Patents

Literature

34results about How to "Avoid overdelivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

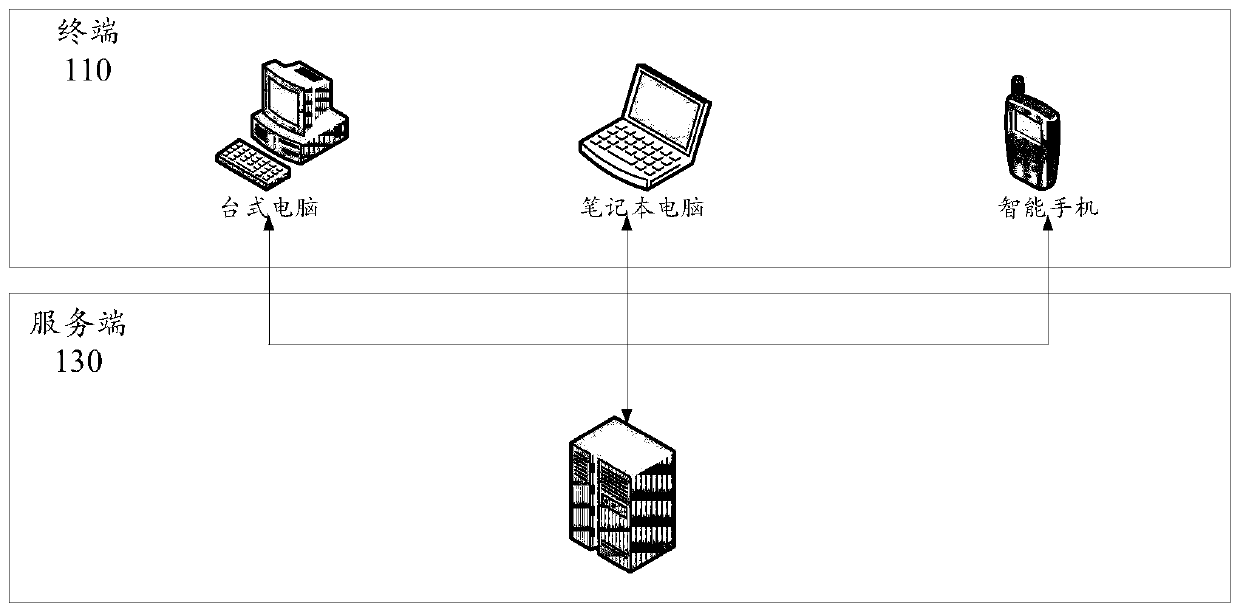

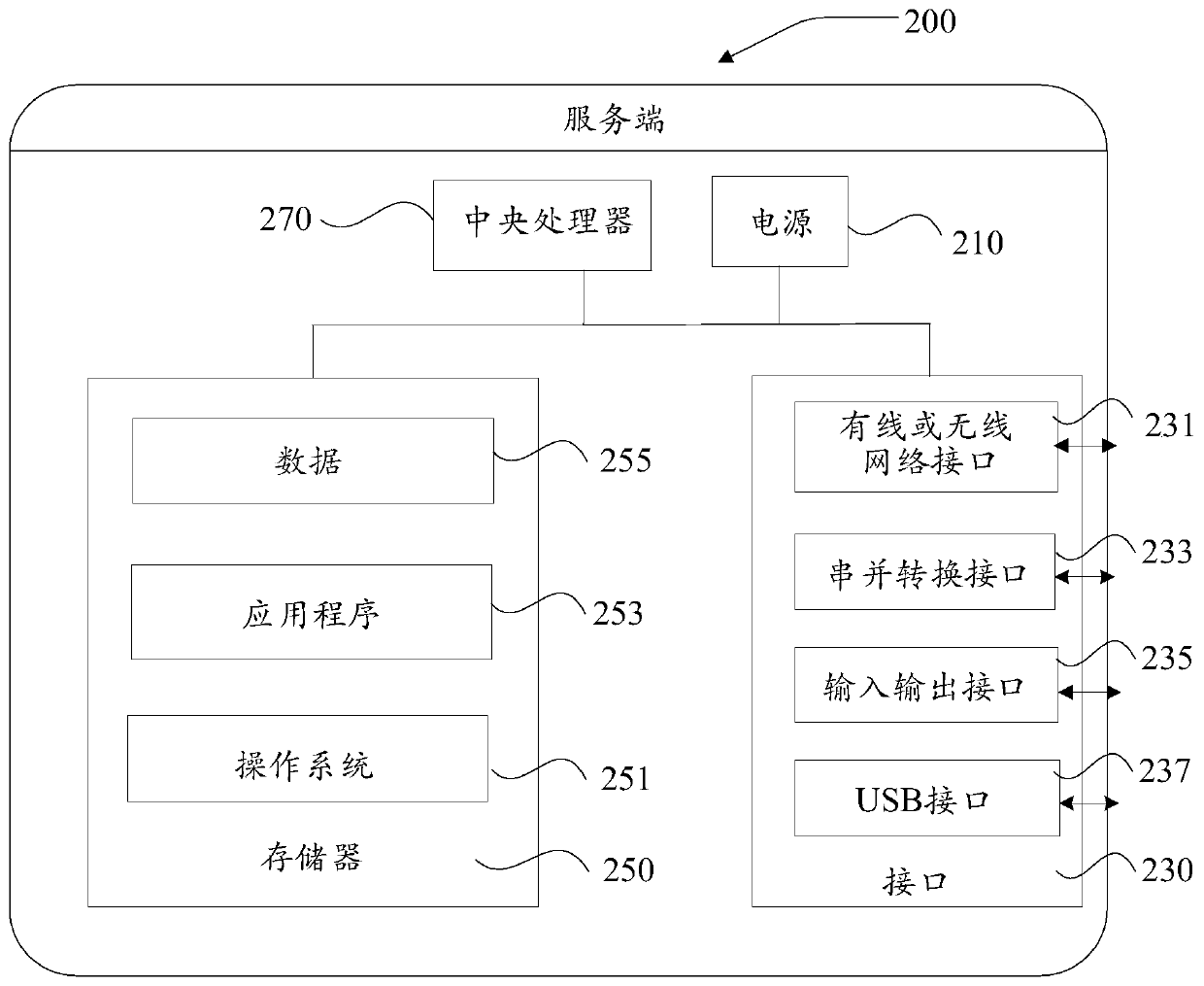

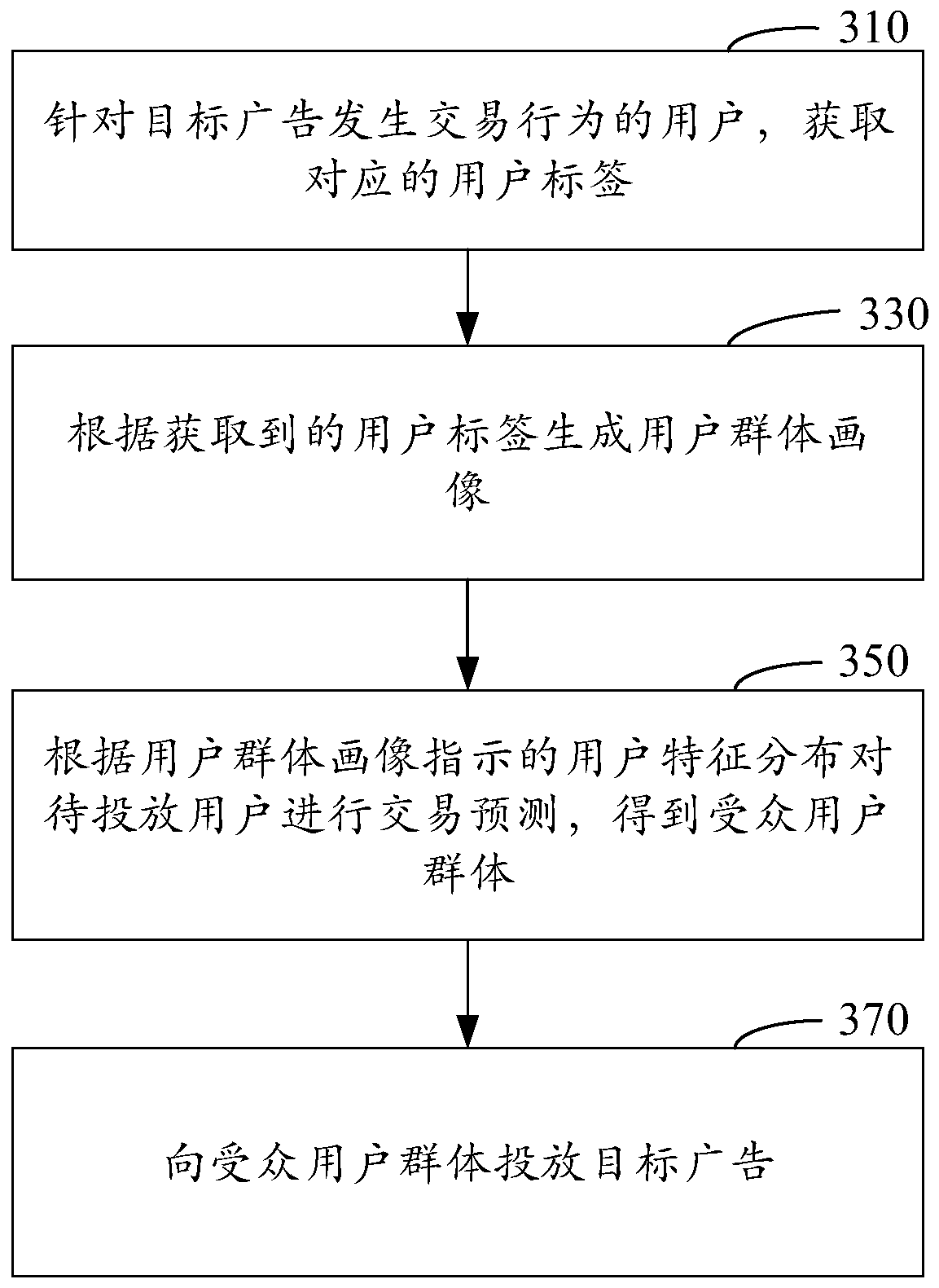

Advertisement putting method and device based on big data analysis and electronic equipment

PendingCN109784973AAvoid overdeliveryImprove the advertising experienceMarketingElectric equipmentData science

The invention belongs to the technical field of big data, and relates to an advertisement putting method and device based on big data analysis and electronic equipment, and the method comprises the steps: obtaining a corresponding user label for a user who generates a transaction behavior of a target advertisement; Generating a user group portrait according to the obtained user label, wherein theuser group portrait is used for indicating user feature distribution corresponding to a user who generates a transaction behavior for the target advertisement; Carrying out transaction prediction on to-be-released users according to the user feature distribution indicated by the user group portrait to obtain an audience user group; And delivering the target advertisement to the audience user group. According to the advertisement putting method and device based on big data analysis and the electronic equipment, the problem that in the prior art, the accuracy of advertisement putting conducted for different products is not high is solved.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

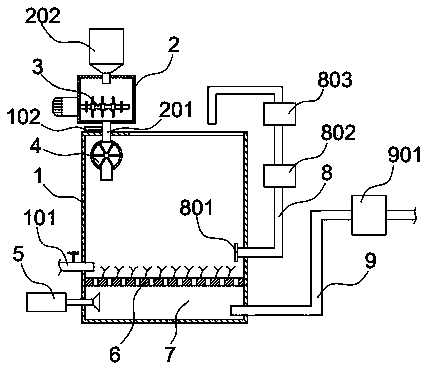

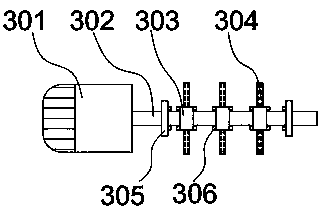

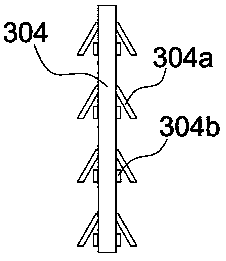

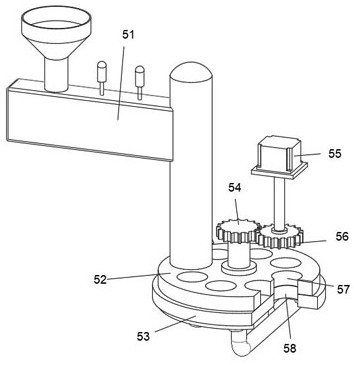

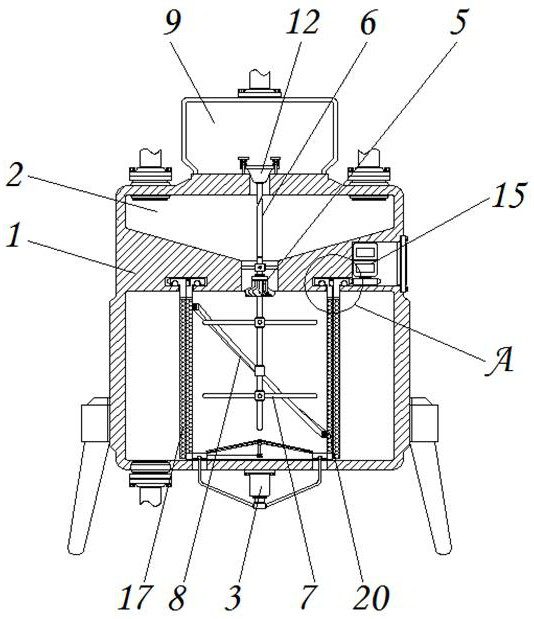

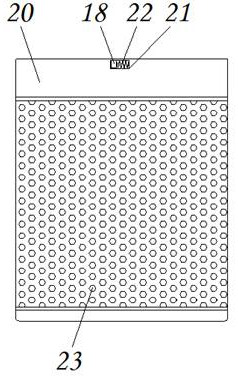

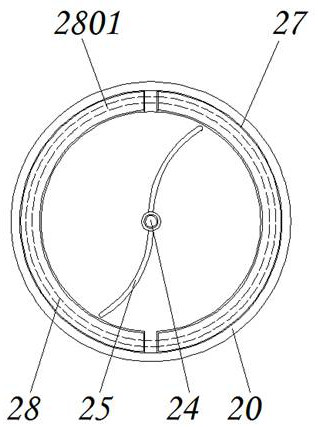

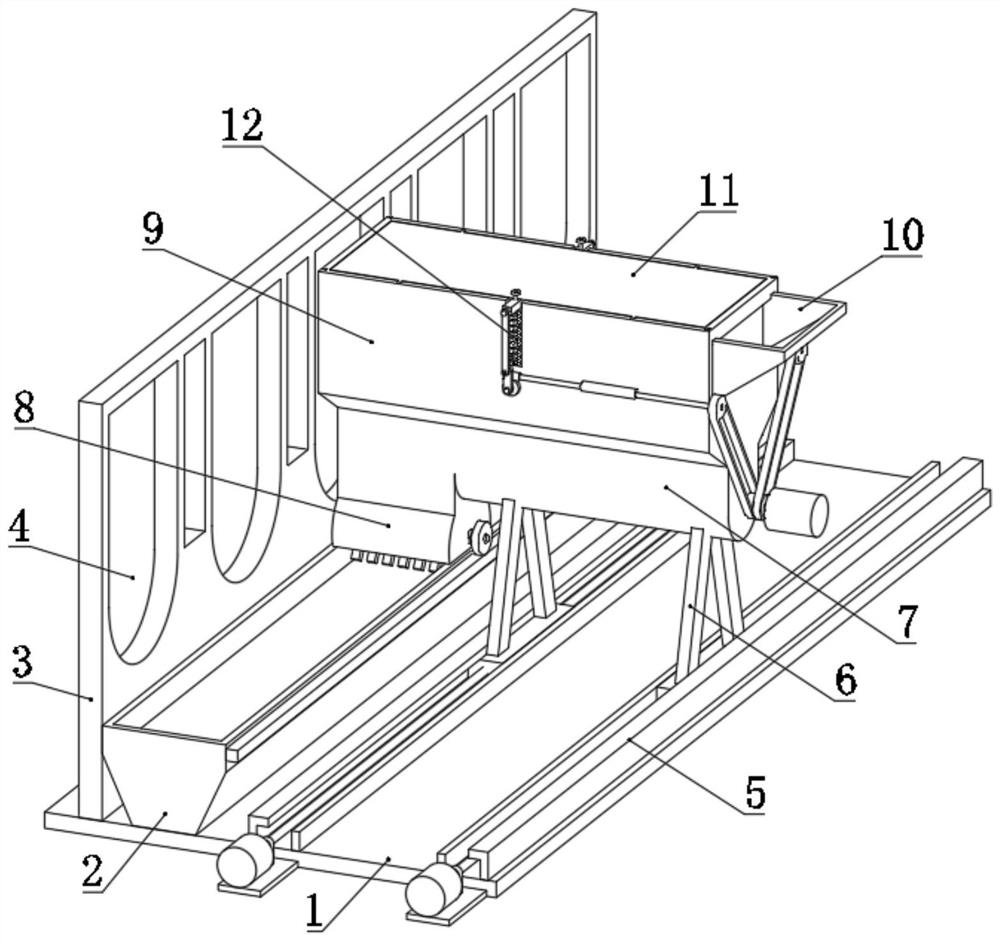

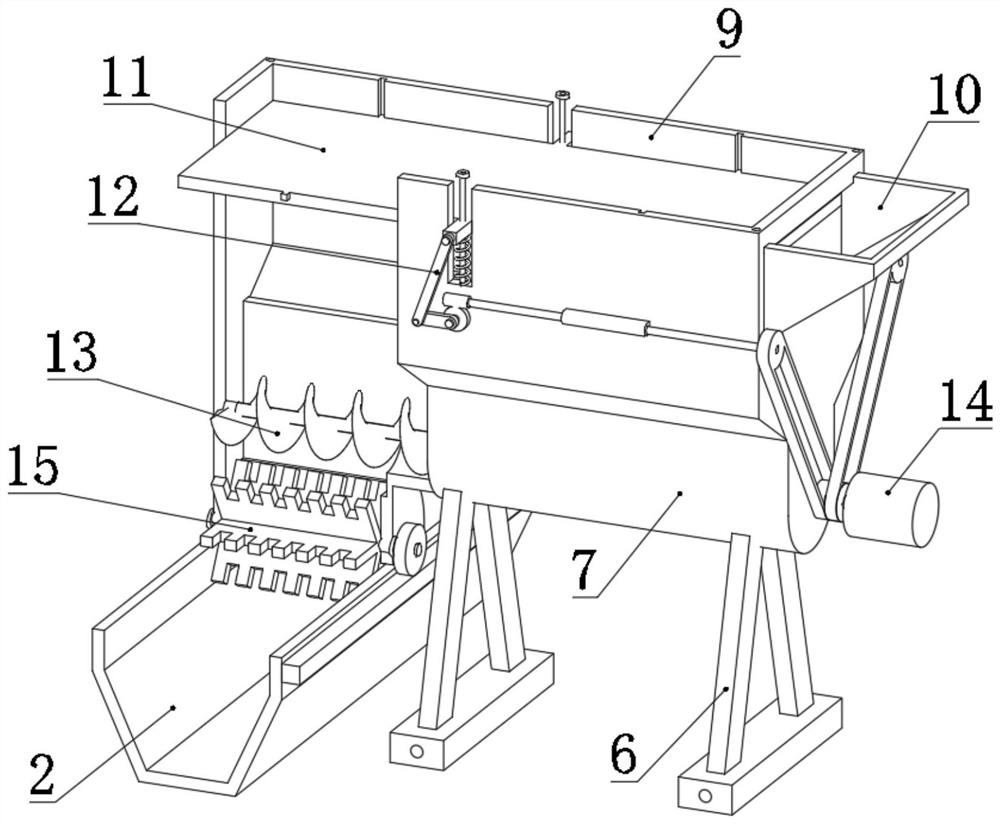

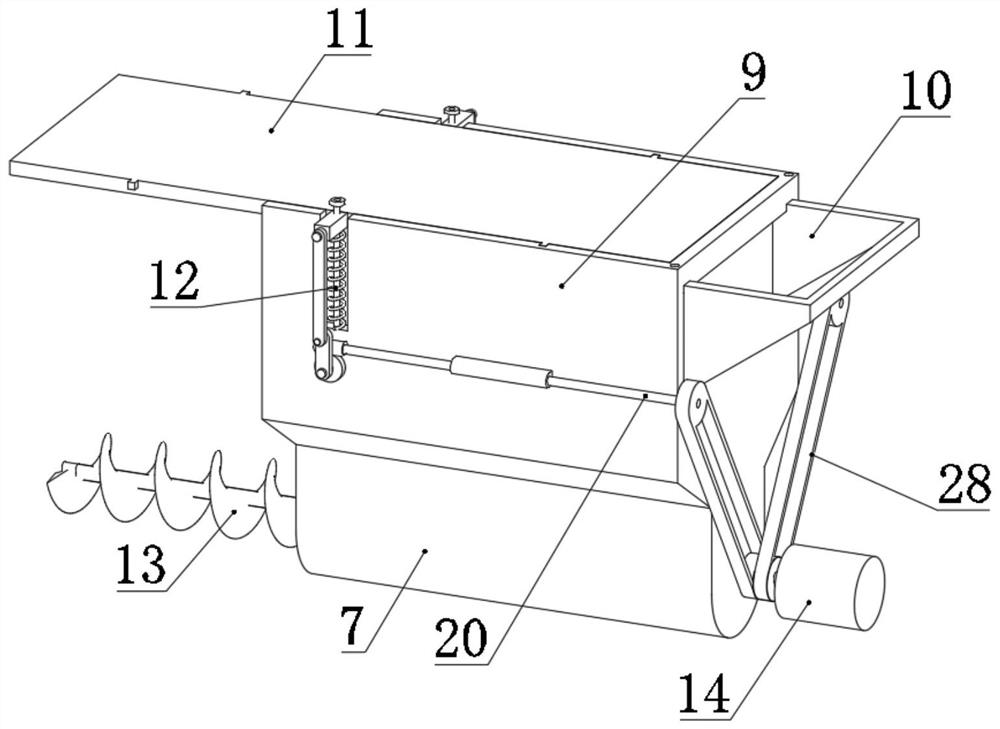

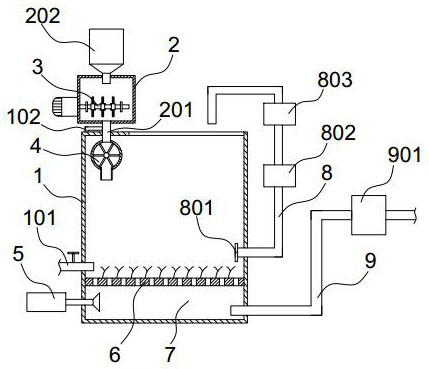

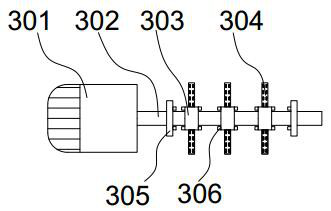

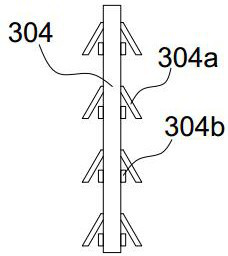

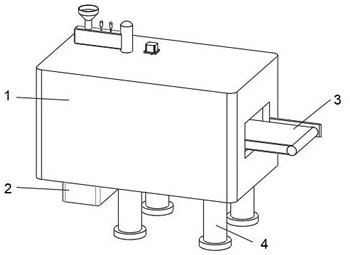

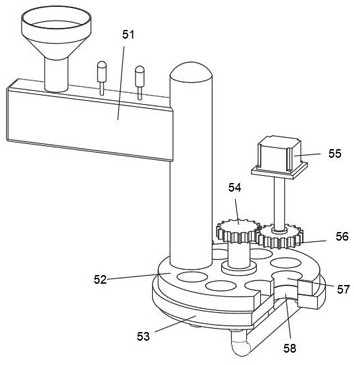

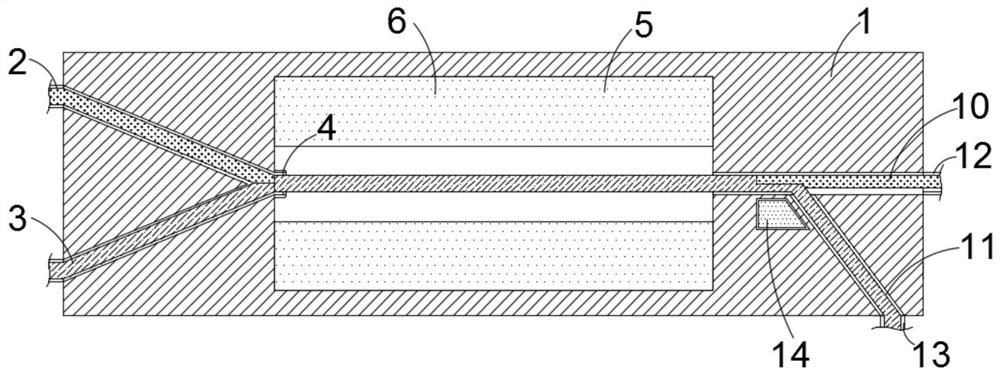

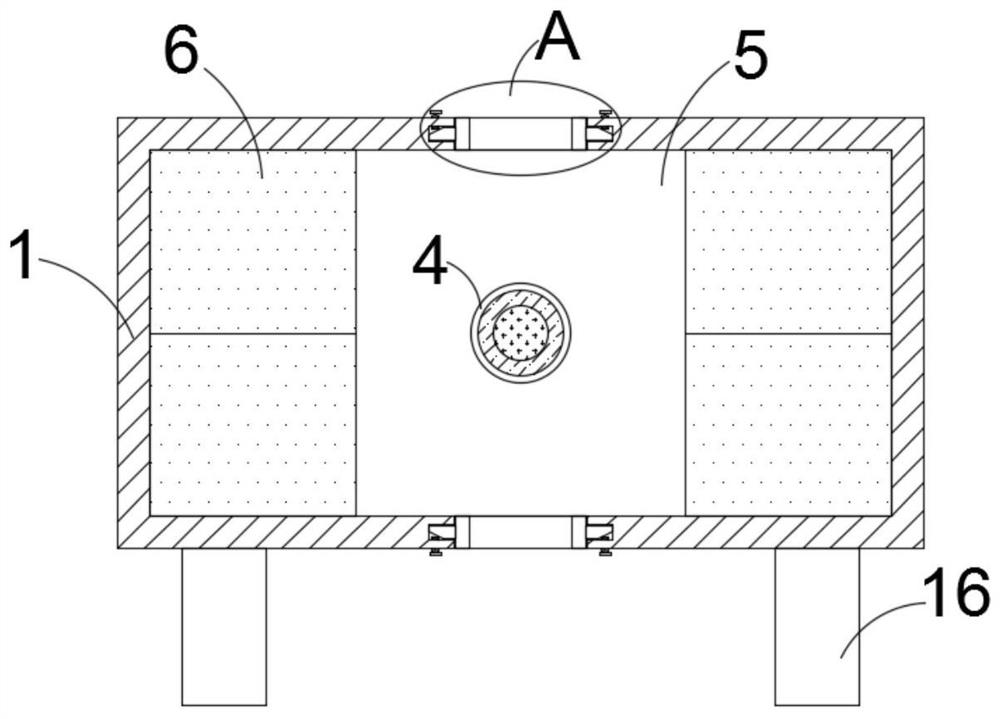

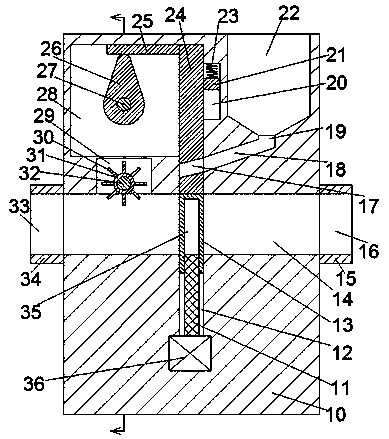

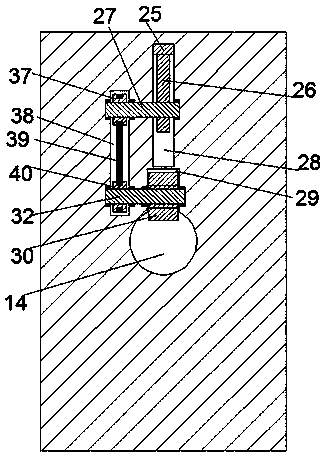

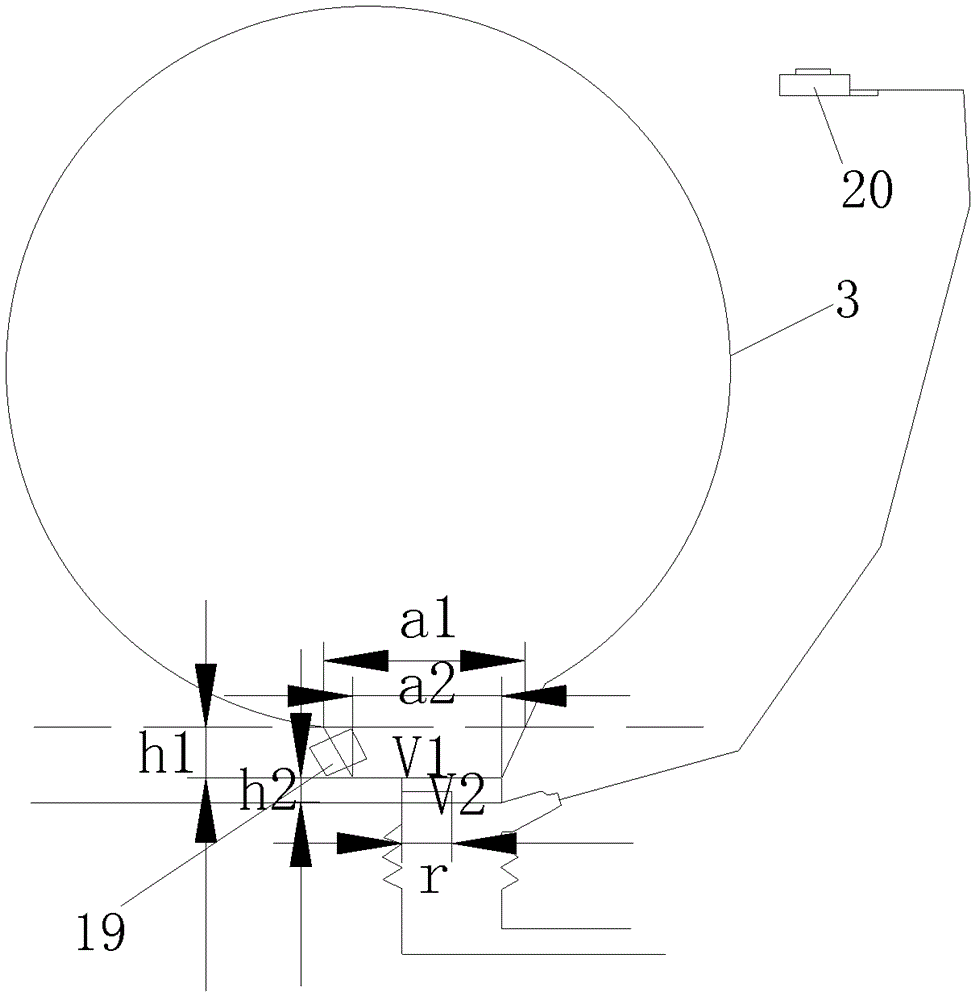

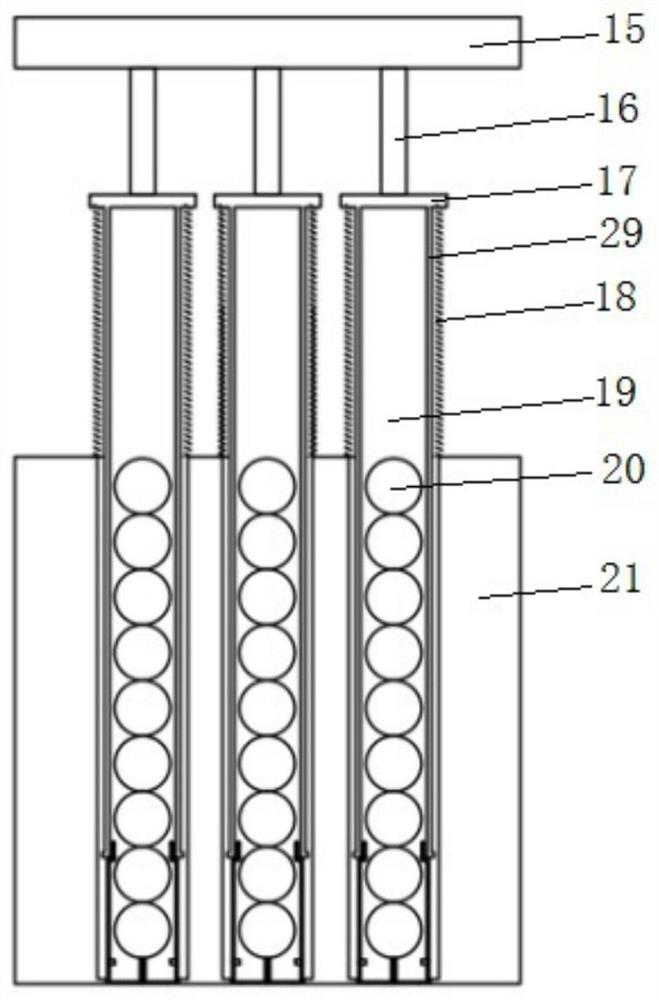

Marine culture device equipped with feed recovery drum

ActiveCN108575862AAvoid wastingImprove firmnessClimate change adaptationPisciculture and aquariaMarine cultureAgricultural science

The invention discloses a marine culture device equipped with a feed recovery drum. The marine culture device comprises a cylindrical culture box used for culturing, wherein the bottom part of the interior of the culture box is separated into the feed recovery drum through a partition plate; the marine culture device also comprises a feed distribution mechanism used for feeding a feed; a stirringbox is connected with and arranged above the feed distribution mechanism through a conveying pipe; the upper part of the stirring box is connected with a feeding hopper; one side of the interior of the feed recovery drum is connected with a water conveying pump; and the other side of the interior of the feed recovery drum is connected with a collection pipe which is connected with a liquid suctionpump. The marine culture device provided by the invention can effectively solve the death of a cultured animal due to turbidity of a culture water body, effectively improves the survival rate of thecultured animal, and can realize controllable feeding and recycling of the feed.

Owner:金华市凌特水产养殖技术有限公司

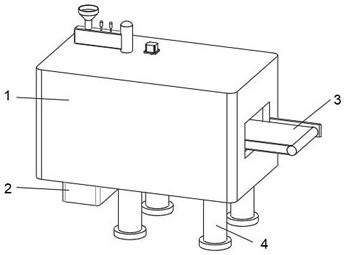

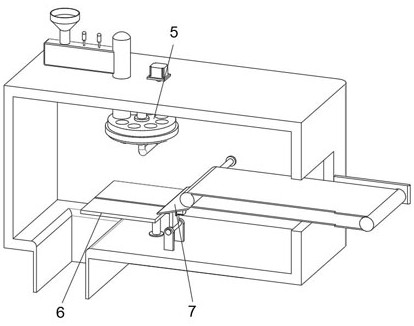

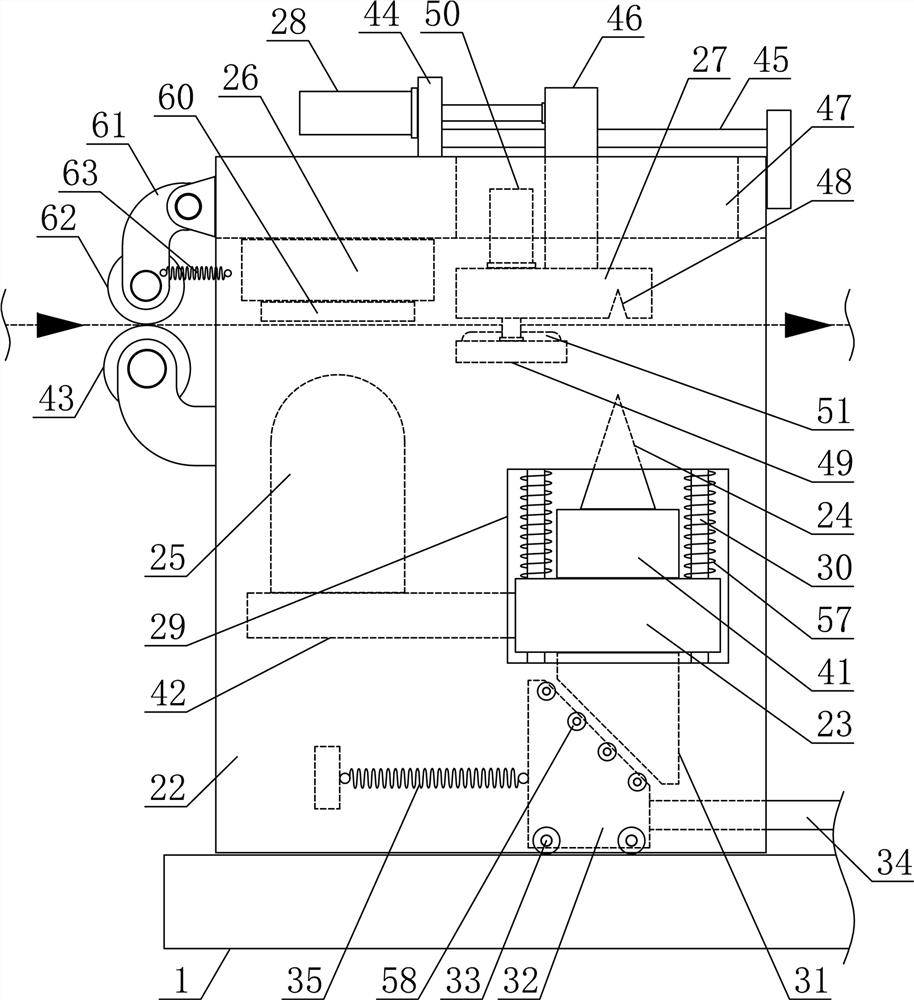

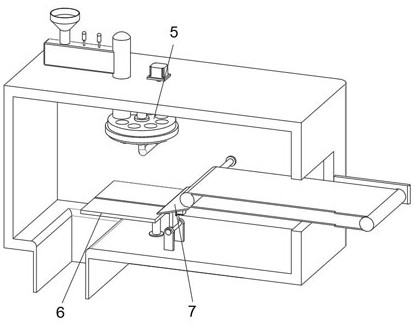

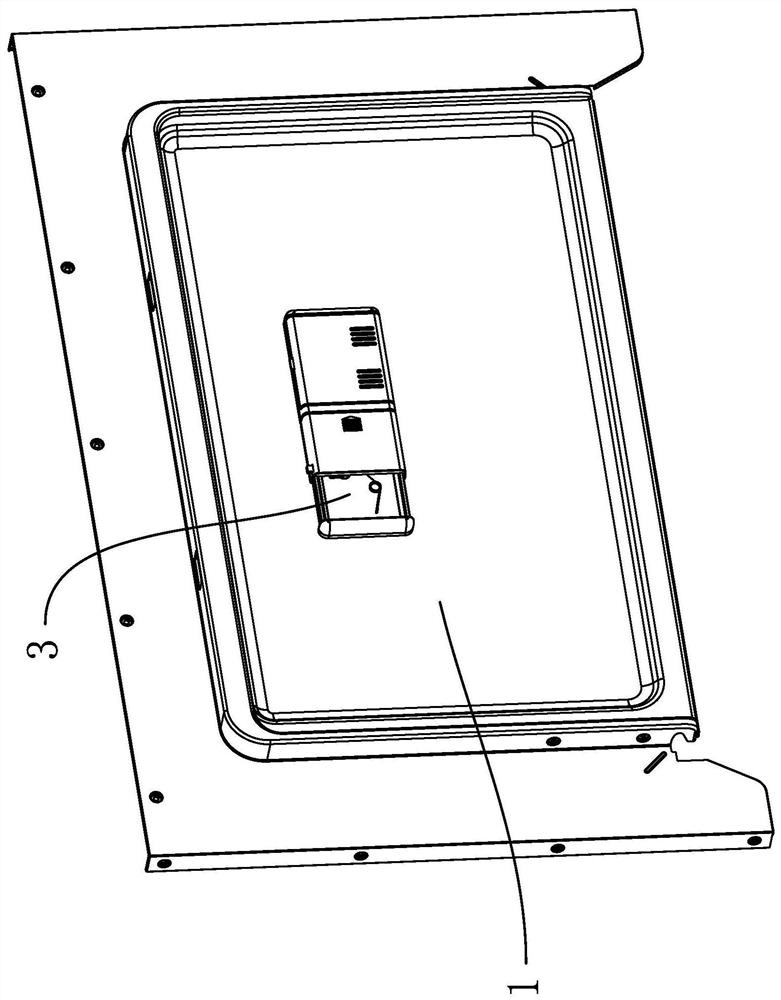

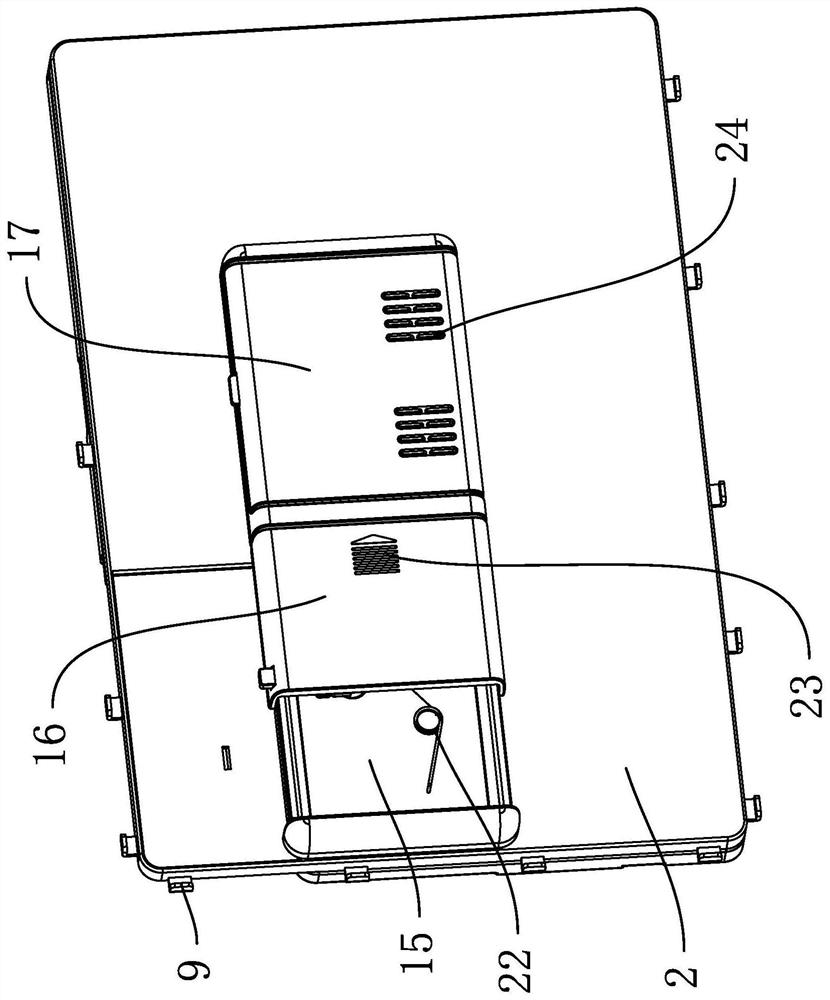

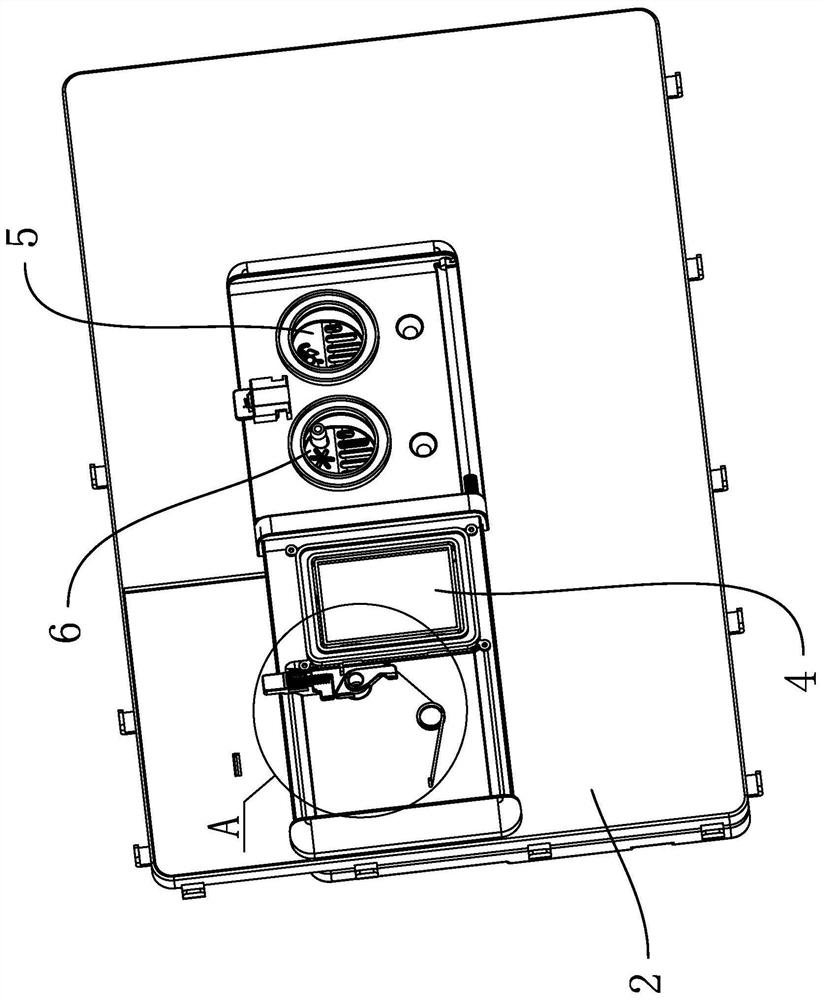

Clothing packaging equipment for clothing production

ActiveCN113371256AFacilitate functioningAvoid overdeliveryPackagingElectrostatic chargesMechanical engineeringIndustrial engineering

The invention provides clothing packaging equipment for clothing production, and relates to the technical field of clothing packaging. The clothing packaging equipment for clothing production comprises a box body, a clothing conveying belt, a clothing folding mechanism and a clothing storage auxiliary bag feeding mechanism, wherein a plurality of supporting legs are fixedly connected to the lower surface of the box body, and a discharging pipe communicating with the interior of the box body is fixedly connected to the lower surface of one end of the box body; the clothing conveying belt is installed on the box body, the clothing conveying belt penetrates through a feeding opening formed in the outer surface of the box body, and a guide plate which is obliquely arranged downwards is fixedly connected to the discharging end of the clothing conveying belt; the clothing folding mechanism is connected to the box body, and the clothing folding mechanism is located below the guide plate; and the clothing storage auxiliary bag feeding mechanism is connected to the box body. The clothing packaging equipment for clothing production has the advantage that the clothing storage auxiliary bag can exert the effect.

Owner:南通寝尚纺织品有限公司

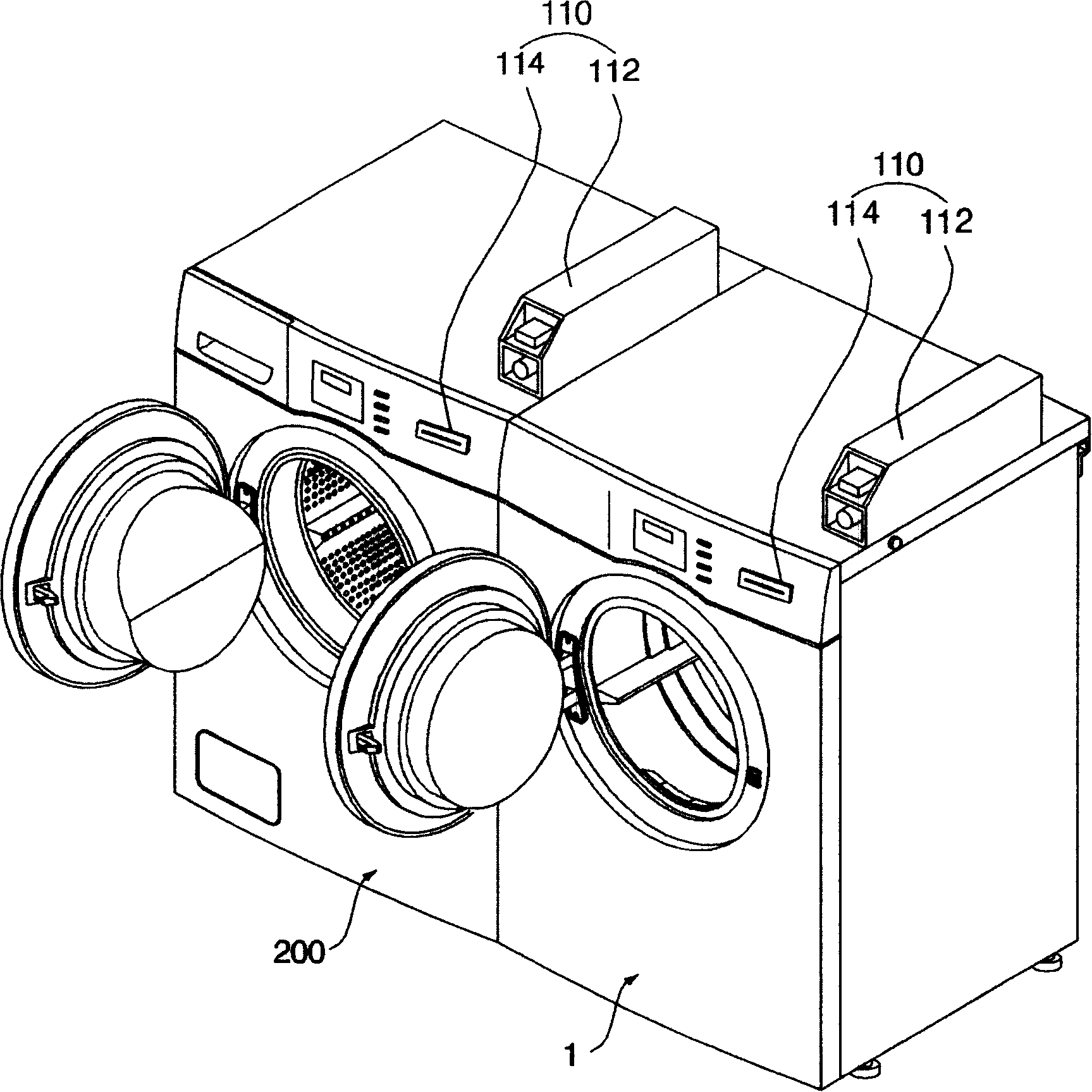

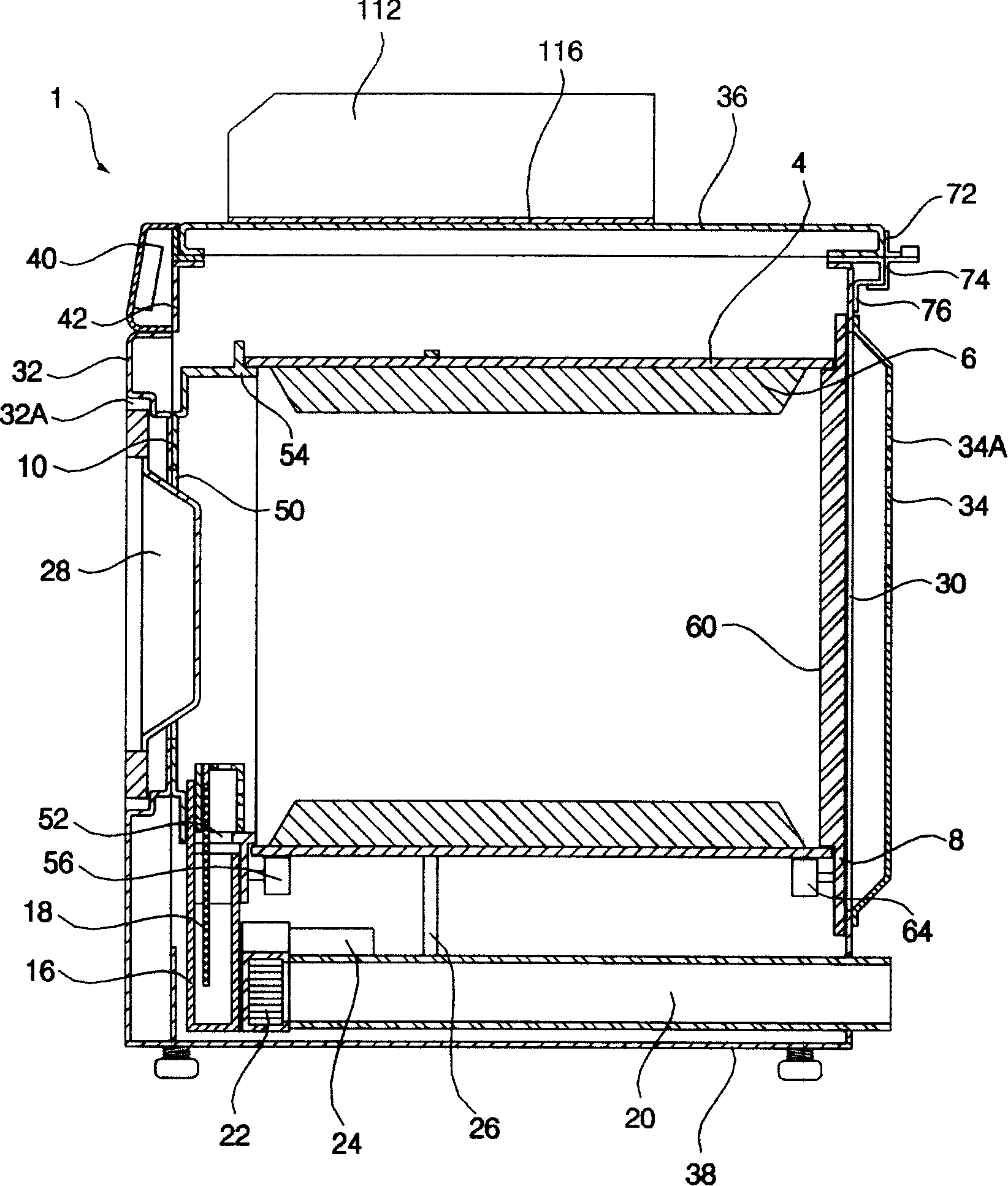

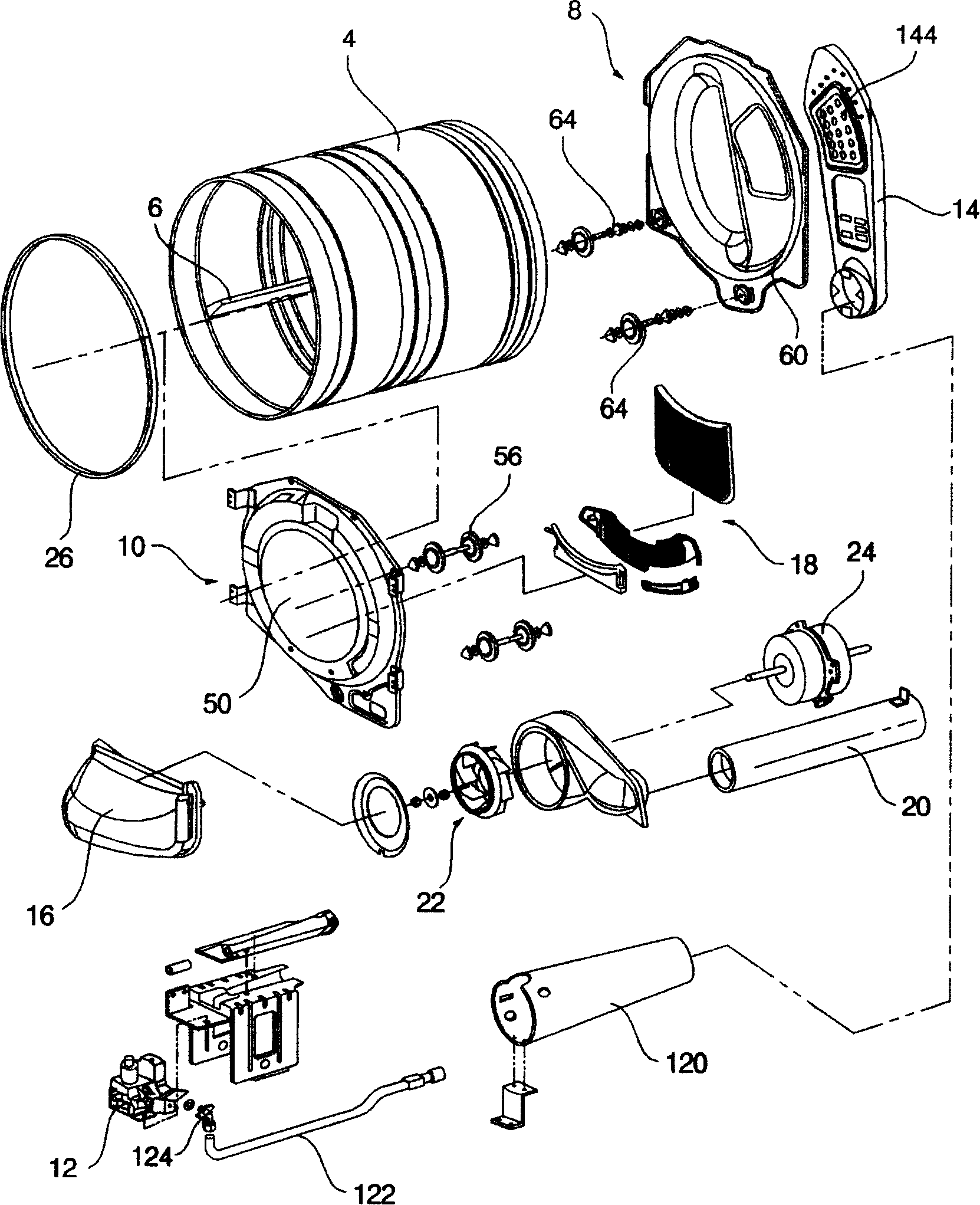

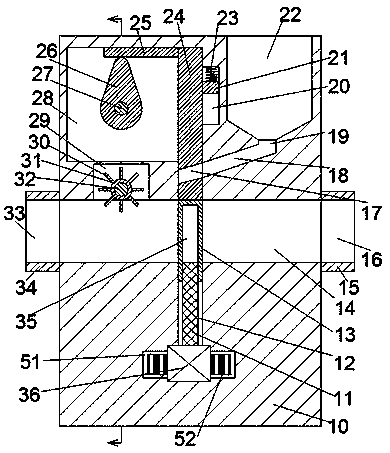

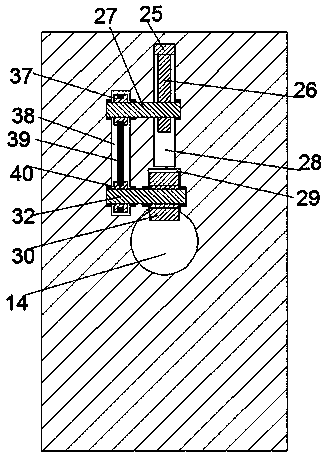

Scouring agent feeding mechanism of scouring apparatus

InactiveCN101177898AAvoid overdeliveryPreventing the phenomenon of adding detergentOther washing machinesTextiles and paperEngineeringScouring agent

Owner:NANJING LG PANDA APPLIANCES

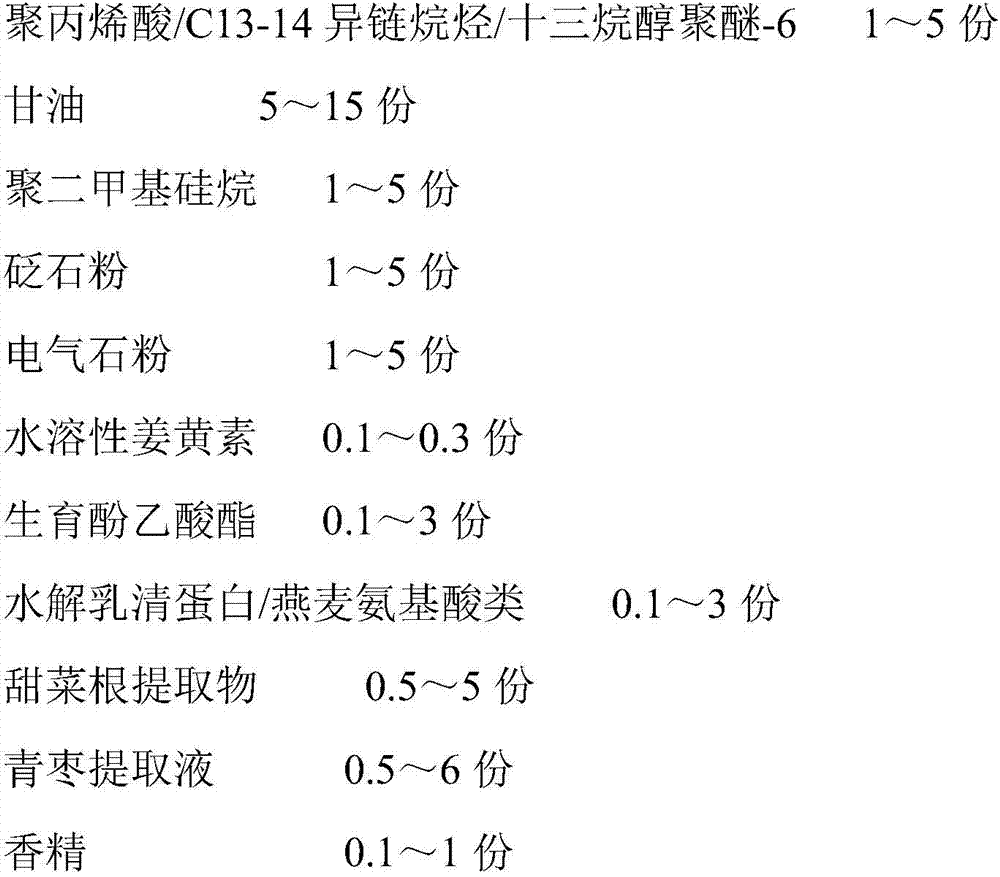

Stone needle freckle removing skin care product and preparation method thereof

ActiveCN105078843APromote detoxificationPromote absorptionCosmetic preparationsToilet preparationsHydrolysateGlycerol

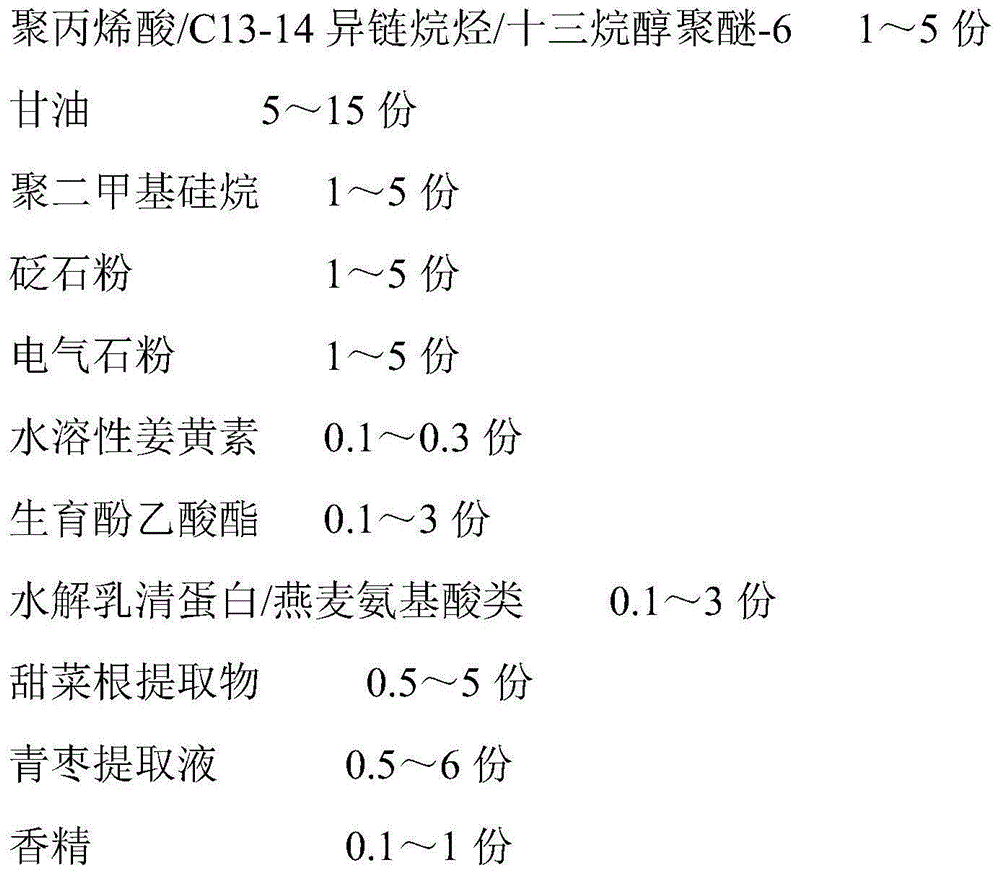

The invention discloses a stone needle freckle removing skin care product and a preparation method thereof, and relates to the field of a skin care product, wherein the skin care product consists of 1-5 parts of polyacrylic acid / C13-14 isoparaffin / trideceth-6, 5-15 parts of glycerol, 1-5 parts of polydimethylsilane, 1-5 parts of stone needle powder, 1-5 parts of tourmaline powder, 0.1-0.3 parts of water-soluble curcumin, 0.1-3 parts of tocopheryl acetate, 0.1-3 parts of whey protein hydrolysate / oat amino acids, 0.5-5 parts of a beet root extract, 0.5-6 parts of a green jujube extracted solution, 0.1-1 part of essence and the balance of pure water or mineral water. The skin care product disclosed by the invention can be used for continuously whitening; and the skin care product is not only relatively low in cost but also capable of keeping the skin under a healthy status.

Owner:HUBEI MULAN TONGDA TECH

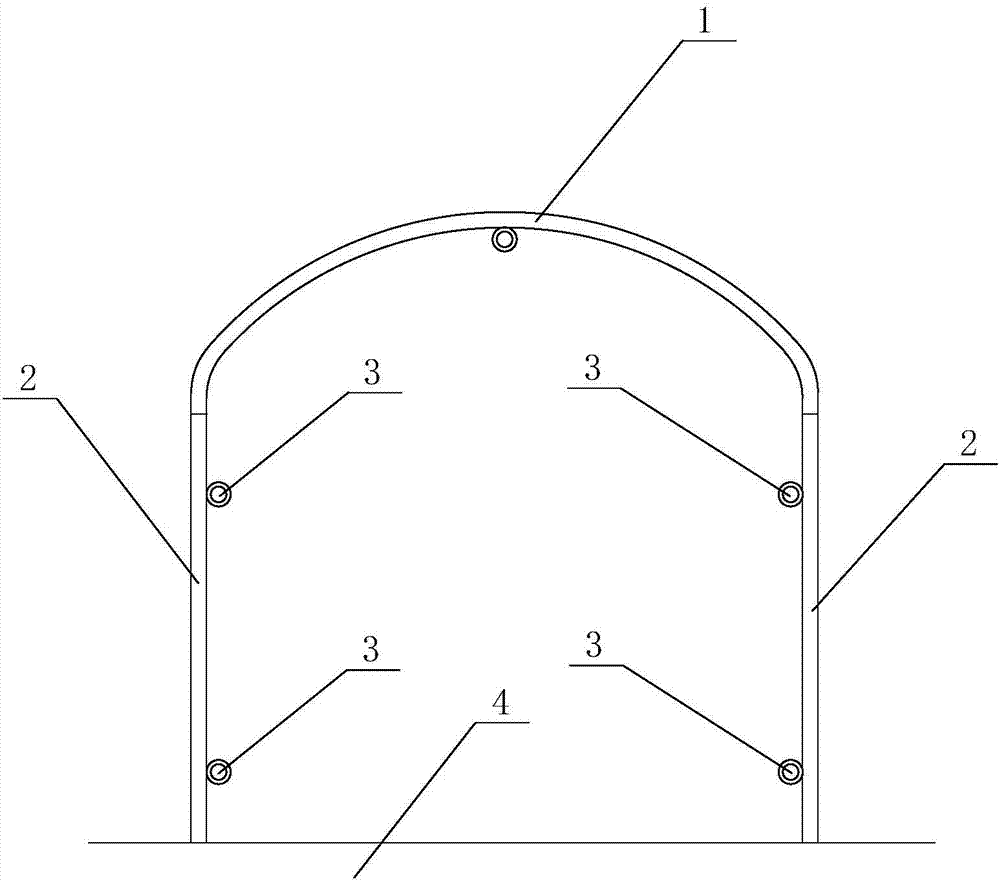

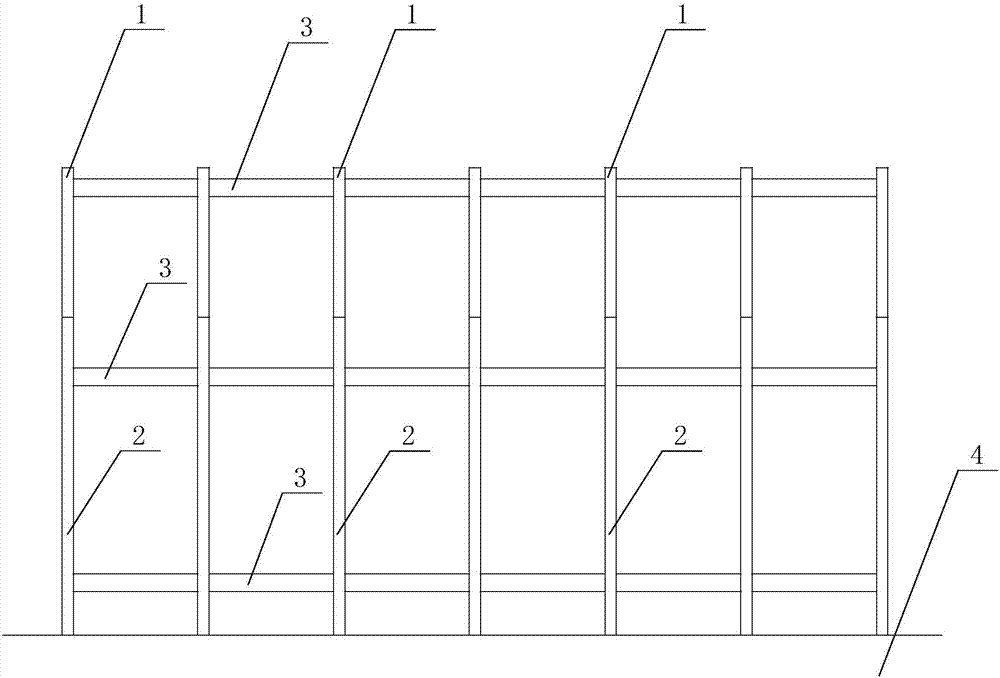

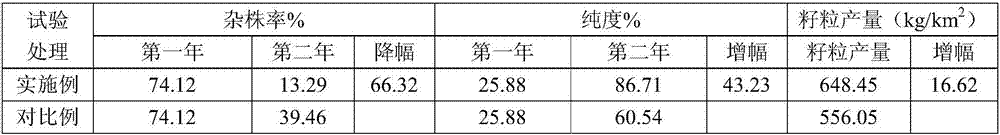

Method and matched separation net house for purifying and rejuvenating orychophragmus violaceus

InactiveCN107295892ALow input costAvoid overdeliveryPlant genotype modificationHorticultureGreenhousePollination

The invention discloses a method for purifying and rejuvenating orychophragmus violaceus. The method includes steps of building a separation net house; sowing seeds at equal row spacing; carrying out top dressing once; removing abnormal plants; releasing osmia; harvesting seeds and the like. The invention further provides the matched separation net house. The matched separation net house comprises greenhouse films or sunshade nets, separation net covers and a support frame. The support frame is used for supporting the separation net covers. The method and the matched separation net house have the advantages that merits of low-temperature resistance, high pollination speeds, good pollination effects, simplicity and convenience in management and the like of the osmia are used with the separation net house, accordingly, the orychophragmus violaceus purification and rejuvenation efficiency can be effectively improved, and seed production requirements can be met.

Owner:SHANDONG CROP GERMPLASM CENT

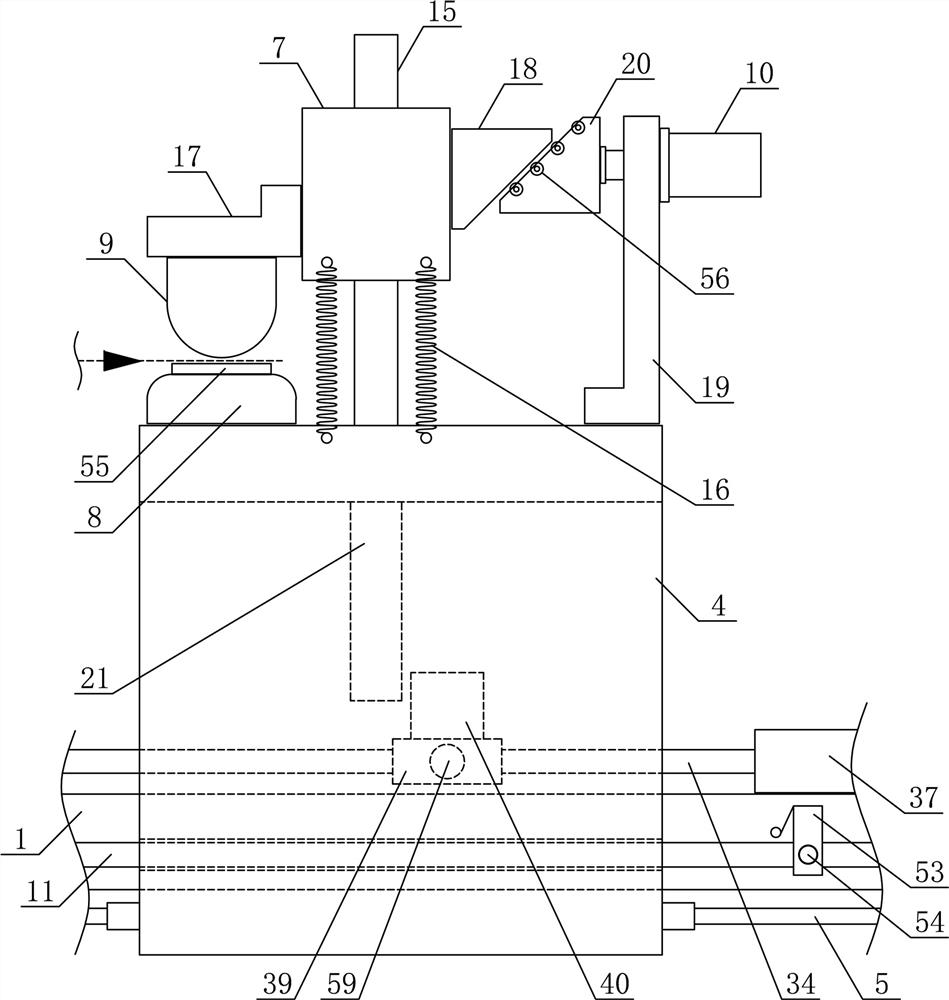

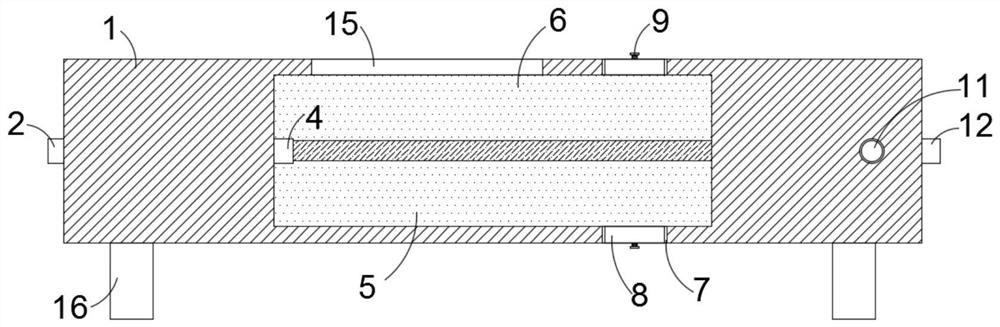

Fabric cutting device for silk quilt production

InactiveCN112850312AStable cutting processEfficient and stable cuttingArticle deliveryStructural engineeringMechanical equipment

The invention discloses a fabric cutting device for silk quilt production, and belongs to the field of home textile processing mechanical equipment. A fabric pressing and cutting mechanism and a fabric pulling and conveying mechanism of the fabric cutting device are arranged on the two sides of a fabric processing support, the two sides of the upper side of a reciprocating pulling chain are fixedly connected with the two sides of the lower side of a fabric pulling and conveying support correspondingly, a pressing plate mounting connecting plate and a lifting fixing wedge plate are horizontally and fixedly arranged on the two sides of the upper side of a lifting reciprocating guide plate correspondingly, a fabric pulling and conveying lower bearing plate is horizontally and fixedly arranged on the fabric pulling and conveying support on the lower side of a fabric pulling and conveying upper pressing plate, a pressing and cutting fixing wedge plate is horizontally and fixedly arranged on the lower side of a pressing and cutting lifting plate, a translation pressing and cutting wedge plate matched with the pressing and cutting fixing wedge plate is horizontally arranged on the fabric processing support on the lower side of the pressing and cutting fixing wedge plate, and a fabric pressing cutter is horizontally and fixedly arranged on the upper side of a cutter mounting base. The fabric cutting device for silk quilt production is reasonable in structural design, silk quilt fabric can be efficiently, stably, continuously and accurately cut in a sectional mode, the processing automation degree is high, and the requirements of production and use are met.

Owner:桐乡市诺创信息科技有限公司

Flocculation decontamination type industrial sewage treatment device

InactiveCN112093869AAvoid overdeliveryImprove practicalitySpecific water treatment objectivesHollow article cleaningFlocculationSewage treatment

The invention discloses a flocculation decontamination type industrial sewage treatment device, which comprises a device main body, an electric push rod, a cleaning brush and a servo motor, a water collecting bin is formed in the upper end of the device main body, a liquid storage barrel is arranged at the upper end of the device main body, and a rubber plug penetrates through the outer side of aguide column; a servo motor is arranged on the inner side of the device body, a sleeve is connected to a bearing on the inner side of the device body, a reaction barrel is connected to a bearing on the inner side of the device body, a second through hole is formed in the side wall of the reaction barrel, and a sewage discharging hole is formed in the bottom of the reaction barrel. According to theflocculation decontamination type industrial sewage treatment device, a potential energy driving device during sewage injection can be used for automatically and quantitatively discharging accordingto the sewage treatment capacity, excessive or insufficient adding of a flocculating agent is avoided, and meanwhile, flocculation gel lumps generated in the flocculation decontamination type industrial sewage treatment device can be automatically dehydrated and cleaned.

Owner:洪木兰

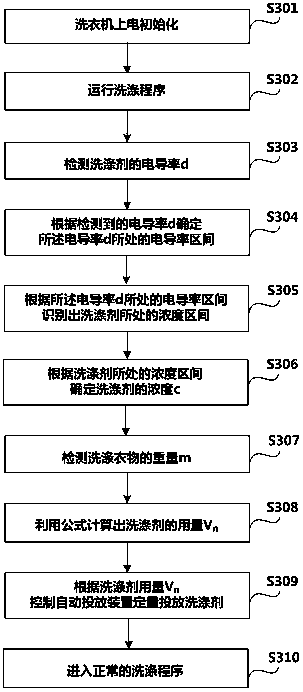

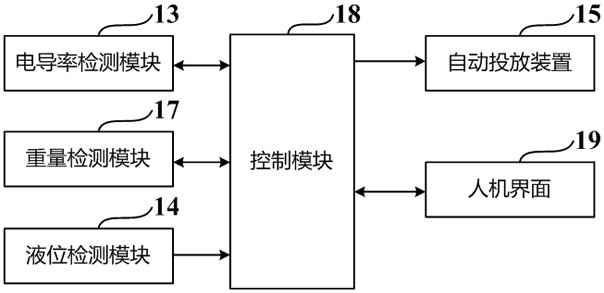

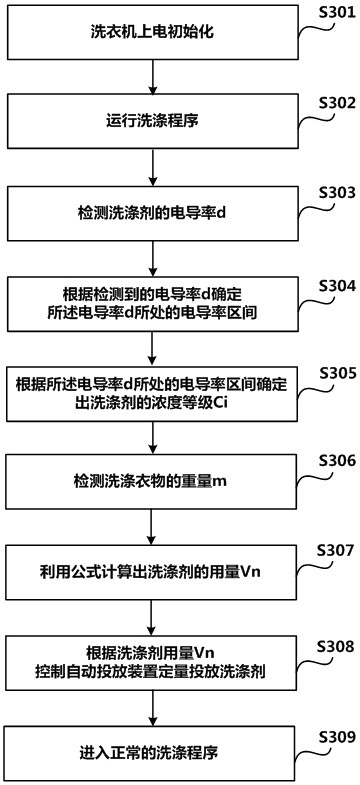

Precise detergent dosage control method and washing machine

InactiveCN109208233ASolve residual problemsSolve the increase of bubblesOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention discloses a precise detergent dosage control method and a washing machine. The method comprises steps that the concentration c of a detergent is obtained; the weight m of the laundry isobtained; a formula Vn=m*V0*(c0 / c)*Kc is utilized, the detergent dosage Vn is calculated, wherein, c0=15%, V0 is the dosage of the detergent with the concentration of 15% for washing 1 kg of the laundry, and Kc is a constant. The method is advantaged in that two factors of the detergent concentration and the laundry weight are comprehensively considered, the detergent dosage is determined throughformula calculation, so precise control of the detergent dosage is realized, a problem that the concentrated detergent is excessively applied when the detergent dosage is determined based on the weight of the laundry is solved, and problems of detergent residue, increased foams, multiple rinsing and water and electricity waste due to excessive detergent delivery are solved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Waste water valve

InactiveCN108708980AReduce processing costsRealize smart deliveryOperating means/releasing devices for valvesValve members for heating/coolingWastewaterDrive motor

The invention discloses a waste water valve. The waste water valve comprises a valve body. The valve body is internally provided with a left-right interlinked water passing groove. The left end face of the valve body is fixedly provided with a water inlet pipe. The water inlet pipe is internally provided with a water inlet groove communicating with the water passing groove. The right end face of the valve body is fixedly provided with a water outlet pipe. The water outlet pipe is internally provided with a water outlet groove communicating with the water passing groove. The bottom wall of thewater passing groove is provided with a first sliding groove in a communication manner, and the first sliding groove extends downwards. The first sliding groove is internally provided with a valve plate in a sliding manner. The valve plate is internally provided with an internal thread groove with a downward opening. The internal thread groove is internally provided with a threaded rod in a threadfit manner. The lower end of the threaded rod is in power connection with a drive motor which is fixedly installed in the bottom wall of the first sliding groove. The top wall of the water passing groove is internally provided with a second sliding groove communicating with the water passing groove. The second sliding groove is internally provided with an extensible and retractable plate in a sliding manner. The extensible and retractable plate is internally provided with a first oblique groove. The right side of the second sliding groove is provided with a material cavity with an upward opening.

Owner:PUJIANG ZHIYIN TECH CO LTD

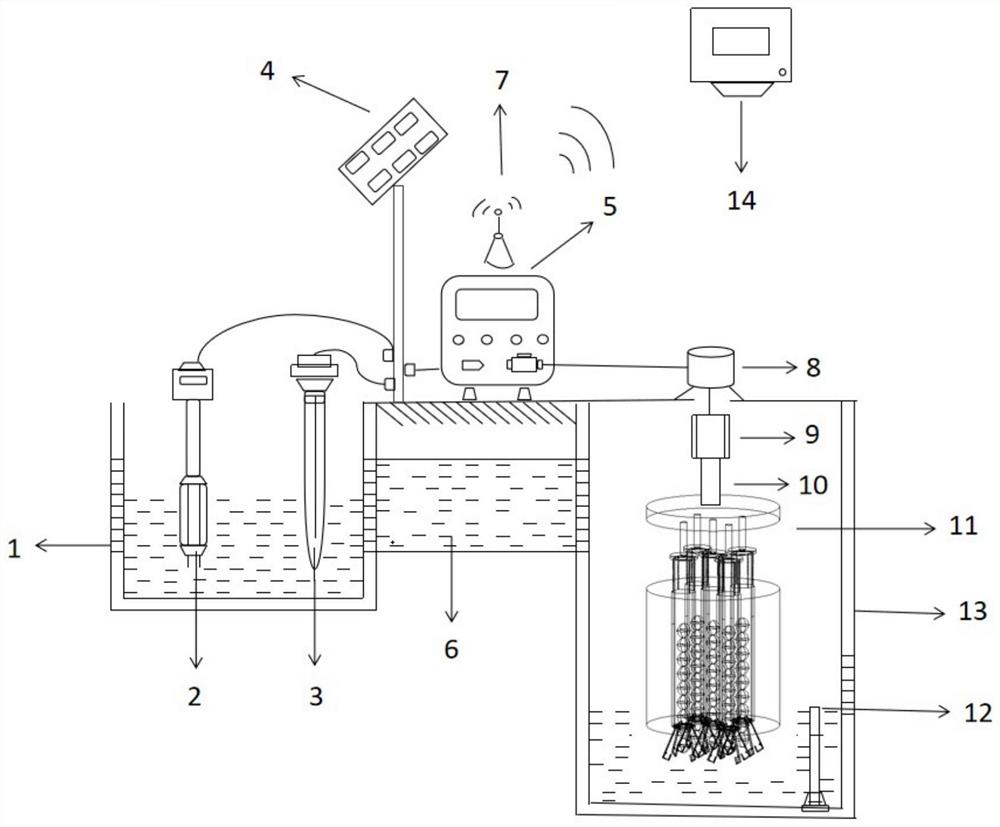

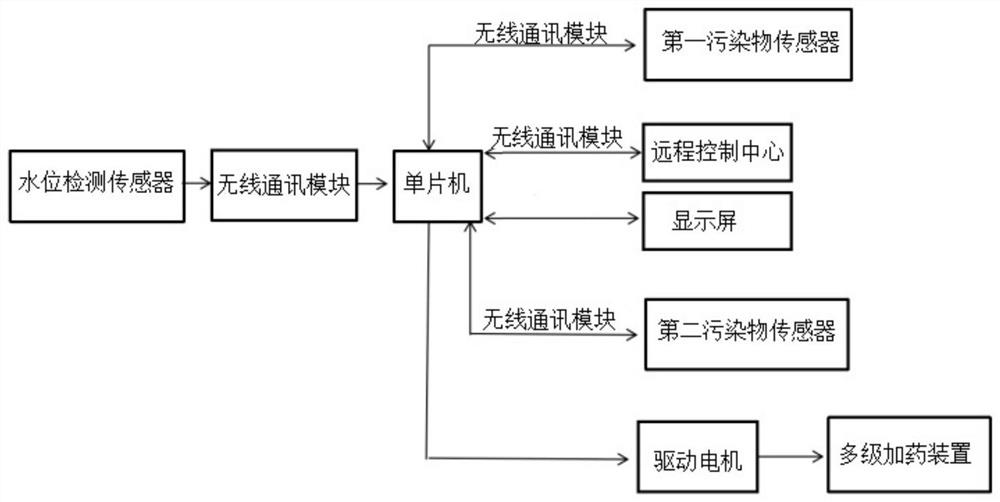

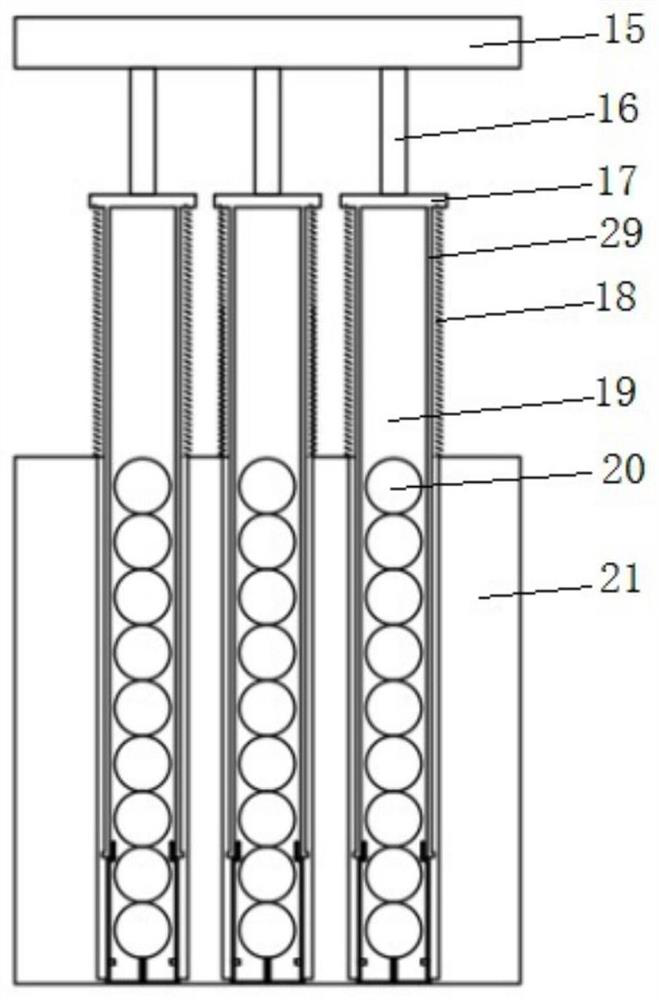

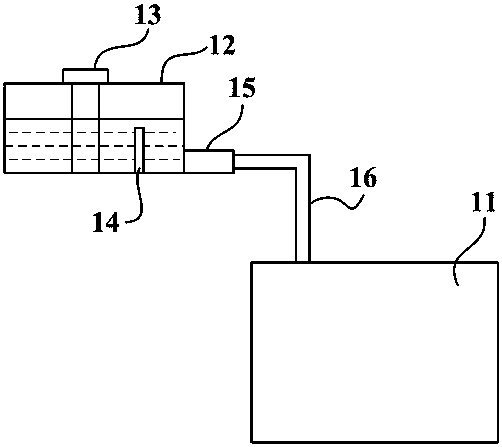

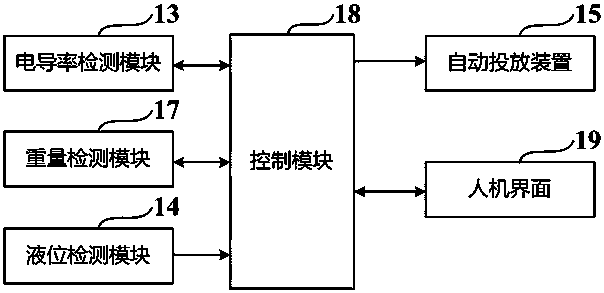

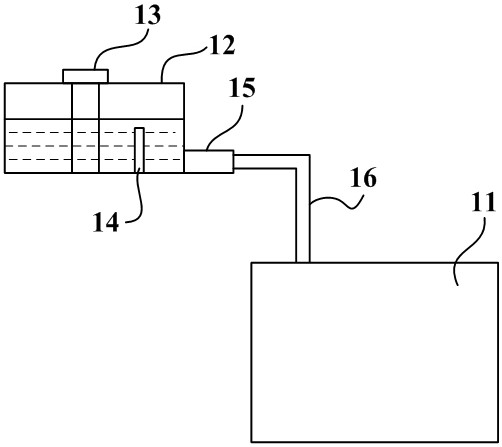

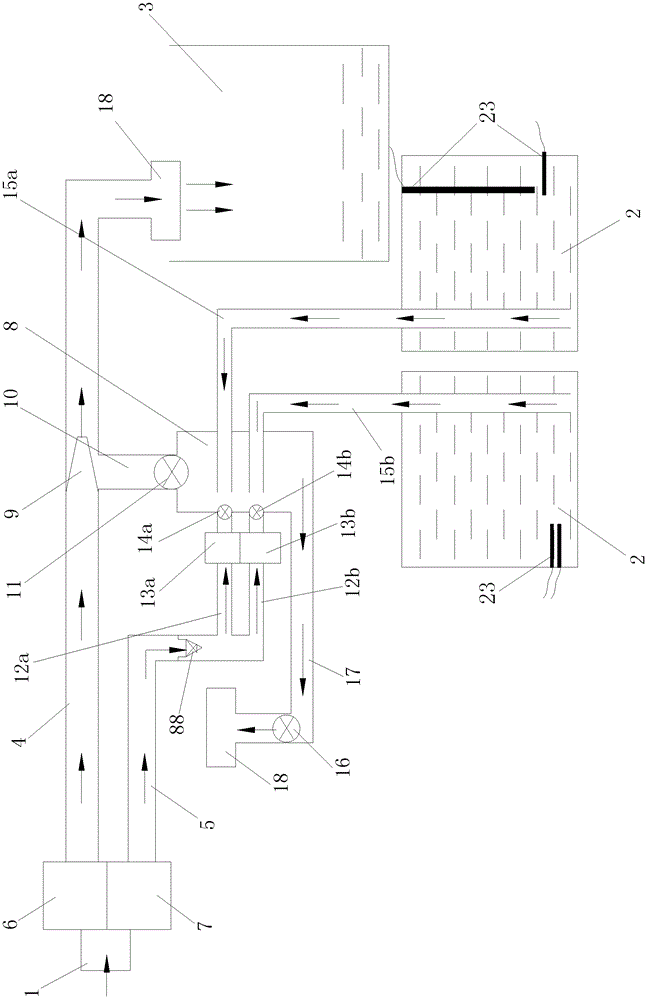

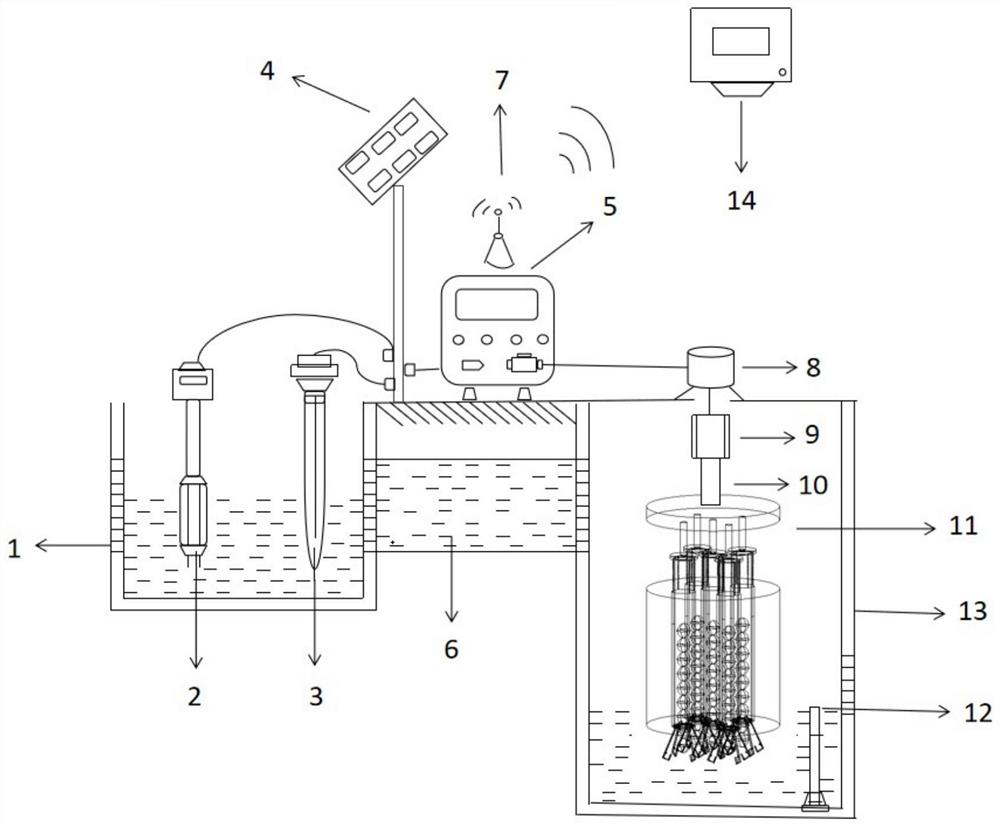

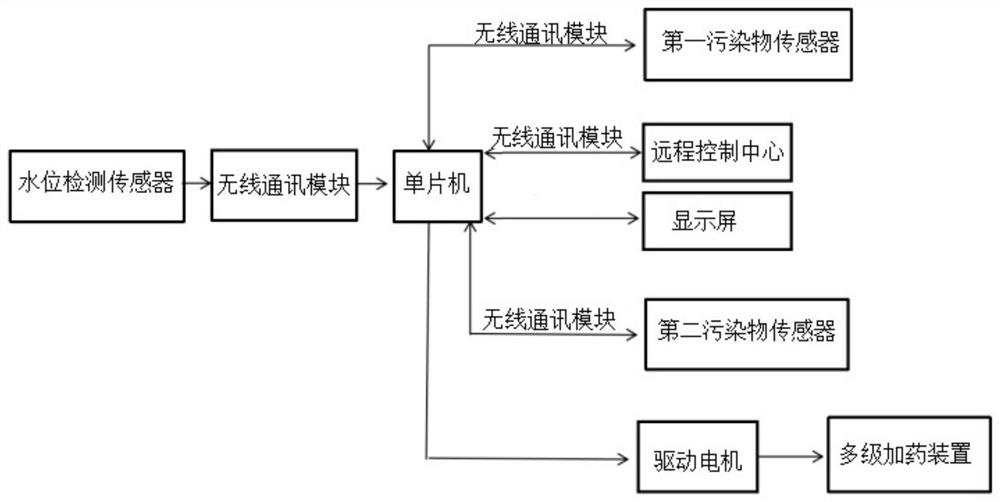

Underground water quality detecting and repairing system and method

ActiveCN112062172AImprove delivery accuracyAvoid overdeliveryWater treatment parameter controlGeneral water supply conservationDosing FrequencyWater quality

The invention discloses an underground water quality detecting and repairing system and method, wherein a pollutant sensor is adopted to detect and monitor the components and concentration of underground water pollutants in a restoration pool, and the dosage and dosing frequency of each dosing of a dosing device are strictly controlled according to the components and concentration, so that the restoration efficiency is improved, the dosing precision of a medicament is greatly improved, and excessive dosing of the medicament is avoided. According to the invention, the system is of a detecting and repairing integrated structure, manual participation is not needed in the whole detecting and repairing process, the intelligent degree is high, the control accuracy of the feeding amount is high,excessive feeding of chemicals can be avoided through the design of the chemical feeding device, the repairing cost is reduced, and the repairing efficiency is improved.

Owner:POWERCHINA ZHONGNAN ENG +1

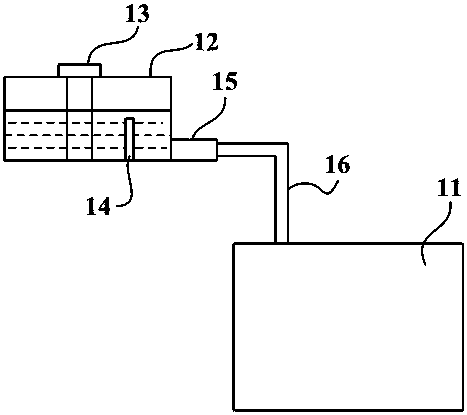

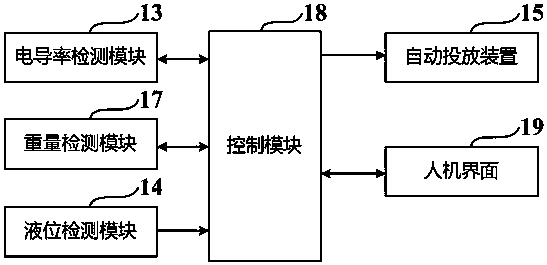

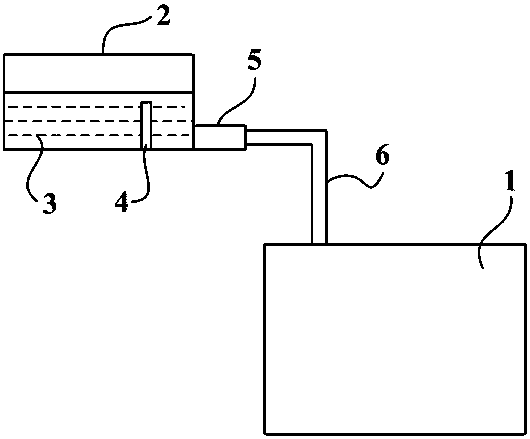

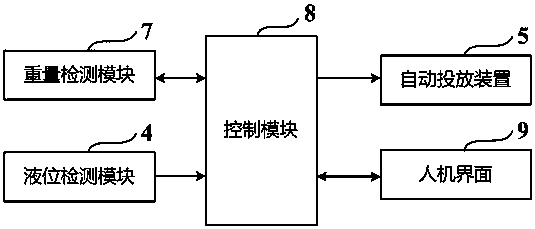

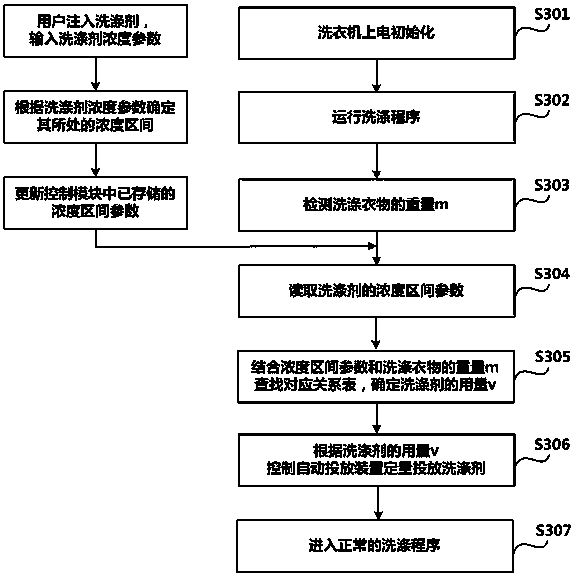

Method for determining detergent dosage according to detergent concentration and washing machine

InactiveCN109208235AAvoid overdeliverySolve residual problemsOther washing machinesControl devices for washing apparatusChemistryLaundry

The invention discloses a method for determining the detergent dosage according to the detergent concentration and a washing machine. The method is characterized in that externally-inputted detergentconcentration parameters are received by the washing machine; the concentration interval in which the detergent concentration parameters are located is determined according to the detergent concentration parameters; according to the concentration interval in which the detergent concentration parameters are located in combination with the weight of the laundry, the detergent dosage is determined through looking up a correspondence table. Through setting a detergent concentration parameter manual input interface on a man-machine interface of the washing machine, a user can manually input the concentration parameters identified on a detergent outer package into the washing machine, the concentration interval of the detergent is determined by the washing machine through user input, a weight detecting module disposed on the washing machine is further utilized to sense the weight of the laundry, the detergent dosage is comprehensively determined through combination of the detergent concentration and the laundry weight, so precise control of the detergent delivery dosage is realized, and problems of foam residue caused by over delivery, multiple rinsing and water and electricity waste canbe solved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Automatic feeding device for dairy cow feeding

The invention discloses an automatic feeding device for dairy cow feeding, and belongs to the field of dairy cow feeding, the automatic feeding device comprises a bottom plate, the bottom plate is provided with a feeding trough, a barrier and a guide rail, the barrier is provided with a plurality of feeding holes, the upper side of the feeding trough is slidably provided with a discharging box, and the discharging box is internally provided with a discharging mechanism; the upper side of the discharging box is connected with a crushing box, a crushing mechanism is arranged in the crushing box and driven by a crushing motor, a sliding frame is fixed to the lower side of the crushing box, and the bottom of the sliding frame is arranged in a guide rail; and the upper side of the crushing box is connected with the feeding box. According to the device, automatic moving and feeding can be achieved, the feeding process is high in efficiency, when bundled forage is fed, the forage can be compressed and crushed through the crushing mechanism, the forage can be smoothly fed, the device is prevented from being blocked, discharging of the forage is achieved along with moving of the device, when the device stops, feeding of the forage can be stopped, and the feeding efficiency is improved. Therefore, forage waste is avoided.

Owner:连云港东旺奶牛养殖有限公司

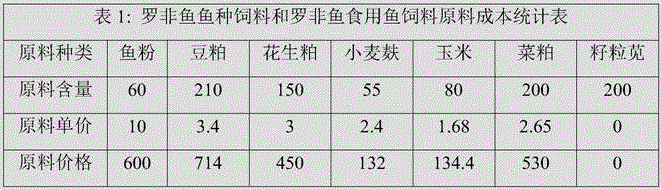

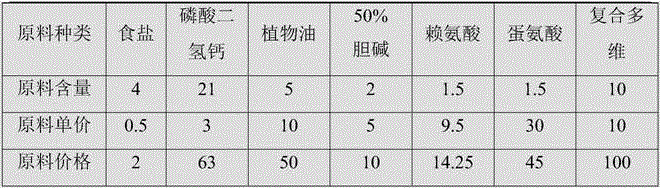

Feeding method for tilapia mossambica

InactiveCN106719153AGood for healthDemand adaptationFood processingClimate change adaptationTilapiaFeeding Methods

The invention relates to the field of fish feeding, and particularly relates to a feeding method for tilapia mossambica. The feeding method comprises the following steps that a. fingerlings of tilapia mossambica and a fish-feeding pond are selected, and then the fingerlings of tilapia mossambica are put into the fish-feeding pond; b. the tilapia mossambica fingerling feed is thrown into the fish-feeding pond and c. when the fingerlings of tilapia mossambica grow to the juvenile stage, the tilapia mossambica feed is thrown into the fish-feeding pond. The feeding method for tilapia mossambica has the advantages that the cost is low, the water is not polluted during the feeding process and the disease resistance of tilapia mossambica can be increased to promote healthy growth of tilapia mossambica.

Owner:GUANGDONG ZHONGMEI AGRI TECH CO LTD

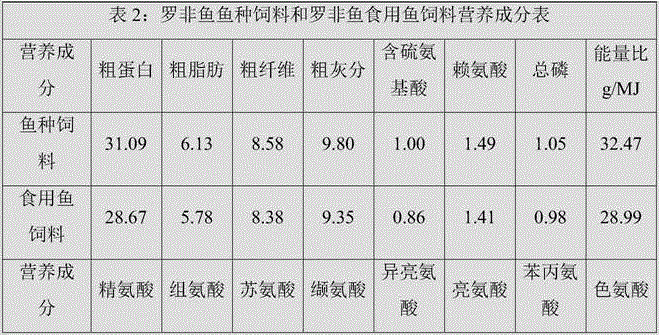

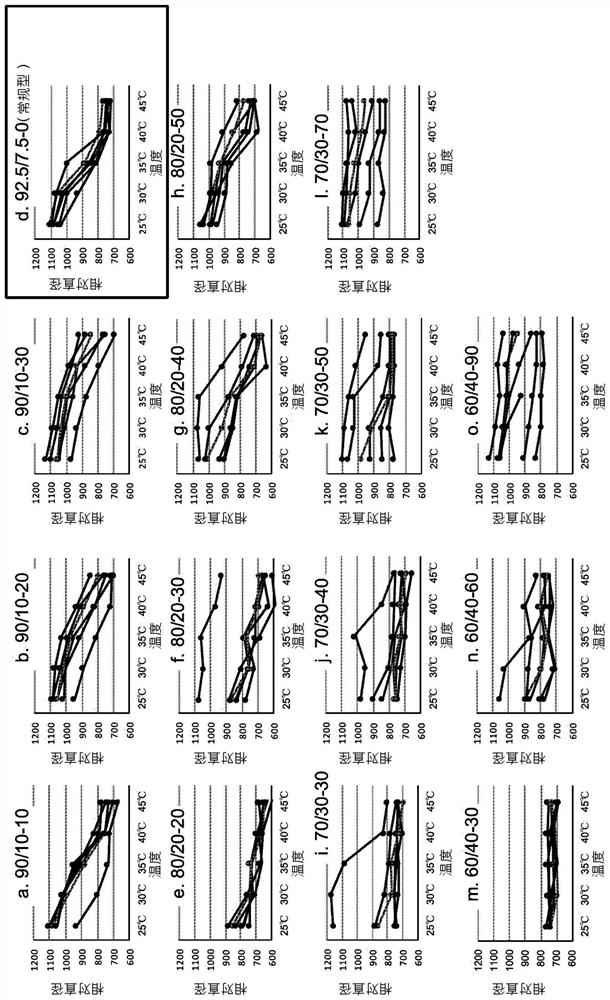

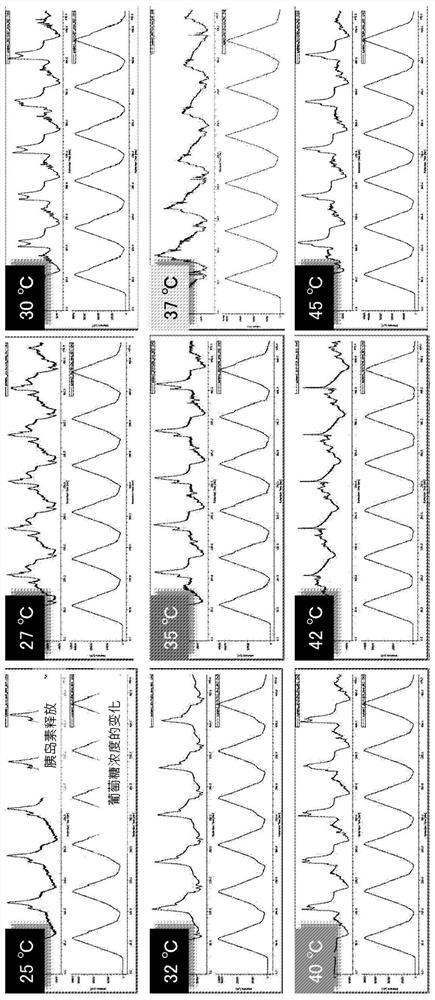

Temperature-resistant sugar-responsive gel

PendingCN112236170AImprove temperature resistanceAvoid overdeliveryPeptide/protein ingredientsMetabolism disorderPharmaceutical drugSugar

The present invention provides a sugar-responsive gel that is highly resistant to temperature changes, and a sugar-responsive drug delivery device including such a gel. The sugar-responsive gel, whichcomprises a gel composition including a monomer having a hydroxyl group in addition to a phenylboronic-acid-based monomer, can exhibit suitable temperature resistance. A sugar-responsive drug delivery device including such a sugar-responsive gel is less susceptible to the effects of temperature changes, and therefore can prevent undesirable excessive delivery of a drug (such as insulin) even if the body temperature of a patient wearing the device has dropped for any reason.

Owner:NAT UNIV CORP TOKAI NAT HIGHER EDUCATION & RES SYST +2

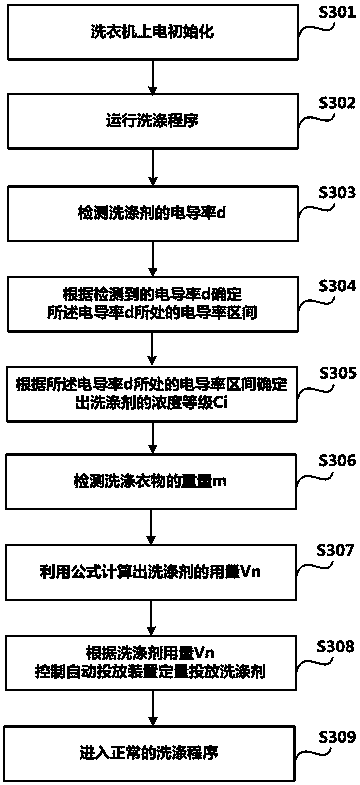

Precise detergent dosage control method and washing machine

InactiveCN109208263ASolve detergent residueAvoid overdeliveryOther washing machinesControl devices for washing apparatusWater costLaundry

The invention discloses a precise detergent dosage control method and a washing machine. The method comprises steps that N concentration intervals are established in order from low to high; each concentration interval is assigned with a concentration level, the i-th concentration interval corresponds to the i-th concentration level, Ci=N-i+1, and i=1,... ..., and N; the concentration level Ci of the detergent in a washing apparatus is determined; the weight m of the laundry is obtained; a formula Vn=1.25*m* (Ci + 1) is utilized, and the dosage Vn of the detergent is obtained through calculation. The method is advantaged in that two factors of detergent concentration and washing clothes weight are comprehensively considered, the detergent dosage is determined through formula calculation, soprecise control of the detergent dosage is realized, a problem that the concentrated detergent is excessively applied when the detergent dosage is determined based on the weight of the laundry is solved, and problems of detergent residue, increased foams, multiple rinsing and water and electricity waste due to excessive detergent delivery are solved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

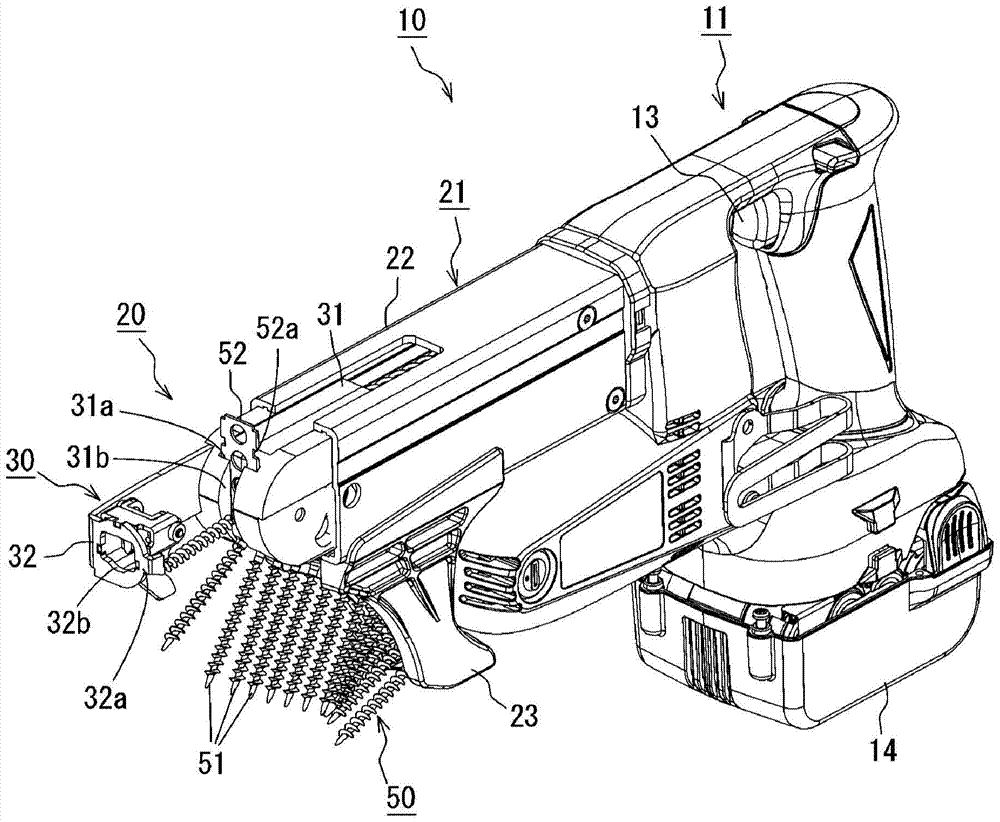

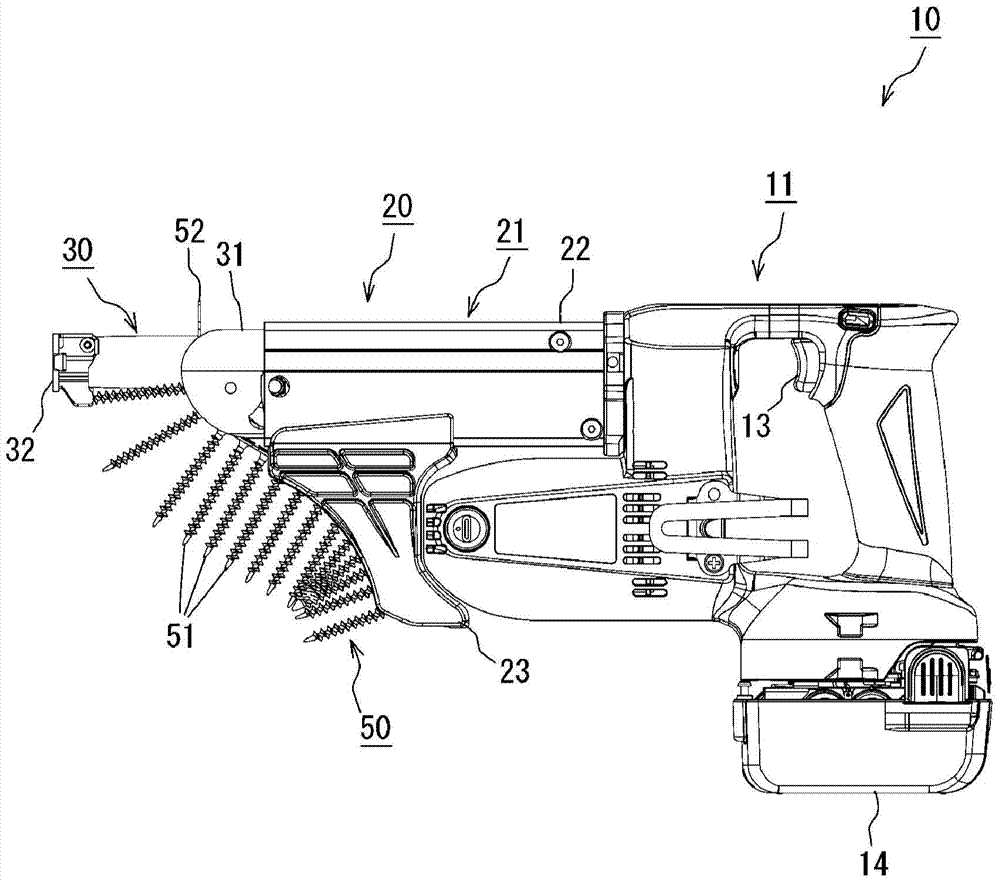

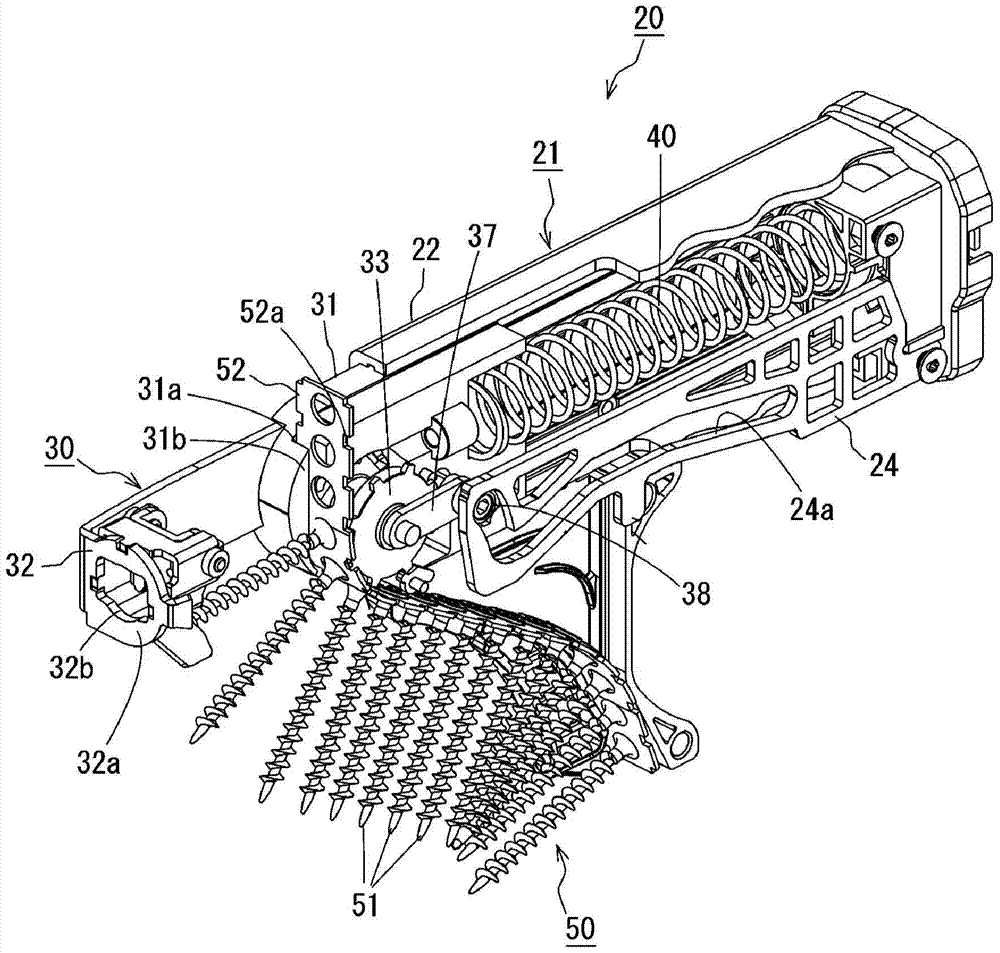

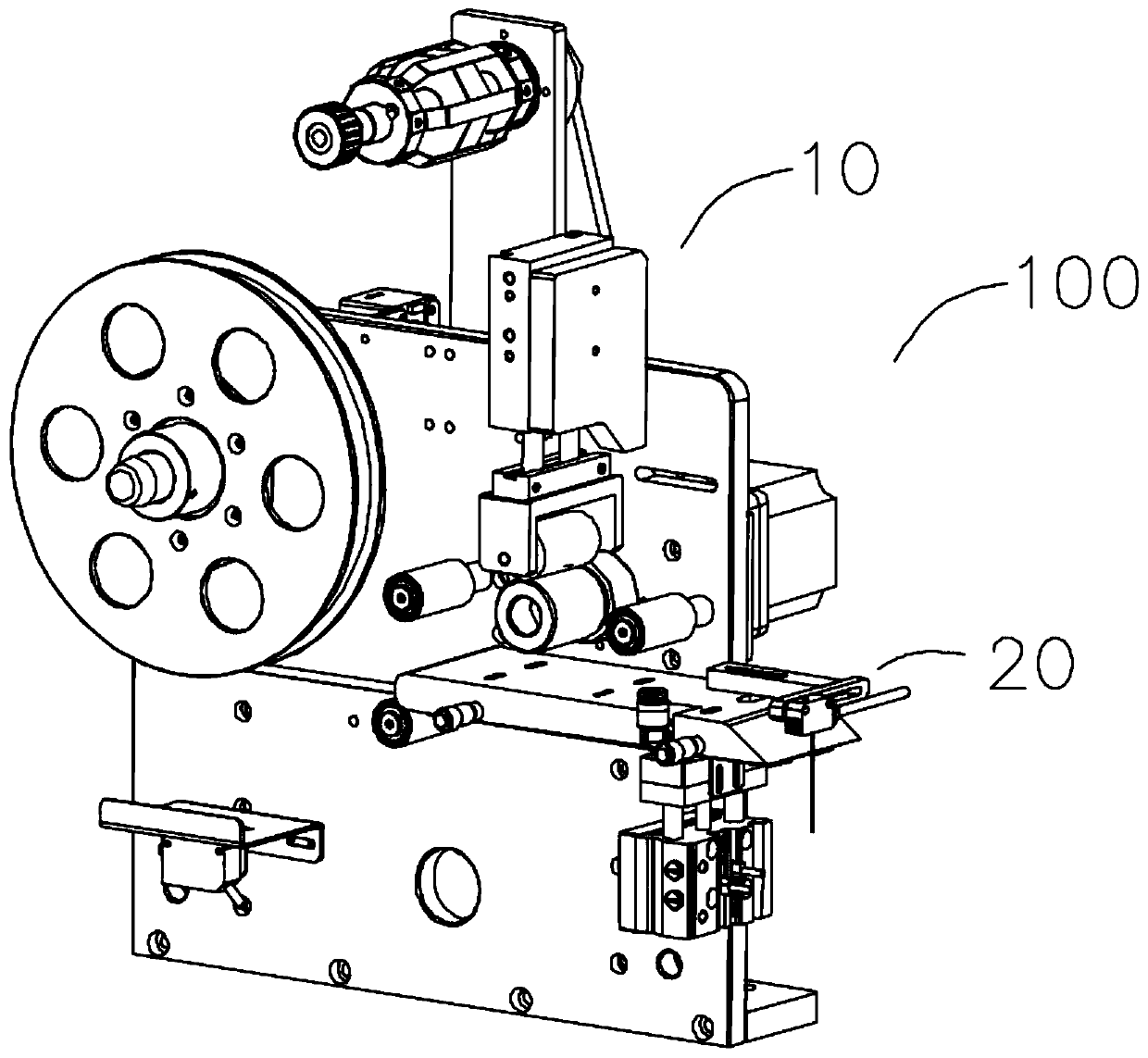

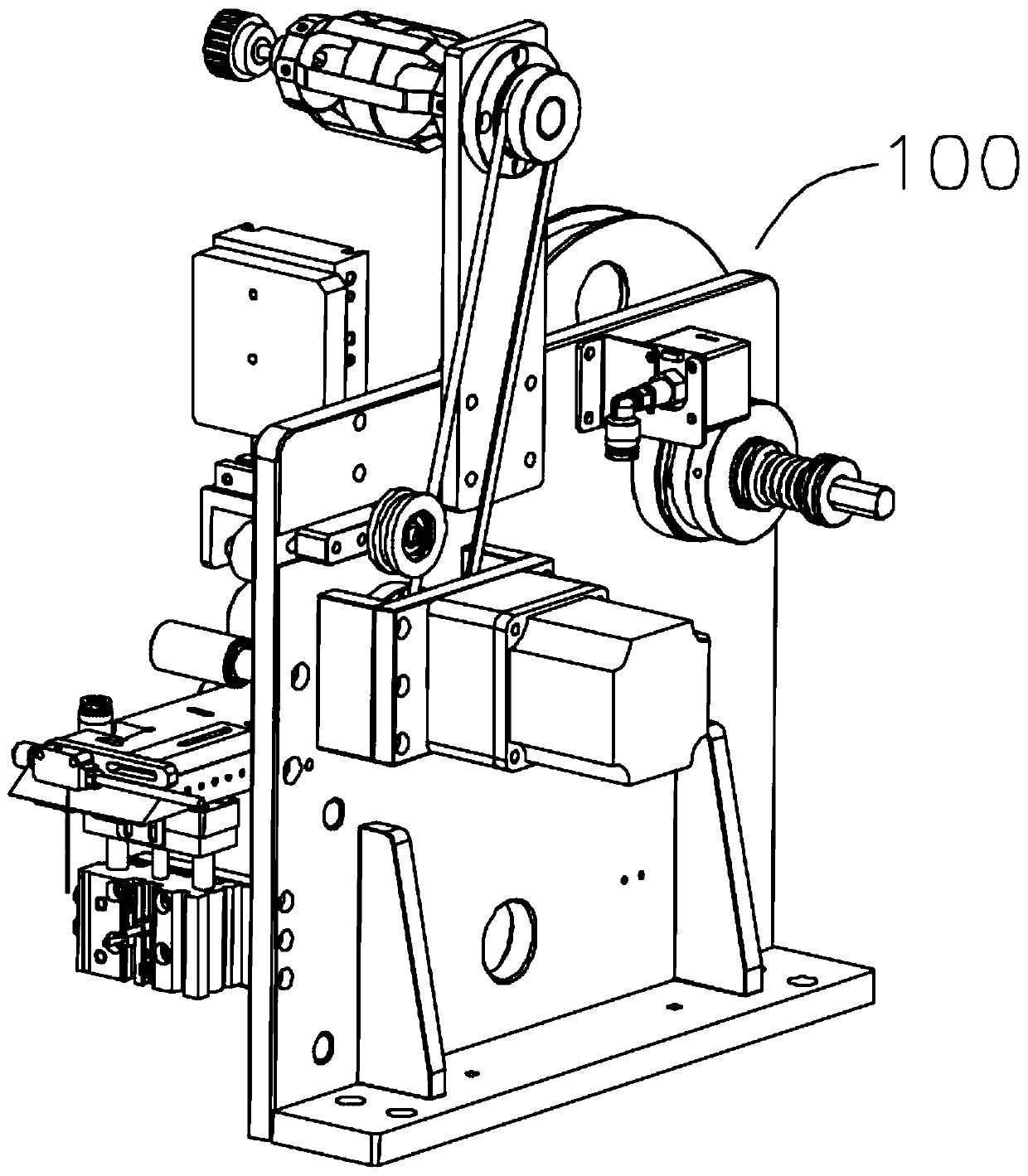

Screw guide structure in screwdriver for connecting screws

A screw guide structure of a screw feeding mechanism of a screw driver (10) is provided. The screw feeding mechanism is configured to sequentially feed collated screws (50) to a driving position. The collated screws (50) are plurality of screws (51) connected by a connecting band (52). The screw guide structure includes a base part (24), a nose member (30) provided on a distal end of the base part (24) in a slidable manner, and a straight-driving guide member (41) supported by the nose member (30) in a displaceable manner so as to guide a screw (51) fed by the screw feeding mechanism to be in a straight posture. The straight-driving guide member (41) has a concave guide groove (41b) configured to guide a shaft (51a) of the screw (51). The straight-driving guide member (41) is configured and arranged such that the shaft (51a) of the screw (51) is engaged into the guide groove (41b) when the screw (51) is fed by the screw feeding mechanism, and such that the straight-driving guide member (41) is displaced when a head (51b) of the screw (51) passes by driving the screw (51) engaged into the guide groove (41b).

Owner:MAX CO LTD

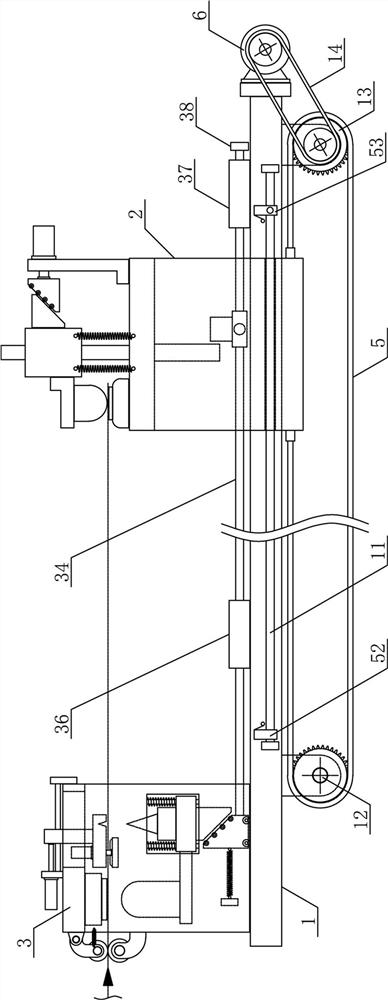

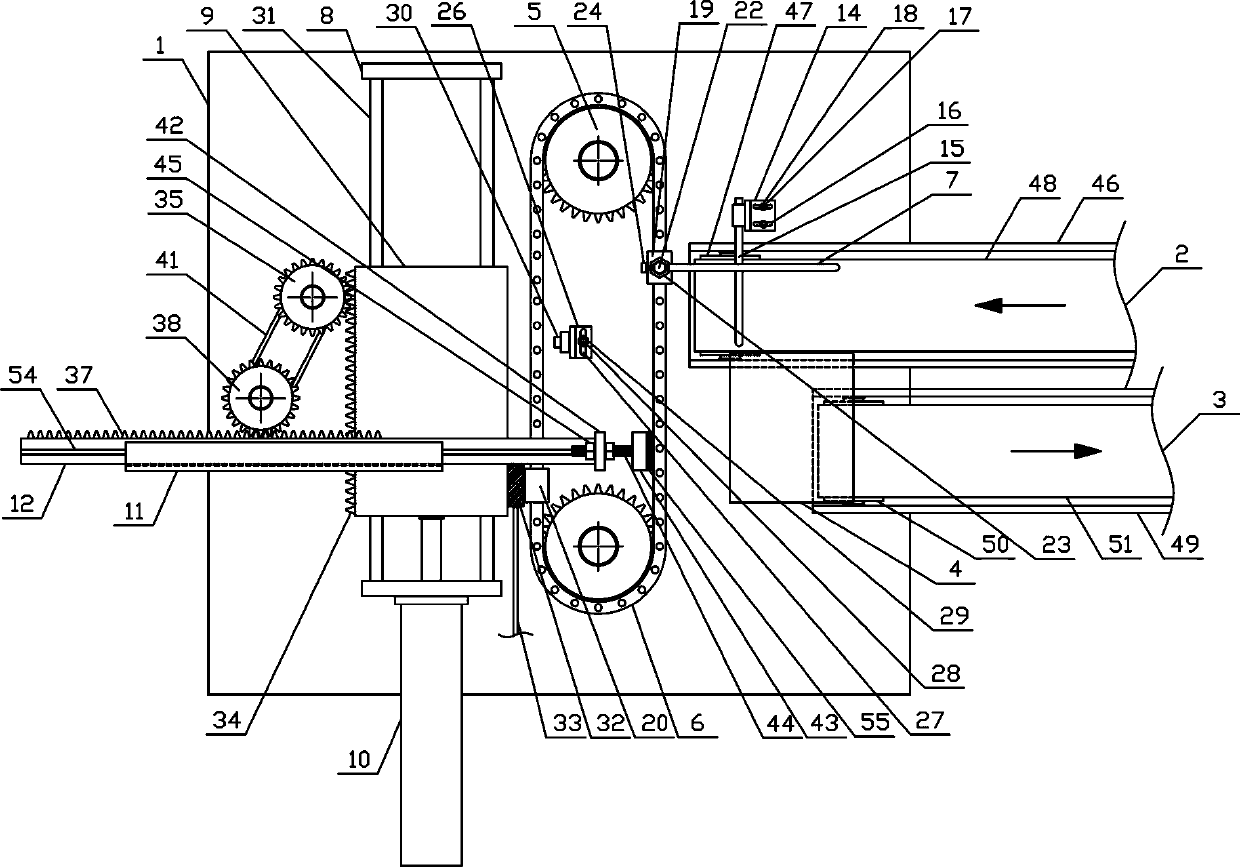

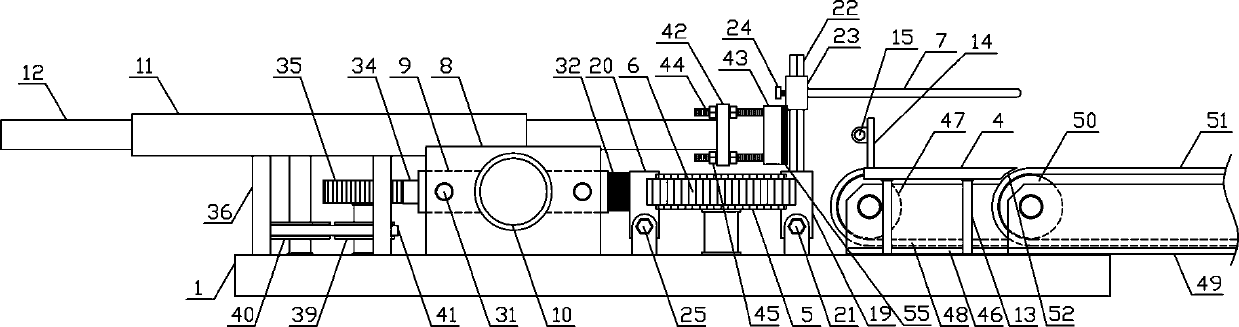

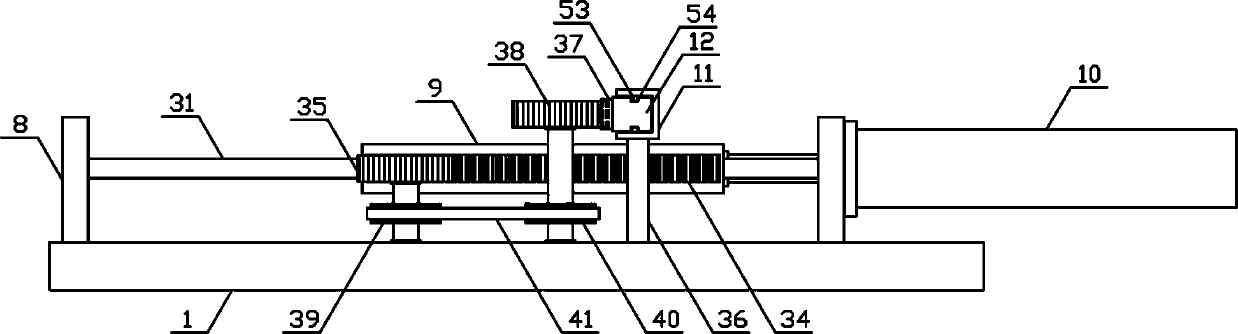

A workpiece automatic reversing conveying mechanism

ActiveCN108455251BRealize automatic reversing transmissionAvoid overdeliveryConveyor partsEngineeringMechanical equipment

The invention discloses a conveying mechanism with an automatic workpiece reversing function, and belongs to the field of mechanical conveying equipment for workpiece machining. According to the conveying mechanism with the automatic workpiece reversing function, a front conveying mechanism body and a rear conveying mechanism body are horizontally and fixedly arranged on the upper side of a fixedbased in sequence in the horizontal direction, and the two sides of a reciprocating chain are separately connected with two pushing chain wheels; a transverse moving electromagnet is horizontally andfixedly arranged on one side of a transverse moving guide plate, and a driving rack plate is arranged on the other side of the transverse moving guide plate in the horizontal direction; a pushing support is parallel to the conveying direction of the rear conveying mechanism body; and a horizontal pushing guide plate is slidably arranged on the pushing support in the horizontal direction, and a pushing rack plate is horizontally arranged on one side of the horizontal pushing guide plate. The conveying mechanism with the automatic workpiece reversing function is reasonable in structural design,workpieces which are sequentially conveyed along the front conveying mechanism body can be flatly pushed onto the rear conveying mechanism body rapidly and efficiently one by one so as to be conveyed,automatic reversing of the workpieces is realized, the machining efficiency and quality of the workpieces are improved, and production and use requirements are met.

Owner:湖南创一智能科技有限公司

Bianstone anti-freckle skin care product and preparation method thereof

ActiveCN105078843BPromote detoxificationPromote absorptionCosmetic preparationsToilet preparationsAcupunctureGlycerol

The invention discloses a meteorite-removing freckle skin care product and a preparation method thereof, and relates to the field of skin care products. The skin care product comprises 1-5 parts of polyacrylic acid / C13-14 isoparaffin / trideceth-6, 5-15 1-5 parts of glycerin, 1-5 parts of polydimethylsilane, 1-5 parts of meteorite powder, 1-5 parts of tourmaline powder, 0.1-0.3 parts of water-soluble curcumin, 0.1-3 parts of tocopheryl acetate, 0.1-3 parts Hydrolyzed whey protein / oat amino acids, 0.5-5 parts of beet root extract, 0.5-6 parts of jujube extract, 0.1-1 part of essence, and the balance is pure water or mineral water. The invention can continuously whiten, not only has low cost, but also can keep the skin in a healthy state.

Owner:HUBEI MULAN TONGDA TECH

Mariculture equipment with feed recycling bin

ActiveCN108575862BAvoid wastingImprove survival rateClimate change adaptationPisciculture and aquariaMarine aquacultureEngineering

The invention discloses seawater aquaculture equipment equipped with a feed recovery cylinder, which includes a cylindrical culture box for breeding, and the bottom of the culture box is separated by a partition plate to separate the feed recovery cylinder; it also includes a material distribution mechanism for feeding feed, and the material distribution mechanism The upper part is connected to the mixing box through the transmission pipe, and the upper part of the mixing box is connected to the feeding hopper; one side of the feed recovery cylinder is connected to a water delivery pump, and the other side is connected to a collection pipe, and the collection pipe is connected to a liquid suction pump. The equipment of the present invention It can effectively solve the problem of the turbidity of the breeding water and cause the death of the cultured animals, effectively improve the survival rate of the cultured animals, and the feeding of the feed can be controlled and the feed can be recycled.

Owner:金华市凌特水产养殖技术有限公司

A method for accurately controlling the amount of detergent and washing machine

ActiveCN109208232BAvoid overdeliveryOther washing machinesControl devices for washing apparatusLaundry washing machineProcess engineering

The invention discloses a method for accurately controlling the amount of detergent and a washing machine, comprising: establishing N concentration intervals in order from low to high; assigning a concentration level to each of the concentration intervals, and the i-th concentration The interval corresponds to the i-th concentration level Ci=i, i=1, ..., N, N<7; determine the concentration level Ci of the detergent in the washing machine; obtain the weight m of the laundry; use the formula Vn=1.25*m* (7‑Ci), calculate the amount of detergent Vn. The present invention comprehensively considers the two factors of detergent concentration and laundry weight, and adopts the formula calculation method to determine the amount of detergent, thus realizing the precise control of the amount of detergent, which can effectively avoid the easy occurrence of determining the amount of detergent according to the weight of clothes The problem of excessive use of concentrated detergent solves the problems of detergent residue, increased foam, multiple rinses, and water and electricity consumption caused by excessive use.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +2

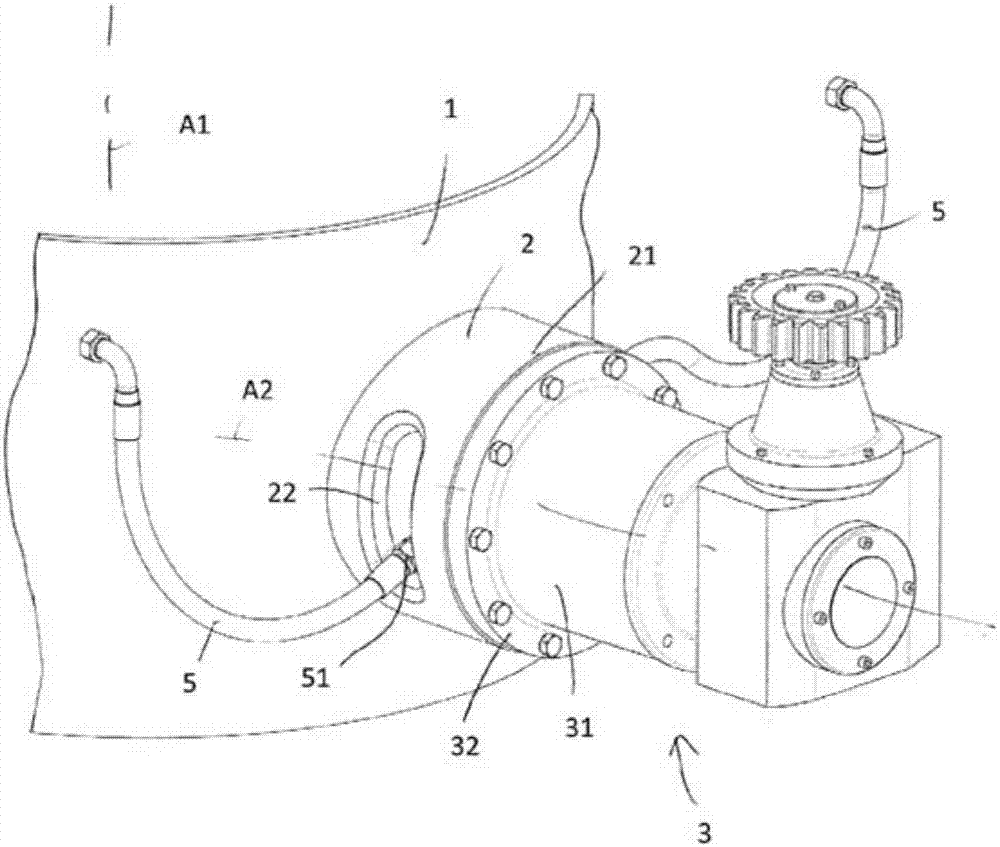

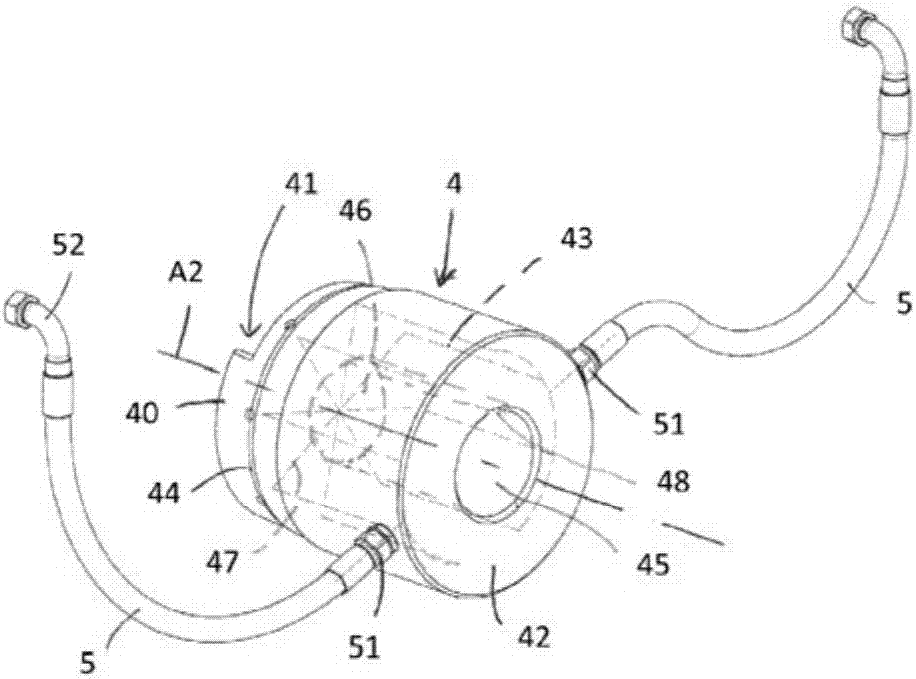

Device for cooling a shaft furnace distribution chute support journals

ActiveCN107076516AAvoid overdeliveryImprove cooling effectBell-and-hopper arrangementCooling devicesCouplingHorizontal axis

Device for cooling the support journals (4) of a distribution chute of an installation for charging a shaft furnace, such as a blast furnace, the chute being mounted with the ability to pivot about a horizontal axis (A2) on a ring (1) coaxial with the furnace, the chute being connected in rotation to the journals which are rotated by drive means, being for example connected directly in terms of rotation via their ends (42) to output shafts of reduction gear (3) and comprising internal cooling ducts (43). The cooling device comprises feed and return pipes (5) for the cooling water circulating through the internal ducts, the feed and return pipes (5) being connected to the journals (4) by couplings (51) fixed to the cylindrical surface of the journals, and the feed and return pipes (5) are designed to allow the rotary movement of the couplings (51) about the axis of pivoting of the chute when the chute pivots, notably by passing through oblong slots (22) extending circumferentially in the wall of bearings (2) supporting the driving reduction gear.

Owner:PAUL WURTH SA

Garment packaging equipment for garment production

ActiveCN113371256BFacilitate functioningAvoid overdeliveryPackagingElectrostatic chargesLaundryMechanical engineering

Owner:南通寝尚纺织品有限公司

Electrolyte conveying device for microelectronic processing

PendingCN111952225AAchieve entryAchieve separationSemiconductor/solid-state device manufacturingQuadrupole fieldElectrolytic agent

The electrolyte conveying device for microelectronic processing comprises a shell, a conveying cavity is formed in the shell, a liquid conveying channel is formed in the shell, the liquid conveying channel is arranged on one side of the conveying cavity in a V shape, two liquid inlets are fixedly formed in the side wall of one side of the shell. The two liquid inlets are correspondingly communicated with one end of the liquid conveying channel, a converging opening is fixedly formed in the side wall of the side, close to the liquid conveying channel, of the conveying cavity, and the convergingopening is correspondingly communicated with the end, away from the liquid inlets, of the liquid conveying channel. Magnetic liquid with a stable quadrupole magnetic field is used as a liquid pipe wall, and a water-based microfluid channel is constructed; that is to say, the water-based microfluid flows under the surrounding of the immiscible magnetic liquid, so that the interaction between the fluid and the pipe wall is greatly reduced, almost no friction exists, the liquid pipe wall can be self-cured, no blocking risk exists, and the valve opening and closing control function can be conveniently achieved.

Owner:朱言文

Special valve for wastewater

InactiveCN108730541AReduce processing costsRealize smart deliveryOperating means/releasing devices for valvesSlide valveDrive motorEngineering

The invention discloses a special valve for wastewater. The special valve comprises a valve body, wherein a water passing slot which is in left-right communication is formed in the valve body; the left end surface of the valve body is fixedly equipped with a water inlet tube; a water inlet slot which communicates with the water passing slot is formed in the water inlet tube; the right end surfaceof the valve body is fixedly equipped with a water outlet tube; a water outlet slot which communicates with the water passing slot is formed in the water outlet tube; the bottom wall of the water passing slot is equipped with a first slide slot which extends downwards in a communication mode; a valve plate is mounted in the second slide slot in a sliding mode; an inner threaded slot with a downward opening is formed in the valve plate; a threaded rod is mounted in the inner threaded slot in a threaded fit mode; the lower end of the threaded rod is in power connection with a drive motor fixedlymounted in the bottom wall of the first slide slot; a second slide slot which communicates with the water passing slot is formed in the top wall of the water passing slot; a telescopic plate is mounted in the second slide slot in a sliding mode; a first inclined slot is formed in the telescopic plate; and a material cavity with an upward opening is arranged at the right side of the second slide cavity.

Owner:PUJIANG ZHIYIN TECH CO LTD

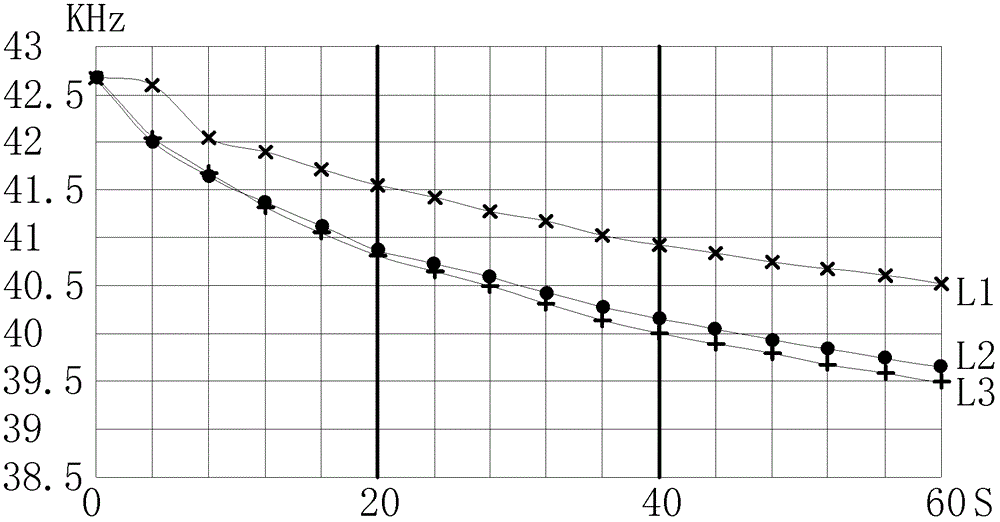

Method for judging the feeding time of automatic detergent feeding system and washing machine

ActiveCN102517850BAvoid overdeliveryRuntime ImprovementsOther washing machinesControl devices for washing apparatusEngineeringLow-pressure area

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Dish-washing machine distributor

PendingCN112790716AEasy to useAvoid wastingTableware washing/rinsing machine detailsProcess engineeringIndustrial engineering

The invention provides a dish-washing machine distributor, and belongs to the technical field of dish-washing machines. The dish-washing machine distributor solves the technical problem that an existing detergent adding device for the dish washing machine does not have a solid detergent and liquid detergent compatible mode. The dish-washing machine distributor comprises a dish-washing machine door body, a detergent storage box and an adding device, and is characterized in that the detergent storage box and the adder are both arranged on the dish-washing machine door body, a detergent storage cavity and a brightener storage cavity are formed in the detergent storage box, a conveying structure used for conveying detergent is further arranged on the detergent storage box, the adding device is provided with a detergent inlet and a brightener inlet, the adding device is further provided with a solid storage box, the detergent inlet is communicated with the detergent storage cavity, and the brightener inlet is communicated with the brightener storage cavity. The dish-washing machine distributor has the advantage of being good in use effect.

Owner:MARSSENGER KITCHENWARE CO LTD

System and method for detecting and repairing groundwater quality

ActiveCN112062172BImprove delivery accuracyAvoid overdeliveryWater treatment parameter controlGeneral water supply conservationDrug dosingWater quality

The invention discloses a system and method for detecting and repairing groundwater quality. A pollutant sensor is used to detect and monitor the composition and concentration of groundwater pollutants in a repairing pool, and the dosage and dosing of a dosing device are strictly controlled according to the composition and concentration. The number of times improves the repair efficiency, greatly improves the accuracy of drug delivery, and avoids excessive drug delivery; the system is an integrated structure for detection and repair, and does not require manual participation during the entire detection and repair process. It is highly intelligent and the dosage is controlled High precision, the design of the dosing device can avoid excessive dosage of medicine, reduce the repair cost and improve the repair efficiency.

Owner:POWERCHINA ZHONGNAN ENG +1

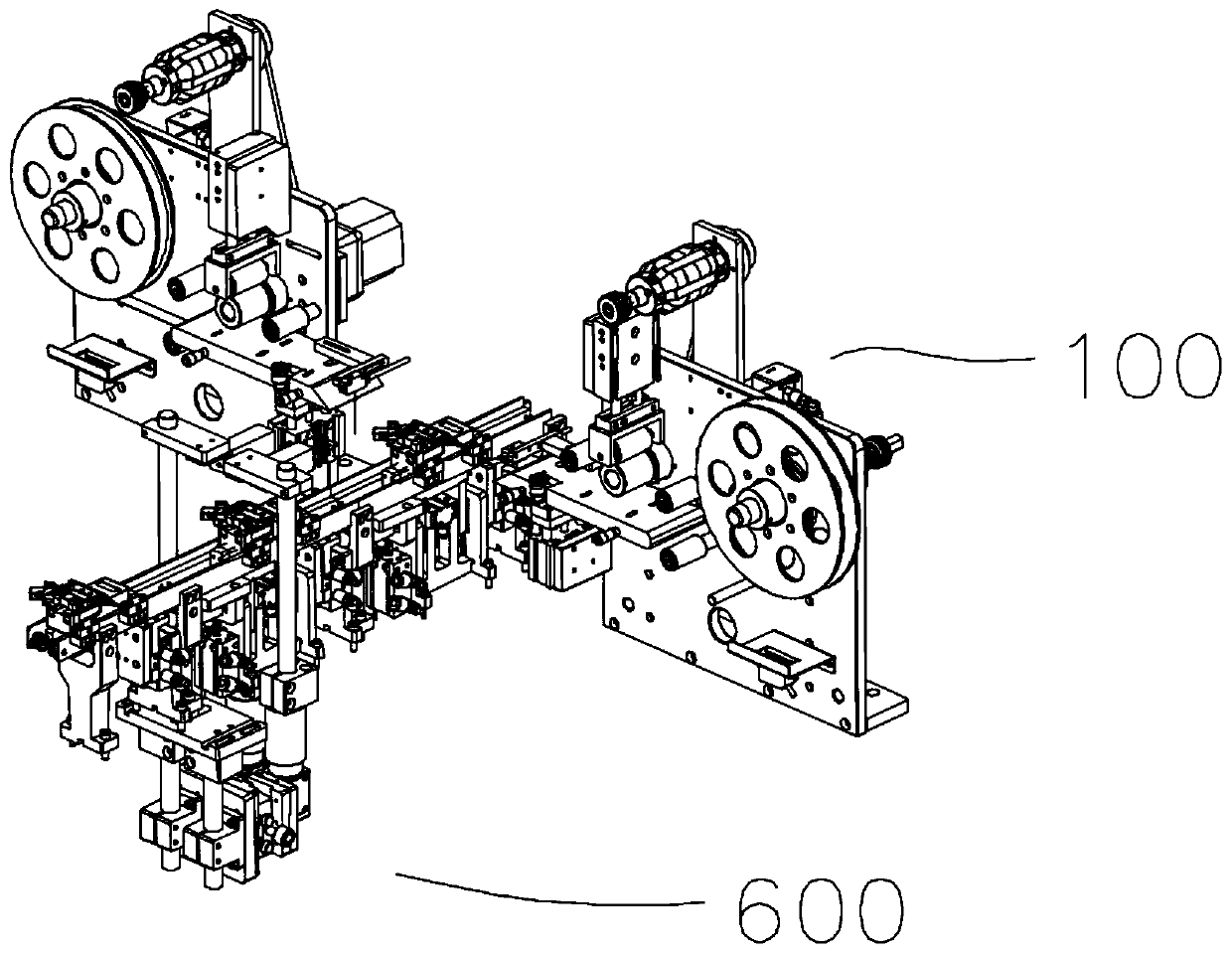

Stripping and shooting mechanism

PendingCN109866990AAvoid overdeliveryHigh positioning accuracyLabelling machinesEngineeringLeather belt

The invention discloses a stripping and shooting mechanism. The stripping and shooting mechanism comprises a stripping mechanism and a shooting mechanism; the stripping mechanism comprises a winding mechanism and a stripping and pressing mechanism; the stripping and pressing mechanism comprises a stripping main body; the shooting mechanism comprises a position detecting mechanism and a front end belt module; the position detecting mechanism comprises a position detecting camera; the front end belt module comprises a conveying structure, a stabilizing frame, a stop structure and a positioning structure; the conveying structure comprises a side shielding piece, a conveying wheel and a belt; the stop structure comprises a stop cylinder and a stop piece; when fixtures are conveyed along a beltto reach a stop position in use, the stop cylinder drives the stop piece to move to stop the fixtures to prevent excessive conveying of the fixtures; and when the stop position is continuously shifted to reach a positioning position, a first side stop cylinder drives the side stop piece to move to stop from the left side, the stripping mechanism strips patches, and the position detecting camera is aligned to the patches on the fixtures, so that the masses and the positions of the patches are shot and detected, and the automation degree is high.

Owner:启翊创智能科技(苏州)有限公司

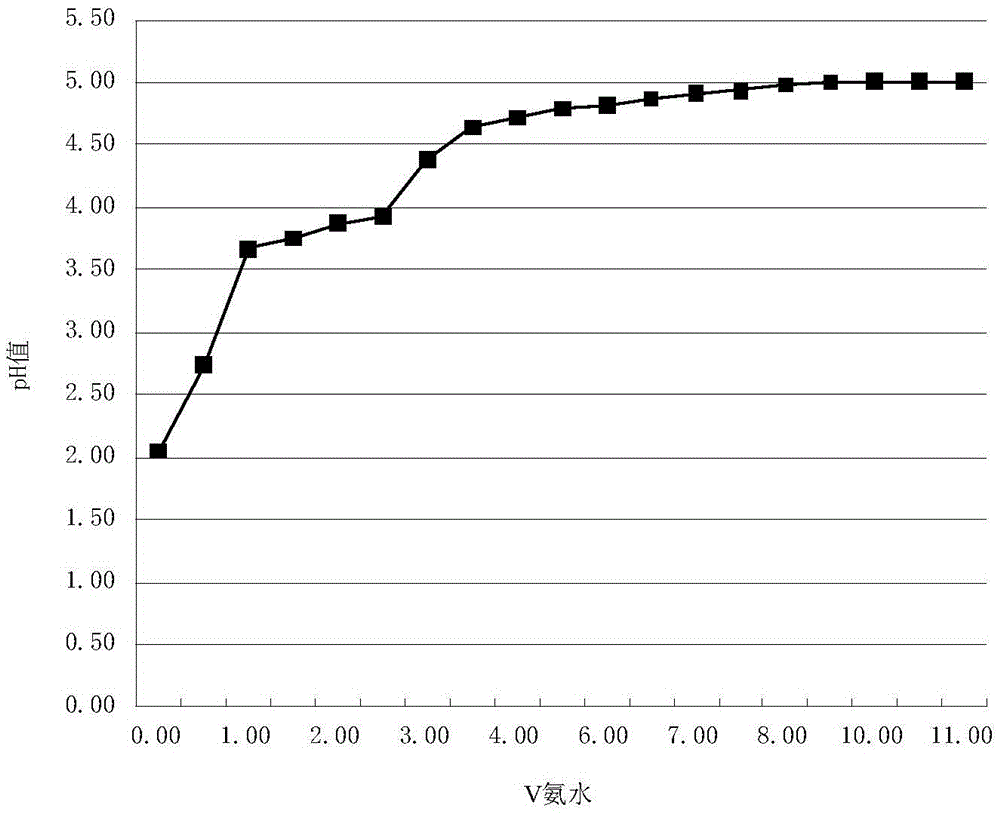

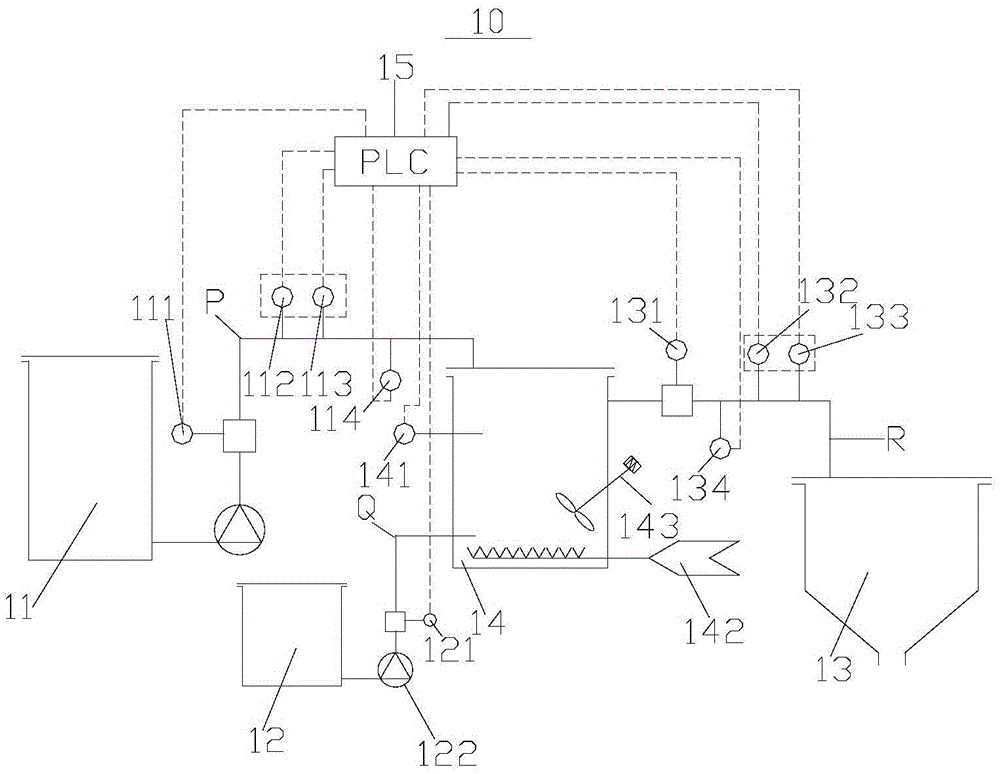

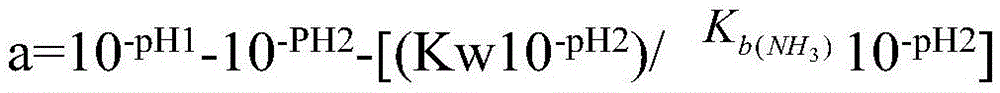

Method for controlling the addition amount of neutralizing agent ammonia in silicon removal neutralization reaction

ActiveCN104512865BControl delivery volumeThe delivery volume is reasonableWater treatment parameter controlChlorine/hydrogen-chloride purificationIron oxideFeedback control

The invention discloses a method for controlling the addition amount of ammonia water (neutralizing agent) in a silicon-moving neutralization reaction. The method comprises the following steps: according to the relationship between a waste acid pH value (pH2) after a silicon-moving neutralization reaction and a target pH value (pH target) of the silicon-moving neutralization reaction, carrying out feedback control of the addition amount of ammonia water (neutralizing agent): when pH2<=pH target, the addition amount (Y) of ammonia water is accord with a formula (shown in the description); when pH2>pH target, the addition amount (Y) of ammonia water is according with a formula (shown in the description). The provided control method can precisely control the addition amount of neutralizing agent to waste acid, thus the yield of Fe(OH)3 precipitation can be precisely controlled, the silicon-removing efficiency is guaranteed, the iron loss is maximally reduced, and the output of iron oxide red is increased.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com