Micro longitudinal cutting turning machine

A turning machine and slitting technology, applied in the field of multi-function machine tools, can solve the problems of high efficiency and high precision processing of micro and small rotary parts, and the failure to process micro and small rotary parts, and achieve high precision. The effect of machining, increasing cutting speed and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

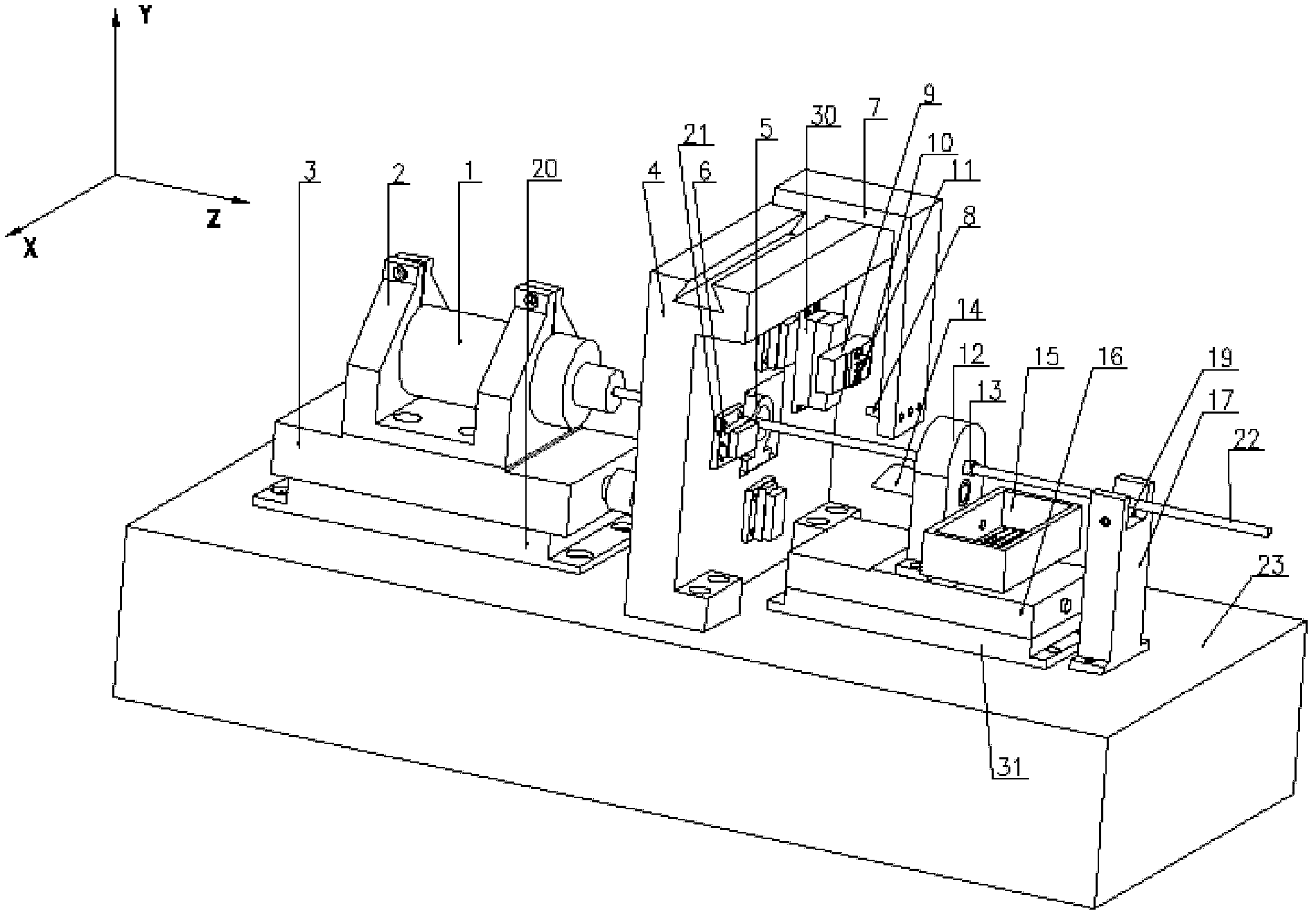

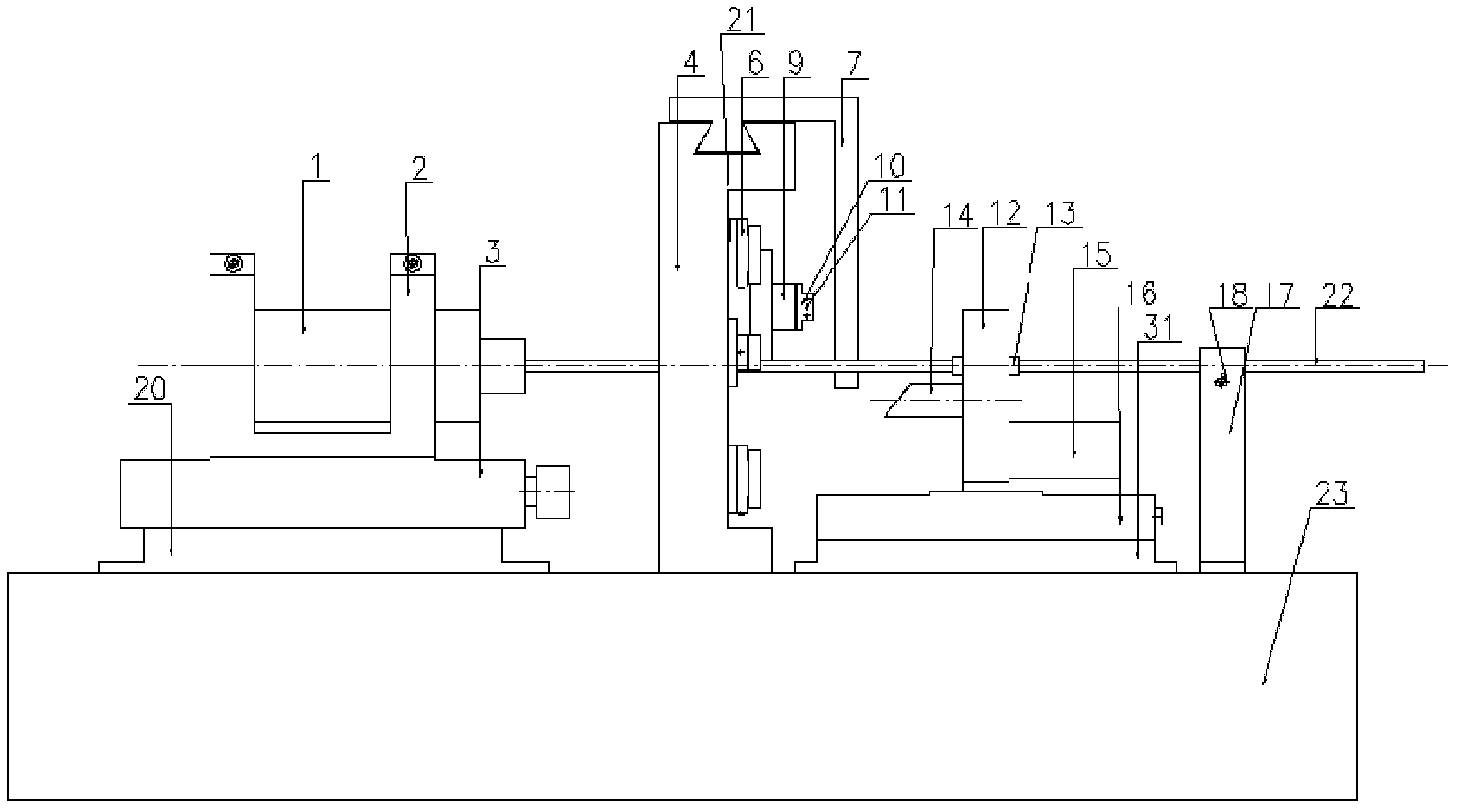

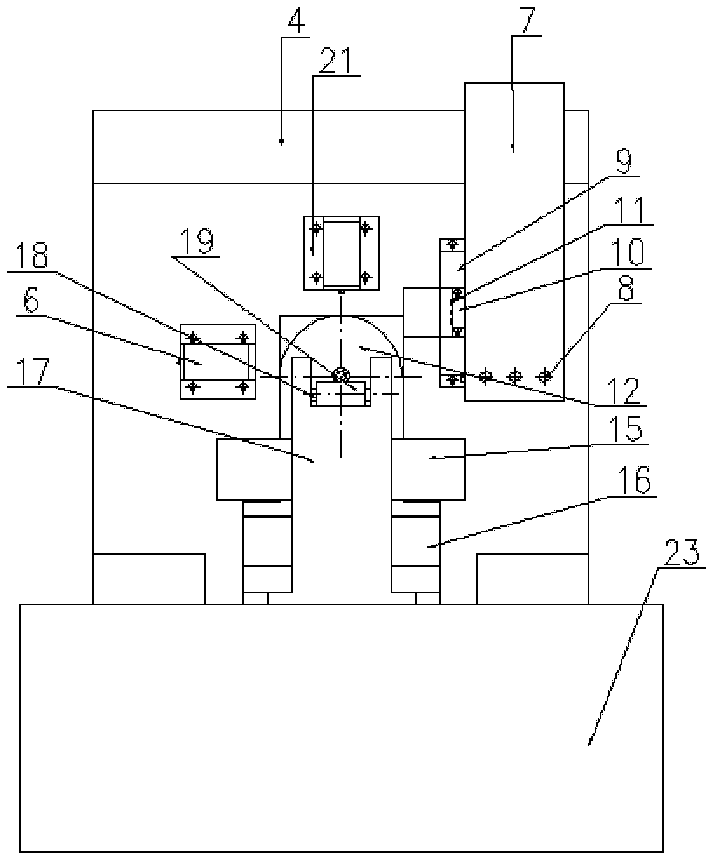

[0070] Embodiment 1 The present invention provides a miniature slitting turning machine tool, which is a multi-functional machine tool mainly for turning, supplemented by milling and drilling. The geometric size of the miniature slitting and turning machine tool is 400×300×300mm, and the size of parts that can be turned is Φ500μm˜Φ5mm.

[0071] The present invention provides a miniature slitting and turning machine tool comprising a spindle unit, a center frame unit, a drilling unit, a milling unit, a feeding unit, an overhanging support unit, a control unit and a machine base 23;

[0072] (1) if figure 1 , 2 As shown, the spindle unit is composed of an electric spindle 1, an electric spindle seat 2, an electric spindle Z-direction sliding table 3, and an electric spindle Z-direction sliding table 20; the electric spindle 1 (Z62-M360.27S5) and The electric spindle Z slide table 3 (ALS-106-H1PB) is a product of Japan Chuo Seiki (CHUO SEIKI) Co., Ltd.;

[0073] Such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com