Secondary forming baking and bending die of automobile glass

A secondary molding and automotive glass technology, applied in glass molding, glass reshaping, glass production, etc., can solve the problems of time-consuming and labor-intensive reset operations, and cannot be reset at the same time, so as to avoid mold deformation, increase production efficiency, and save energy. The effect of the timing of the reset operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be further described below in conjunction with the accompanying drawings.

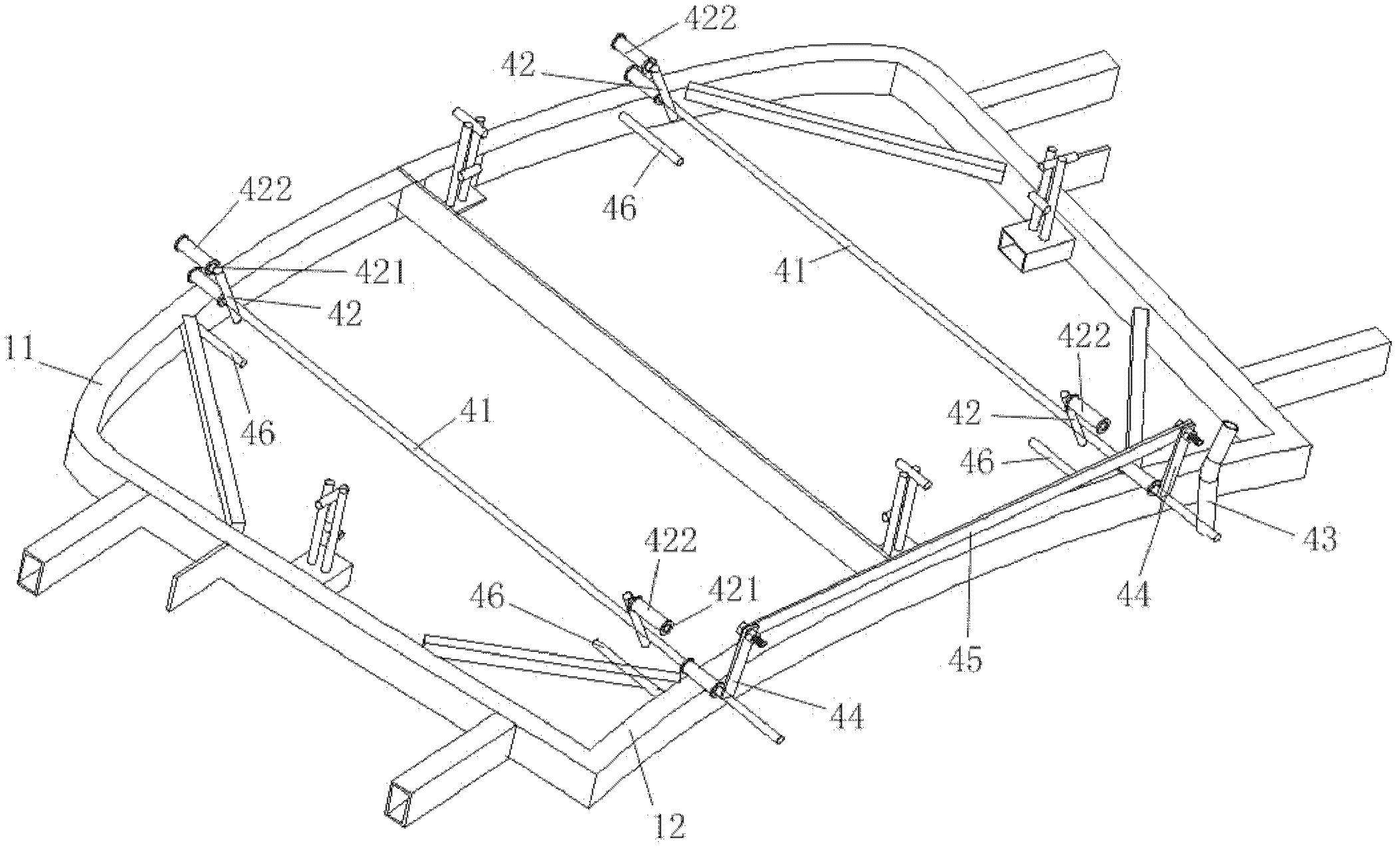

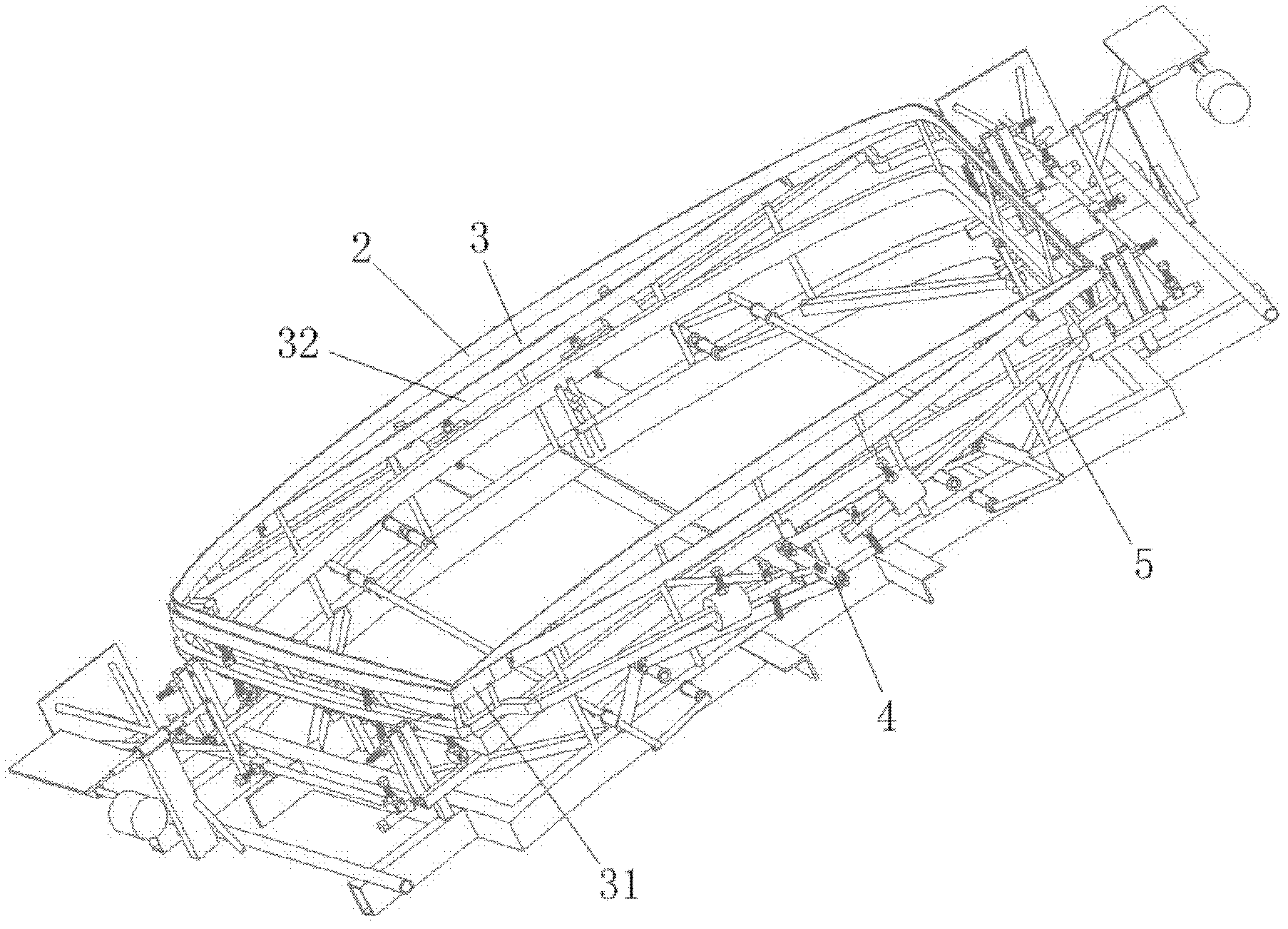

[0025] In actual production, the glass plate that is generally subjected to secondary baking and bending has four sides, of which there is a pair of sides that are symmetrical in the center and equal in length; among the other pair of sides, the relatively long one is called the "big head side", and the relatively short one is called the "big head side". Known as the "small head edge", the molds used for post-bending this type of glass sheet also have a roughly similar shape. Similarly, the side on the mold corresponding to the "big side" of the supporting glass plate is also called the big side, and the side corresponding to the "small side" of the supporting glass plate is called the small side.

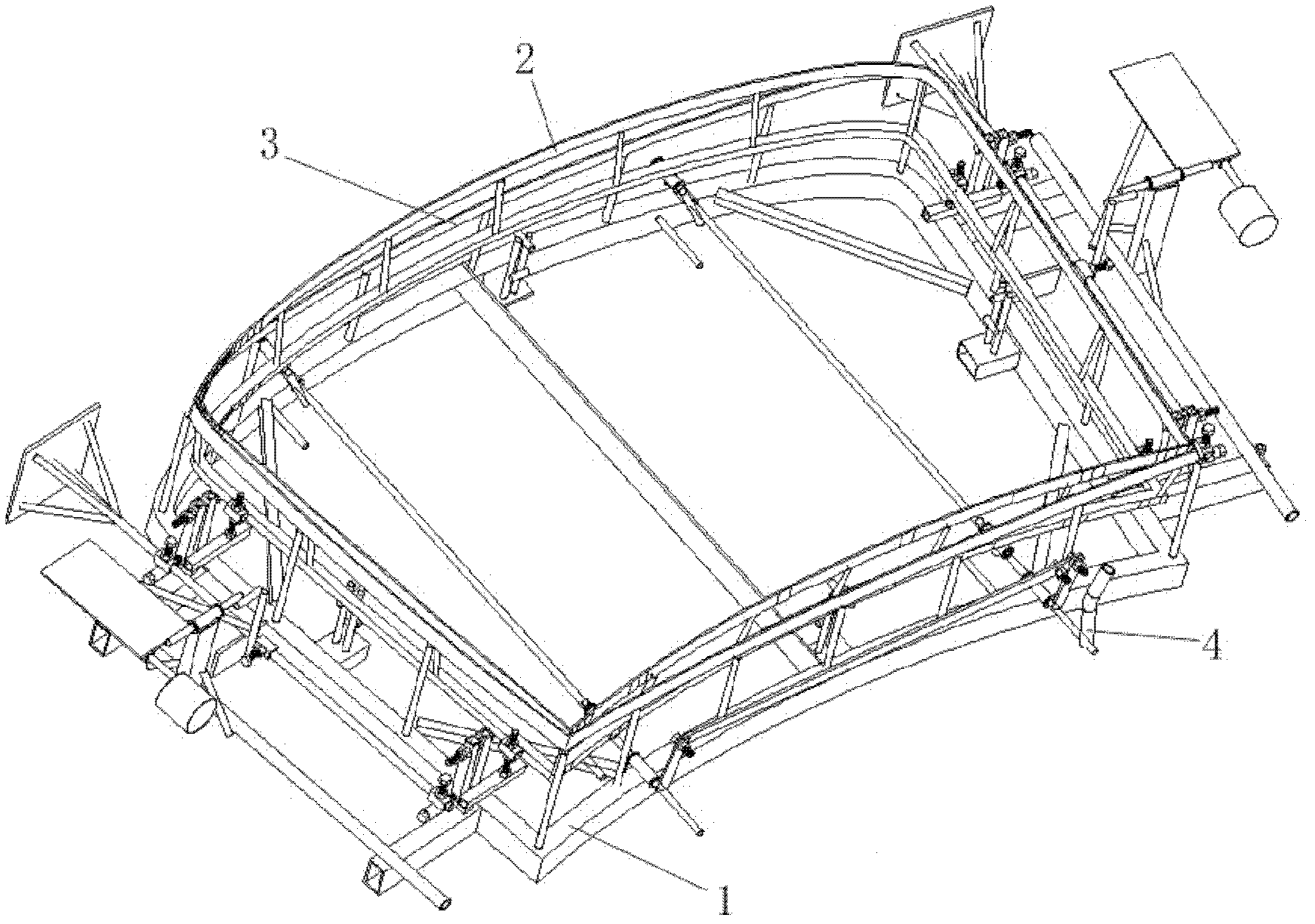

[0026] Such as figure 1 Shown in the first embodiment of the present invention, the automotive glass secondary molding baking mold shown in it includes a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com