Edge guide of curtain coater

An edge-guiding and curtain coating technology, which is applied to devices for coating liquid on surfaces, coatings, textiles, and papermaking, can solve problems such as edge turbulence, dry flow tracks, etc., and achieve stable coating and high-speed coating , the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

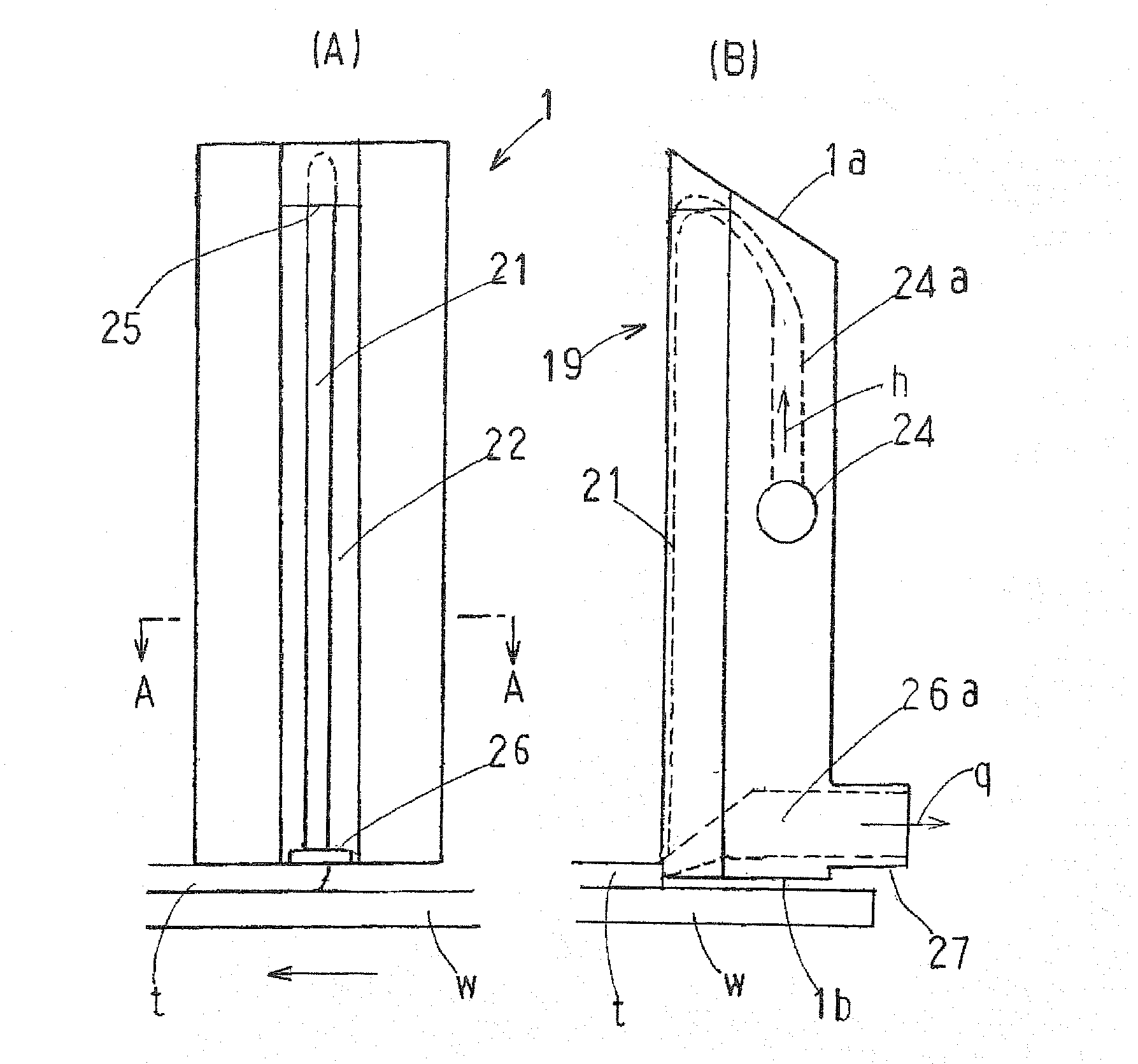

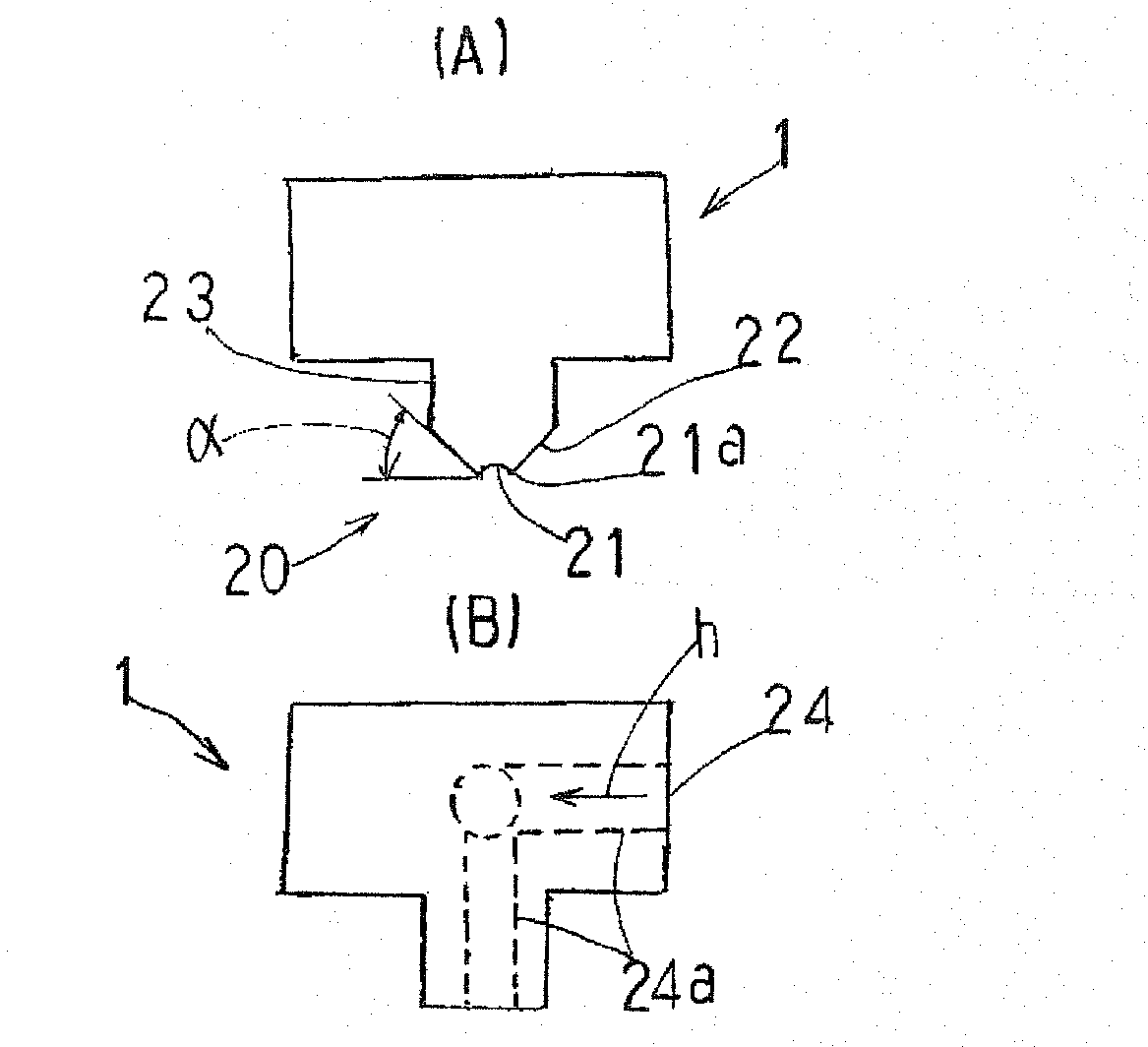

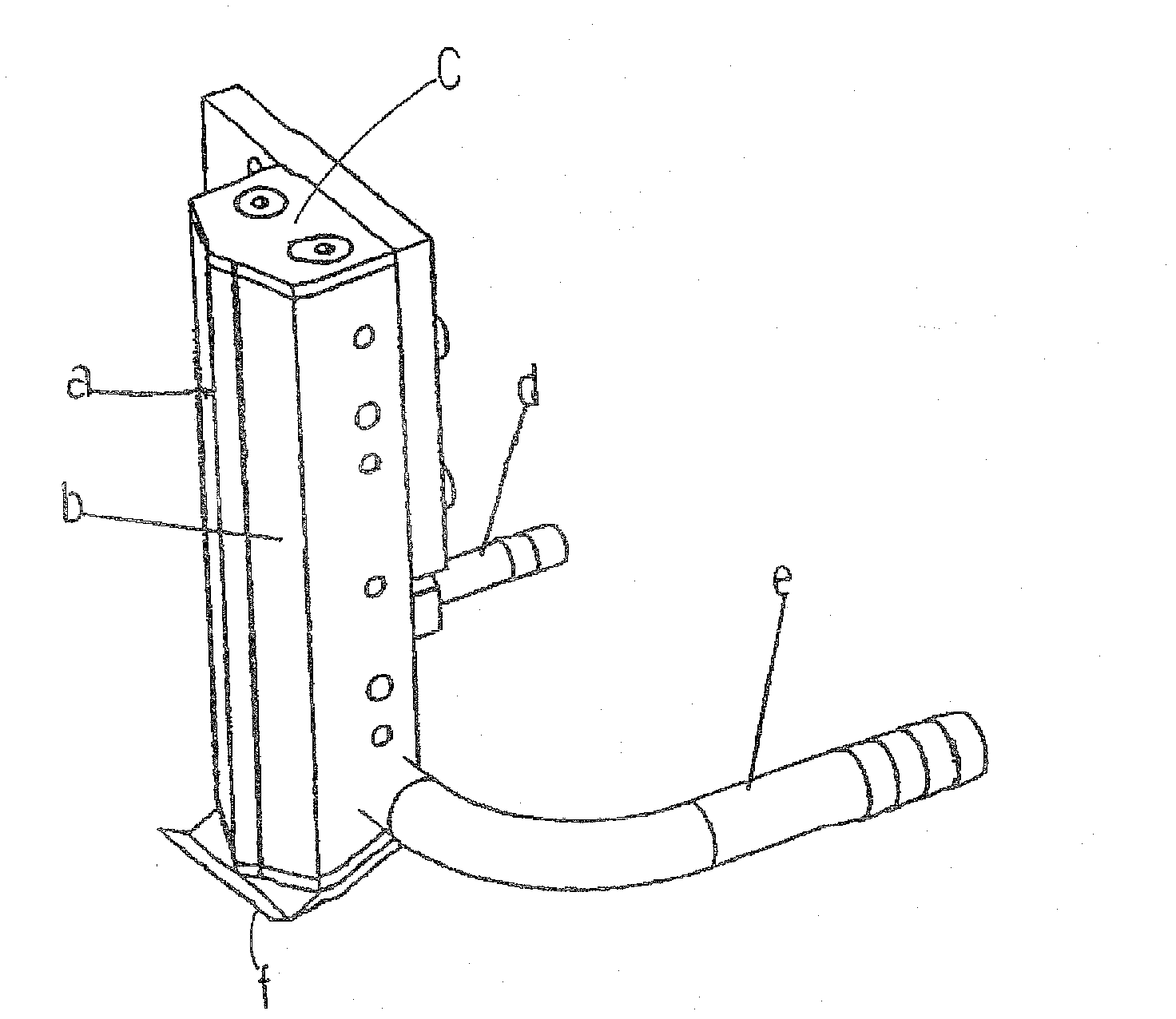

[0052] figure 1 It is drawing of the edge guide of the curtain coater of this invention, (A) is a front view seen from inside, (B) is a side view. figure 2 (A) is an A-A sectional view of an edge guide of a curtain coater, figure 2 (B) is a plan view. Figure 9 is a drawing showing the state where the edge guide is mounted on the guide plate, Figure 9 (A) is a diagram showing a state where the guide plate is cut inside the edge guide installation part, and is an explanatory diagram of the teapot phenomenon, Figure 9 (B) is a side view showing the state where the edge guide is attached to the guide plate. Figure 10 is a drawing showing the state where the edge guide is mounted on the mold, Figure 10 (A) means single layer coating, Figure 10 (B) represents two-layer coating using one mold, Figure 10 (C) shows two-layer coating using two dies. Figure 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com