Method for judging the feeding time of automatic detergent feeding system and washing machine

A technology of automatic feeding and time feeding, applied to other washing machines, washing machine control devices, washing devices, etc., can solve problems such as waste, achieve the effects of improving efficiency, realizing full automation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

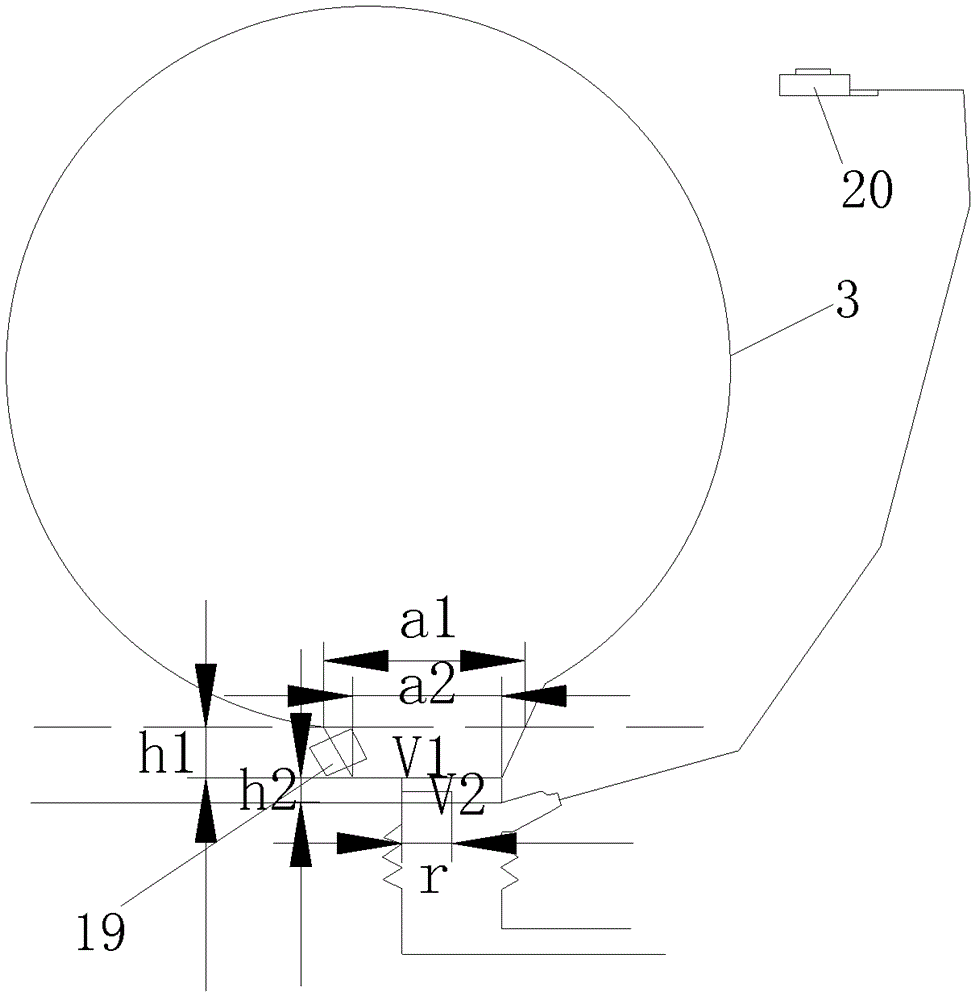

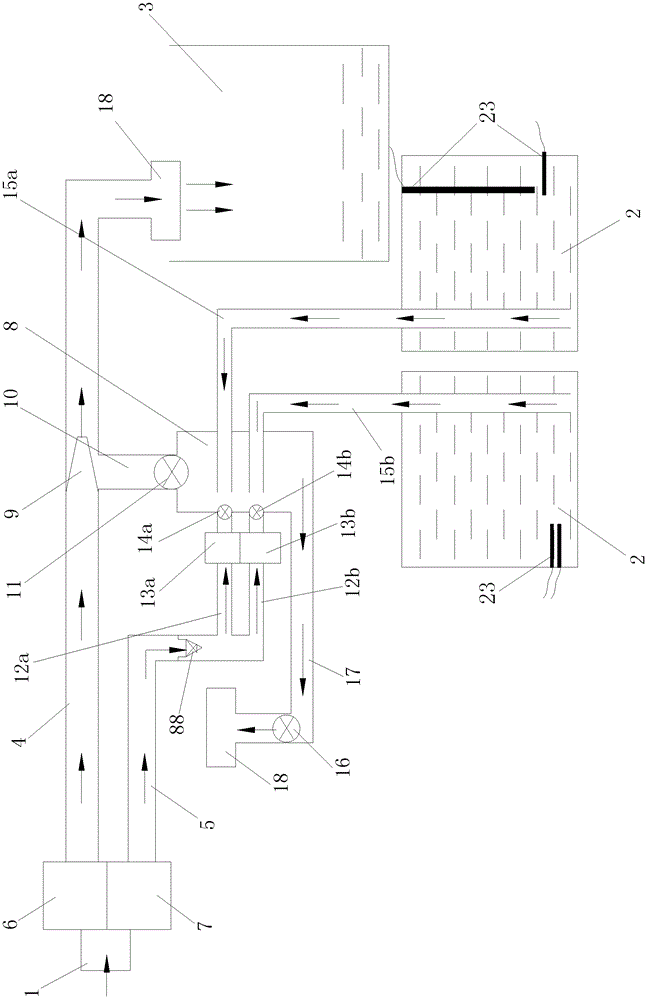

[0053] Such as image 3 As shown, the washing machine according to the present invention includes a water inlet 1, a detergent container 2 and a water tank 3, and two water inlet passages are arranged between the water inlet 1 and the water tank 3, which are respectively the main water inlet 4 and the cleaning water way 5. There is a main water inlet valve 6 between the main water inlet 4 and the water inlet 1, a cleaning water valve 7 between the cleaning waterway 5 and the water inlet 1, and a constant volume container between the cleaning waterway 5 and the water tank 3 8. The constant volume container 8 communicates with the detergent container 2. The main water inlet 4 is provided with a Venturi tube 9 capable of generating negative pressure through the flow of water. The rear side of the outlet of the Venturi tube 9 is provided with a side branch pipe 10 and constant volume The container 8 is connected, and the water flow of the main water inlet 4 passes through the Vent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com