Skip car slow descending device and control method

A material truck and slow-down technology, applied in auxiliary devices, manufacturing tools, transportation and packaging, etc., can solve the problems of laborious return to the ground, prone to safety accidents, etc., and achieve the elimination of safety hazards, stable clamping effect, and low maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0056] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0057]In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and "fixation" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection , or integrated; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components or the interaction relationship between two components, unless otherwise specified limit. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

[0058] In the present in...

Embodiment 1

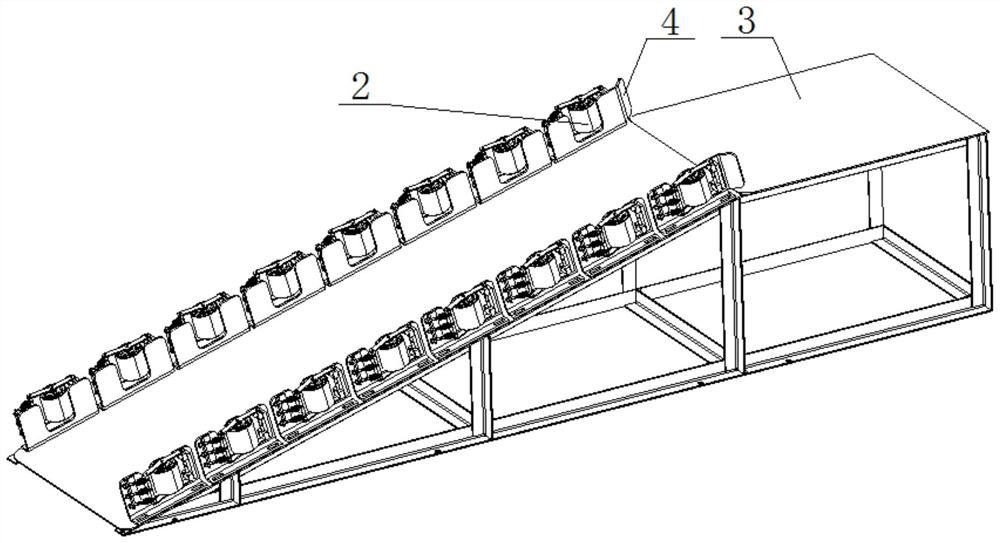

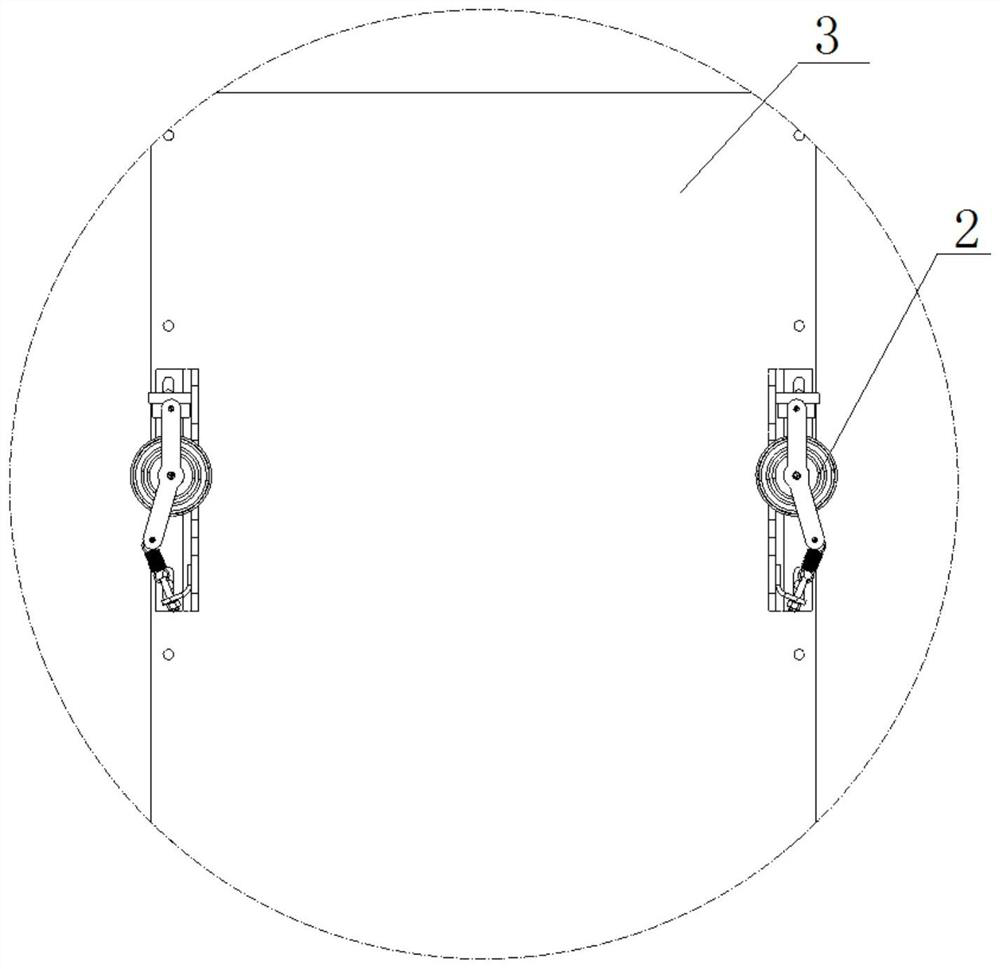

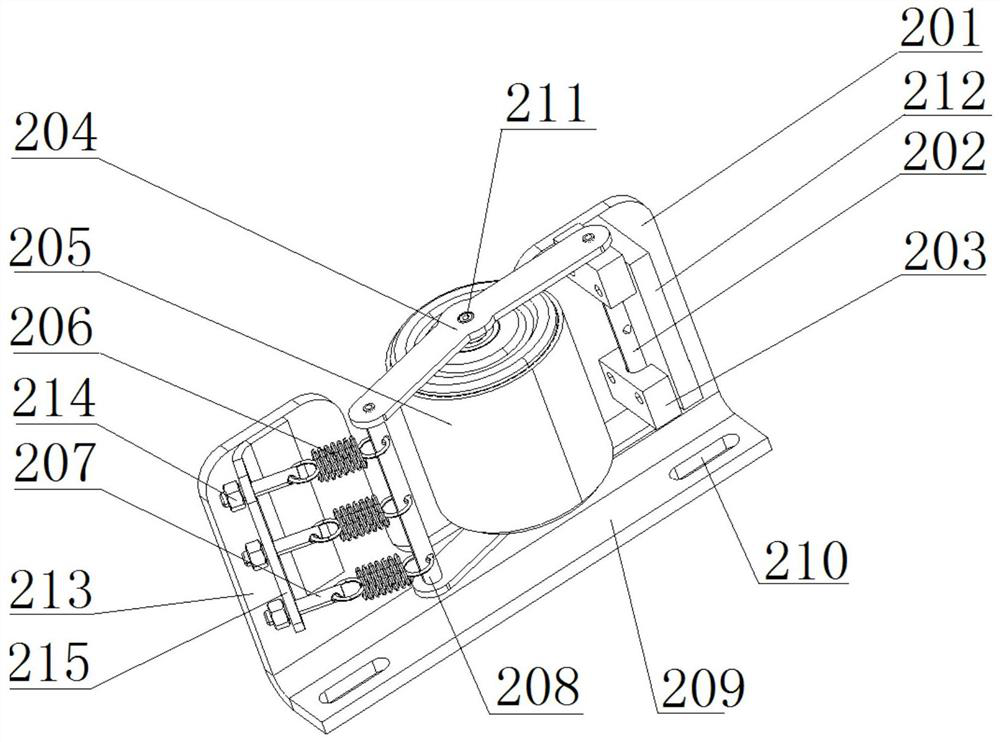

[0061] This embodiment 1 discloses a slow-down device for a material truck, such as figure 1 As shown, the slow-down device for the material truck includes: a spring roller mechanism 2, a step slope mechanism 3 and a guide plate 4; wherein, the spring roller mechanism 2 is evenly distributed in pairs along both sides of the slope surface of the step slope mechanism 3 , the guide plate 4 is arranged at the position where the slope surface of the step slope mechanism 3 intersects with the top step surface.

[0062] Such as figure 2 As shown, in the first embodiment, the spring roller mechanism 2 located on the same side of the slope surface of the step slope mechanism 3 has the same structure and size, and is linearly distributed, and the spring roller mechanisms 2 on both sides of the step slope mechanism 3 slope surface are symmetrical distributed in groups, and the distance between the same group of spring roller mechanisms 2 on both sides of the slope surface of the slope ...

Embodiment 2

[0083] The second embodiment discloses a method for controlling the slow down of the feed truck, such as Figure 5 As shown, the slow-down control method of the material truck adopts the slow-down device of the material vehicle described in the first embodiment, and the specific control process is as follows:

[0084] Step S1: The side wall material truck 1 is sent to the entrance of the material truck slow down channel between the step surface 303 and the slope surface 302 of the step slope mechanism 3 under the operation of the worker;

[0085] Step S2: After pushing the side wall trolley 1 along the guide plate 4 into the slow-down passage of the trolley formed between the spring roller mechanisms 2 arranged in groups on both sides of the slope surface 302, make the side wall trolley 1 under its own gravity Under the action, move down along the slope surface 302, and under the clamping action of the spring roller mechanism 2 on both sides, move down smoothly and slowly alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com