Method of gas recovery by water drainage for high-coal-rank coal-bed methane well

A technology for coalbed methane wells and coal rank, which is applied to the field of drainage and gas production of high coal rank coalbed methane wells, can solve the problems of low coalbed permeability, rapid decline in production, low well gas production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Well Gu 02 adopts the method of drainage and gas recovery of high coal-rank coalbed methane wells to produce gas, and further details the present invention.

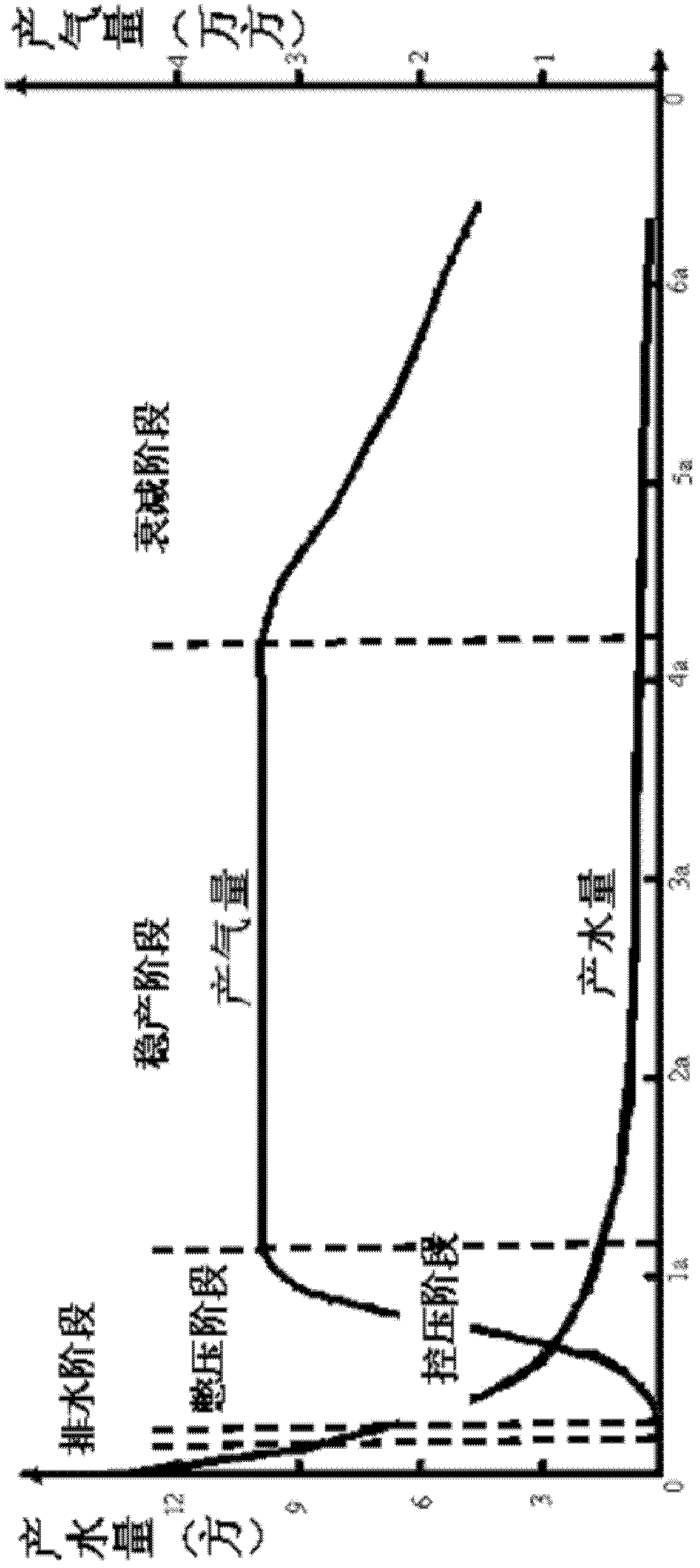

[0020] refer to figure 1 . The method of drainage and gas production of high coal-rank coalbed methane wells includes drainage stage, pressure holding stage, pressure control stage, stable and high production stage and decay stage, and different stages have different pressure controls.

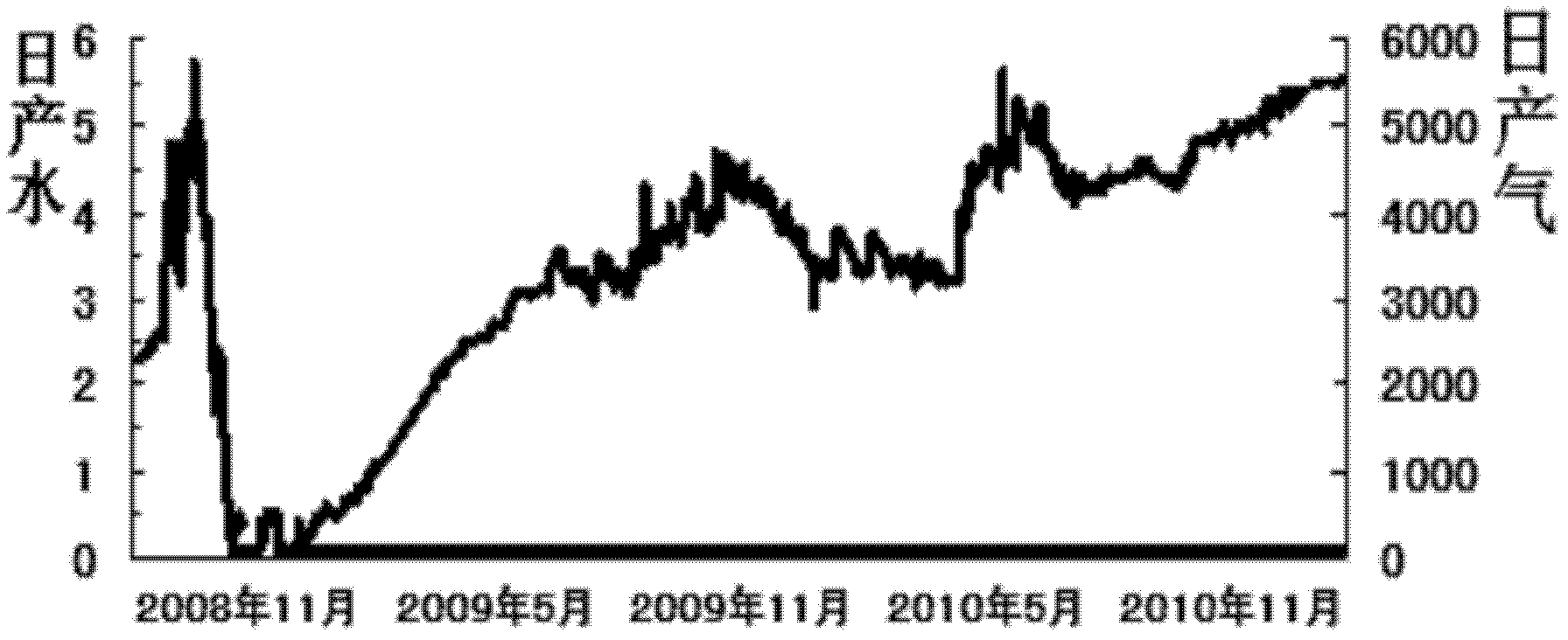

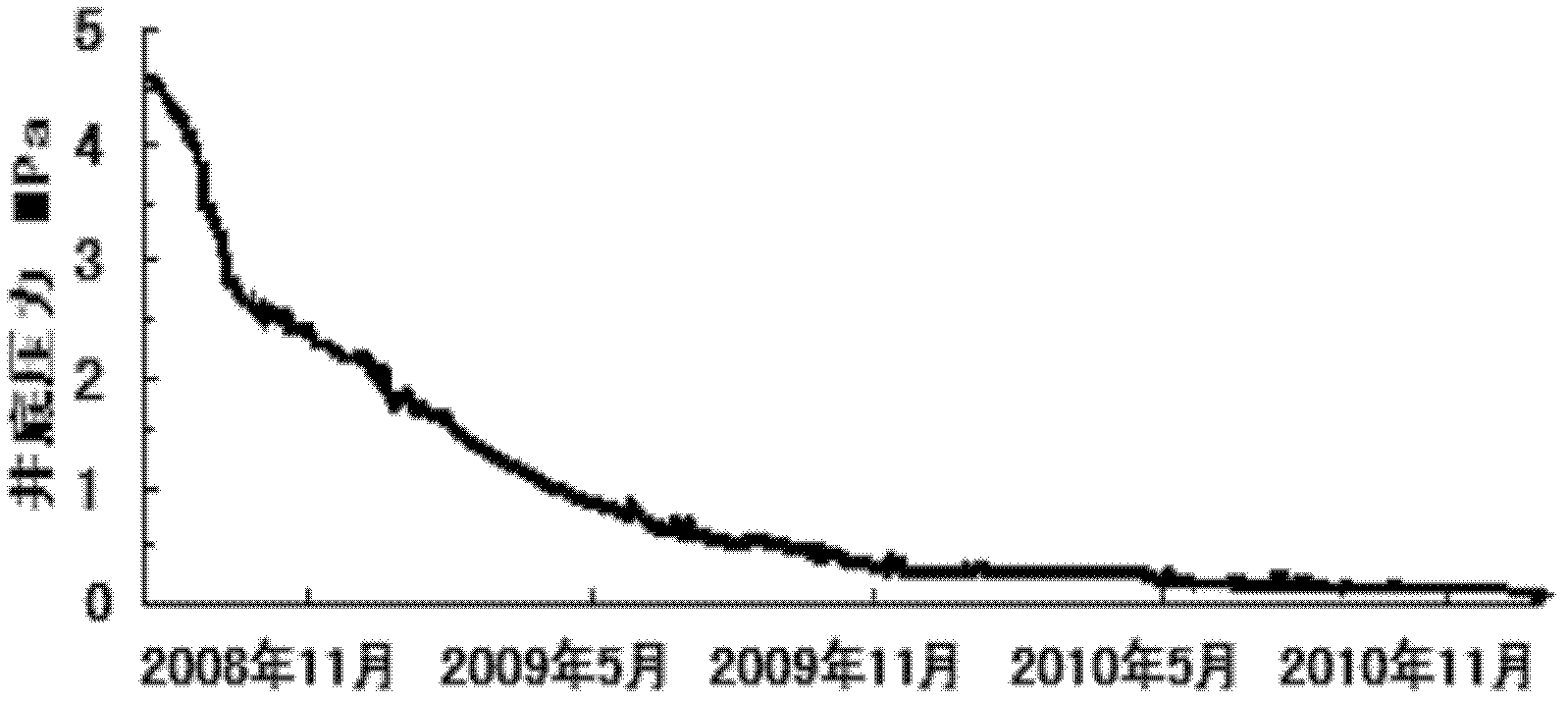

[0021] refer to figure 2 and image 3 .

[0022] Step 1. Drainage stage: Drainage starts from well Gu02 until the bottom hole pressure is 3.8MPa; in the drainage stage, all the casing gates at the wellhead are closed, the tubing gate is opened for drainage, and the bottom hole pressure drop rate is controlled at 0.06MPa / d, monitored by a downhole pressure gauge; the falling speed of the dynamic liquid level is controlled at 6m / d. The control method adopts automatic control. When the pressure value of the slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com