Vehicle wheel tire bump detector

A detection device and tire technology, which is applied in the field of tire burst warning device and tire bulge, to achieve the effect of rigidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

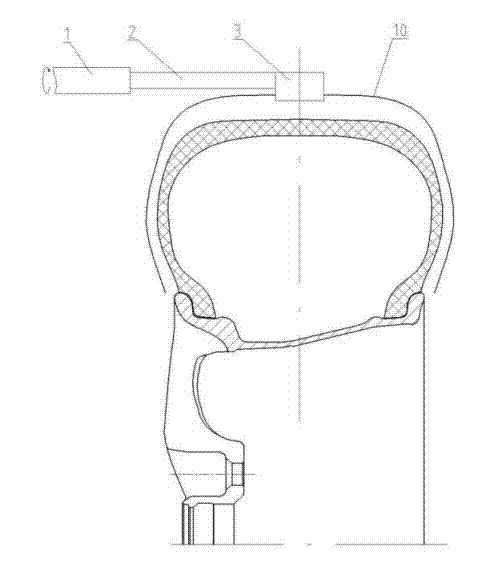

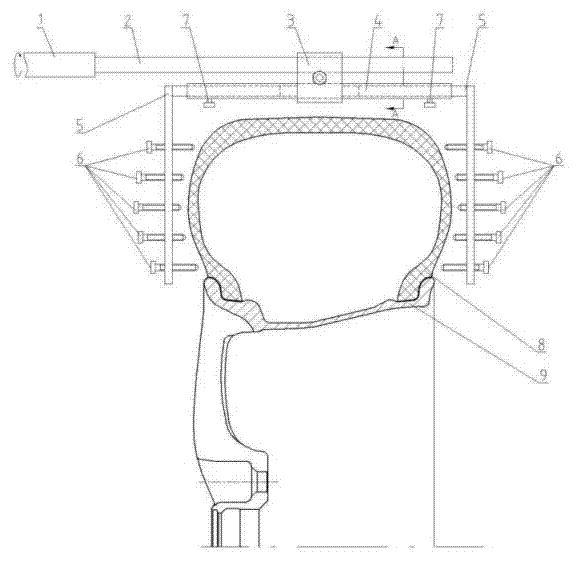

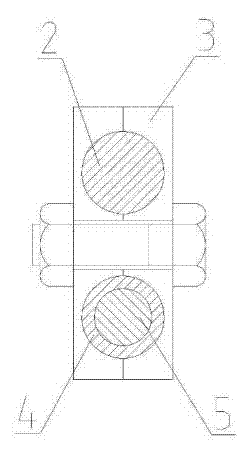

[0021] in figure 2 Among them, one end of the rotary limit switch 1 is connected with the alarm and shutdown system of the equipment, and the other end is connected with the straight rod 2. A special clamp 3 is installed on the straight rod 2. After the nut of the clamp 3 is loosened, it can move at any position along the straight rod 2. During normal operation, adjust the clamp 3 on the straight rod according to the deviation of the wheel (ET). 2 on the position and tighten the nut. The other end of the clamp 3 is clamped in the middle of the sleeve 4 and fastened. Both ends of the sleeve 4 are respectively equipped with an L-shaped detection arm 5, and the cylindrical end of the L-shaped detection arm 5 is inserted into the sleeve and can be extended and contracted to adapt to the difference in the width of the wheel and tire. The L-shaped detection arm 5 is connected with the casing tube by tightening the top wire 7 to fix the relative position. A certain number of thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com