Strain measuring method for large-scale prestressed wire winding machine frame

A technology of prestressed steel wire and measurement method, applied in the field of strain measurement, can solve problems such as difficult engineering, many patch points, easy to produce errors, etc., and achieve the effect of solving heavy workload and ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with the examples, the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

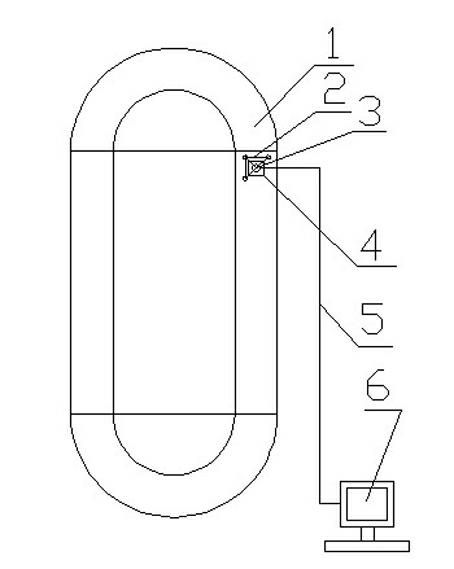

[0021] see figure 1 , figure 2 , a method for measuring the frame strain of a large prestressed steel wire winding machine, according to the following steps:

[0022] In the first step, surface treatment is carried out on the measurement area 4 on the press frame 1, so that the area can achieve an ideal measurement effect.

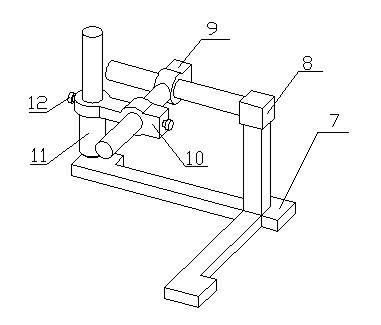

[0023] In the second step, the lens fixing and moving device 2 is installed in the measurement area 4. The lens fixing and moving device 2 is composed of a mounting bracket 7, an up and down translation mechanism 8 assembled on the installation bracket 7, and an up and down translation mechanism. The left and right translation mechanism 9 on the 8 and the front and rear translation mechanism 10 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap