Moving blade regulating device for axial flow fan

A technology of axial flow fan and regulating device, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., which can solve the problems of low control precision of the rotation angle of moving blades, and achieve simple and reliable operation , Rescue mine safety and ensure the effect of mine safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

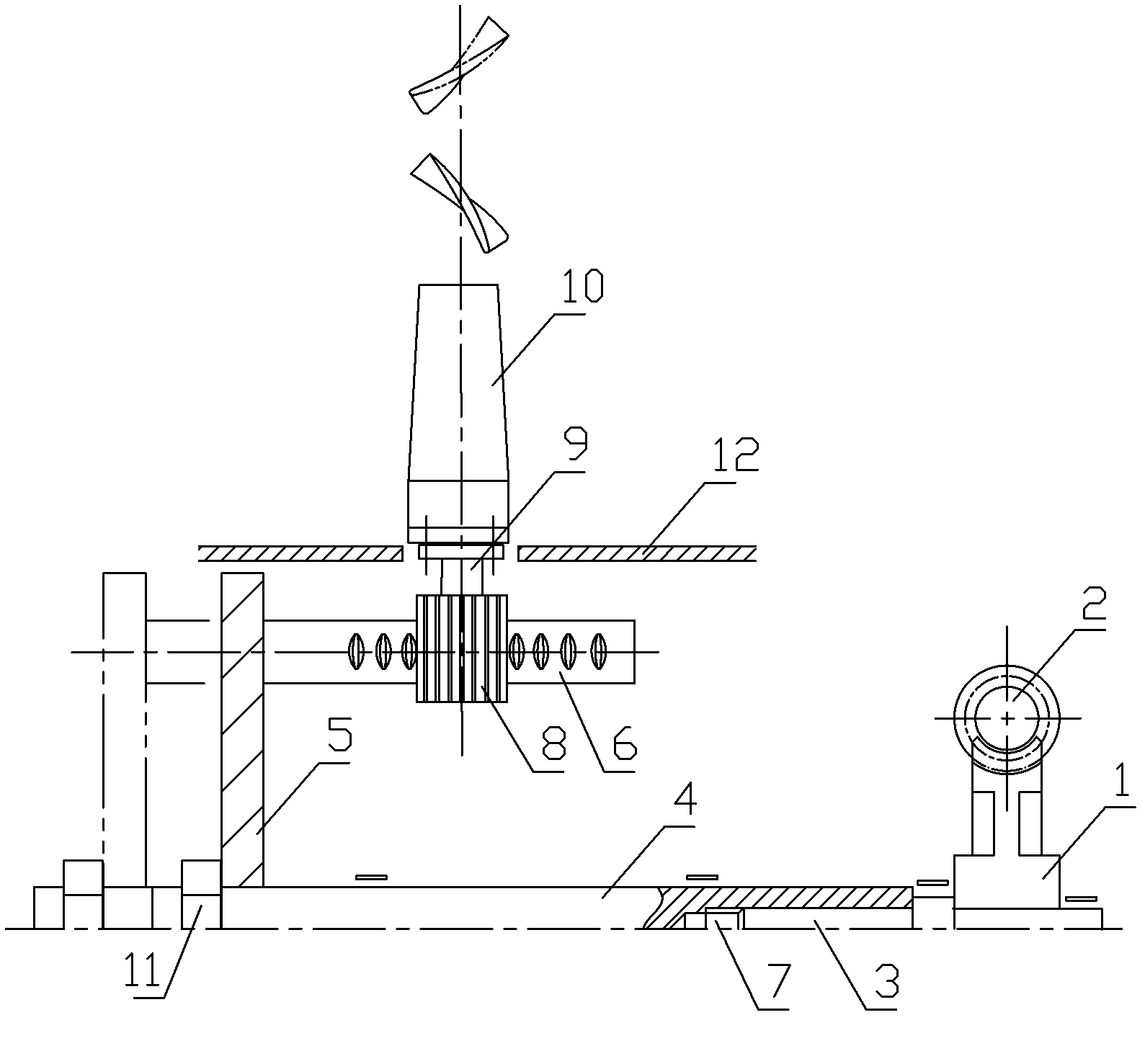

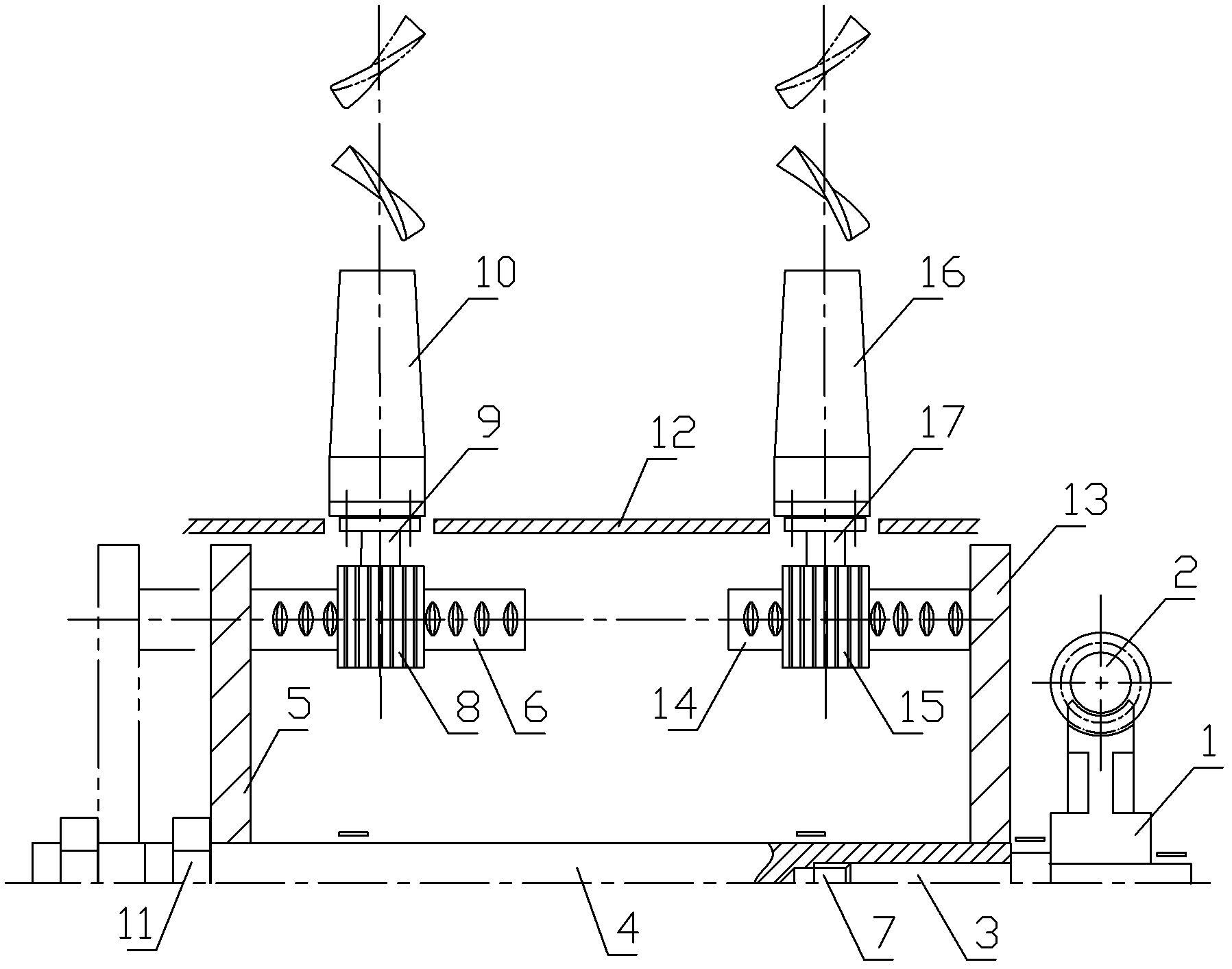

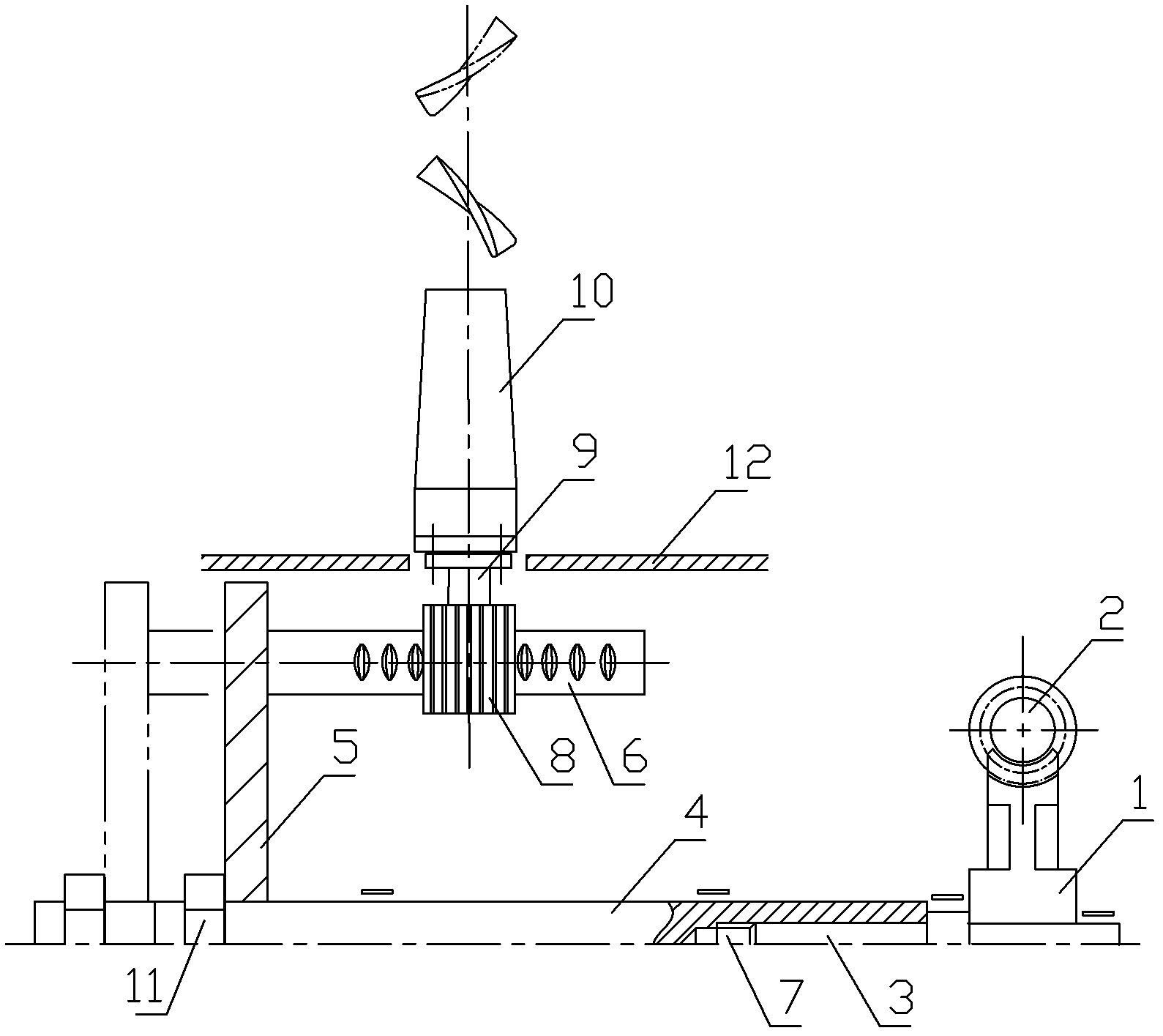

[0017] See figure 1 , is a structural schematic diagram of an embodiment of an axial flow ventilation rotor blade adjustment device according to the present invention. This is a single-stage fan rotor blade adjustment device, including a worm wheel 1, a worm screw 2, a lead screw 3, a nut shaft 4, a coupling disc 5 and a gear Bar 6, one end of the nut shaft 4 is coaxially connected with the coupling plate 5 through a nut 11, the other end of the nut shaft 4 is provided with a threaded hole 7 to connect with one end of the lead screw 3, the other end of the lead screw 3 is connected coaxially with the worm wheel 4, and the worm wheel 1 and The worms 2 mesh with each other, and the racks 6 are uniformly arranged on the side of the coupling disc 5. The number of racks 6 is consistent with the number of fan blades 10. The central circle where the rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com