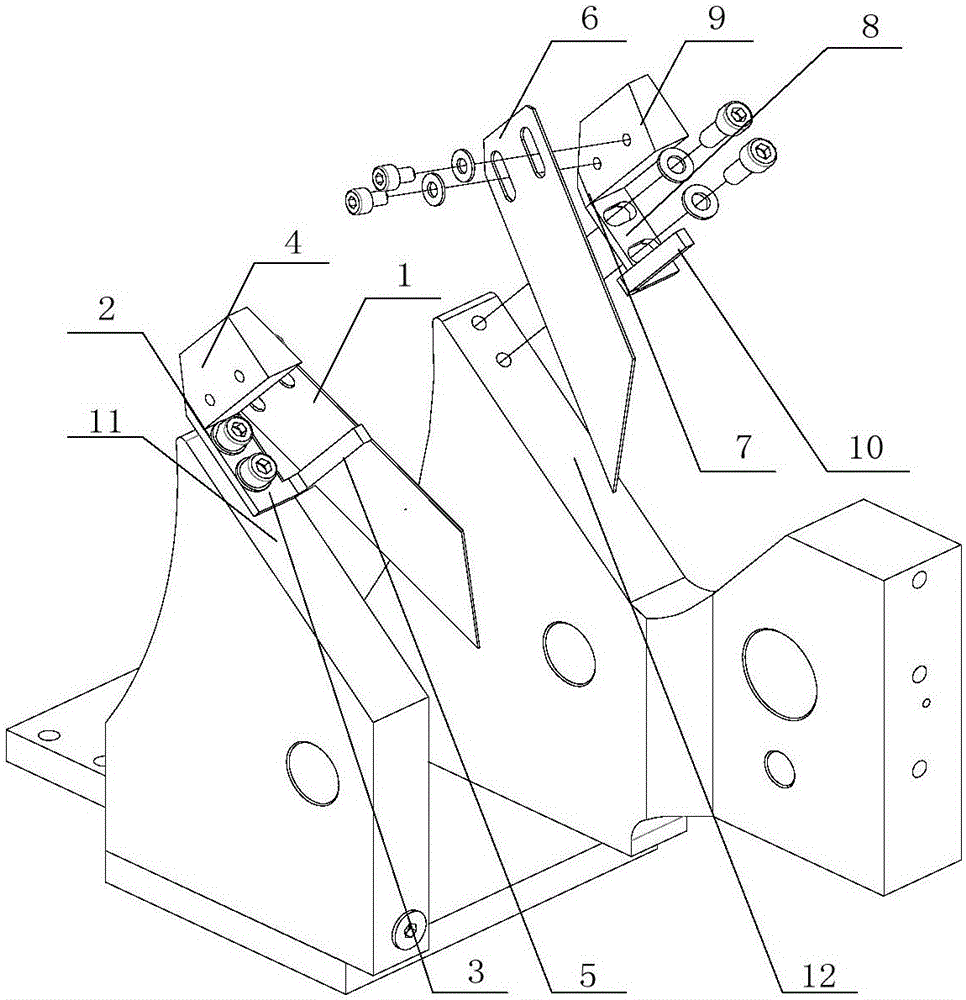

[0043] The packaging synchronous buffer device for filling machines described in this embodiment is used to reliably and stably transfer the formed packaging boxes to the conveyor chain. The filling machine includes a Packing devices, such as Figure 7 As shown, the described packaging device includes a driving disc 25 and a package output channel for the packaging box to slide down. The drive disc 25 is arranged in pairs between the terminal of the station chain and the package output channel. The paired A conveying device for transporting the packaging box is provided between the drive discs 25, preferably, in this embodiment, a slide plate is used.

[0044] The said package-discharging synchronous buffering device includes elastic devices, which are respectively installed on the two vertical walls of the package-discharging channel of the package-discharging device. It plays the role of buffering the speed of the packaging box.

[0045] Preferably, the elastic device is s...

Embodiment 2

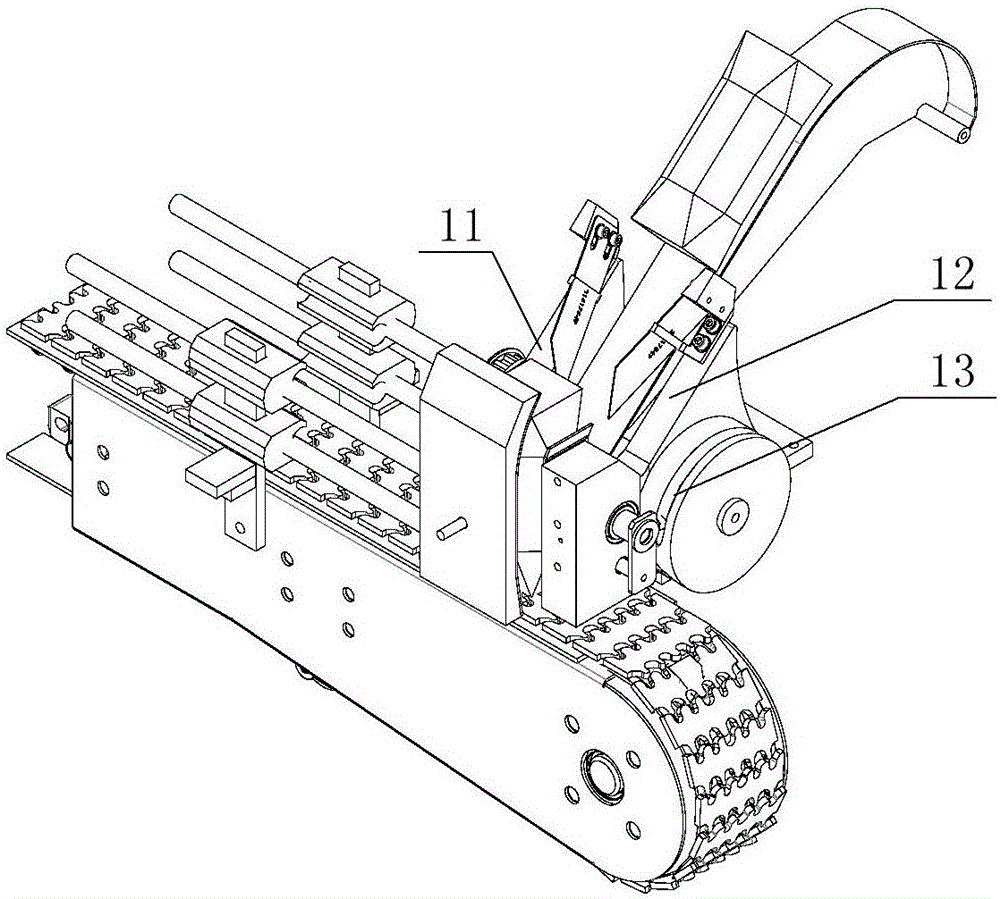

[0067] Such as figure 2 As shown, in this embodiment, on the basis of the above-mentioned embodiments, in order to transmit the packaging box to the conveyor chain more stably, a synchronous package pushing device is provided on the second vertical wall 12 of the package discharge channel of the package discharge device. The package-discharging synchronous pushing device includes a driving component and a package-pushing component, and the pushing-pack component is arranged between the package-discharging device outlet channel and the conveying chain; the driving component is used to drive the pushing-pack component to reciprocate; the packaging When the box is at the out-packing position, the driving assembly drives the pushing-pack assembly to move along the transmission direction of the conveying chain and pushes the packing box to the conveying chain; when the packing box is away from the out-packing position, the driving assembly drives the pushing-packing The chain driv...

Embodiment 3

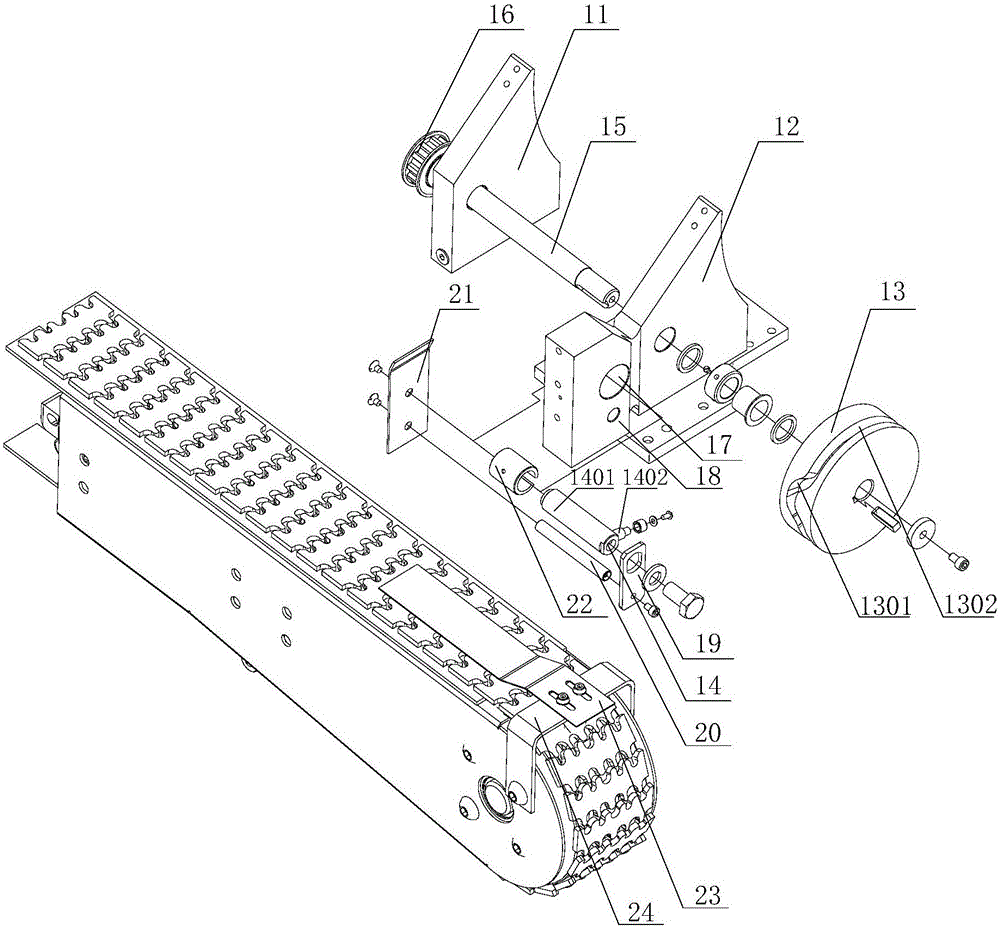

[0087] Such as Figure 6 As shown, the difference between this embodiment and the above-mentioned embodiments is that a transition device is provided on the base of the conveyor chain, and the transition device includes a transition plate 23 and a transition plate bracket 24, and the transition plate 23 can be adjusted to be installed on the transition On the plate support 24, the transition plate support 24 is fixed on the base of the conveyor chain.

[0088] The transition plate 23 is rectangular, and the transition plate 23 is provided with a strip hole, and the fixed position of the transition plate 23 can be adjusted through the strip hole; the transition plate 23 is parallel to the conveying chain, and when the packing box slides, it just falls on the on the transition plate 23.

[0089] The transition board bracket 24 is U-shaped, and the transition board bracket 24 is provided with mounting holes for fixing the transition board 23; the two ends of the transition board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com