Meshing type rotating part phase-adjustment tensioning sleeve mechanism

A phase adjustment and tightening sleeve technology, applied in mechanical equipment, transmission parts, gear transmission and other directions, can solve the problems of reducing gear meshing strength, low precision, inconvenient assembly, etc., to ensure assembly accuracy, convenient and reliable mechanism, The effect of reducing duplication of effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

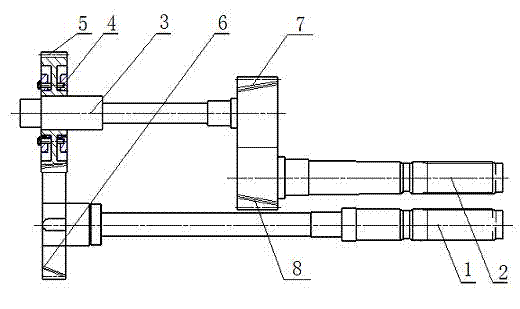

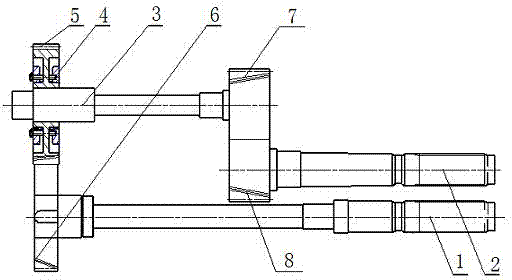

[0010] Such as figure 1 As shown, the phase adjustment tensioning sleeve mechanism of the meshing rotary member includes output shaft 1, output shaft 2, shaft 3, tensioning sleeve 4, gear 5, gear 6, gear 7 and gear 8, and output shaft 1 and gear 6 pass through Single-key connection, output shaft 2 is connected to gear 8, one end of shaft 3 is connected to gear 5 through tensioner sleeve 4, and the other end is connected to gear 7. When adjusting the phase, the phases of output shaft 1 and output shaft 2 are fixed in the design The position of the gear 6 is thus determined. Adjust the tension sleeve without generating tension. Adjust the phase of the gear 5 so that it meshes with the gear 6 at an ideal position, and then increase the tension of the tension sleeve 4 to connect the gear 5 and the gear 5. The shafts 3 are connected together, so as to achieve the phase adjustment of the two output shafts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com