Method for controlling the addition amount of neutralizing agent ammonia in silicon removal neutralization reaction

A control method and technology of addition amount, applied in the field of metallurgy to achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for controlling the amount of neutralizing agent ammonia added in the silicon removal and neutralization reaction described in the present invention will be further explained below in conjunction with specific embodiments, but the explanation does not constitute an improper limitation to the technical solution of the present invention.

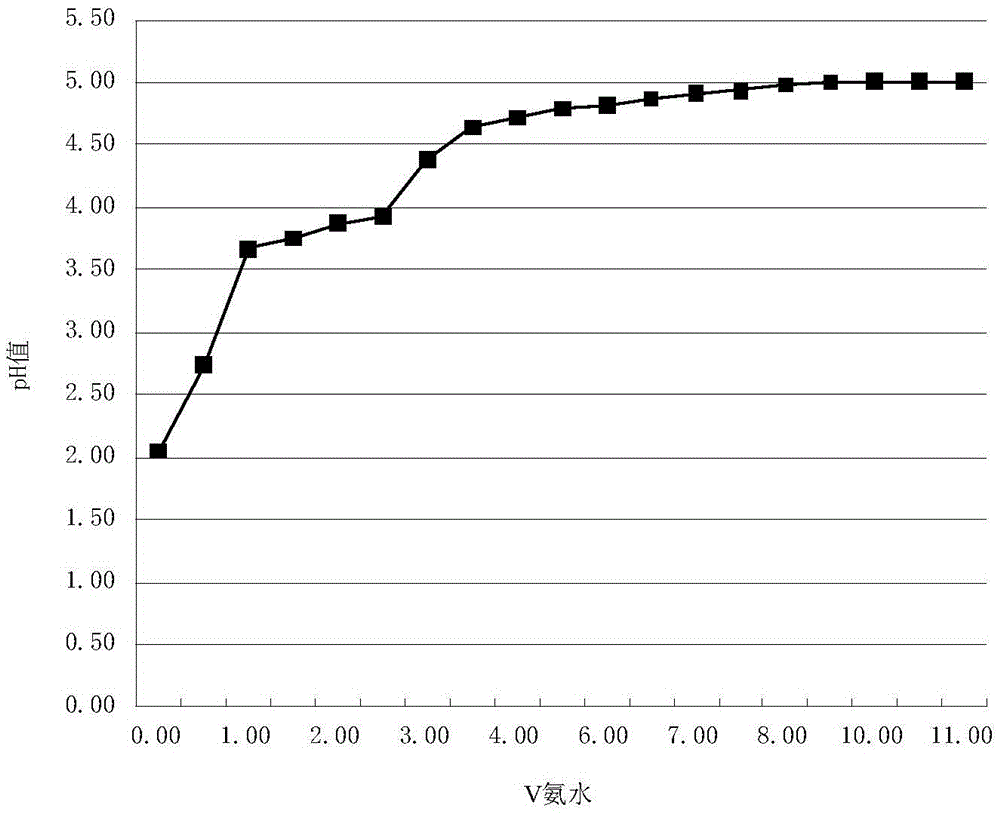

[0024] The inventors used the chemical titration method to measure the change relationship between the amount of ammonia water added and the pH value of the solution, so as to verify whether the pH value can accurately reflect the process and effect of the silicon removal and neutralization reaction. At room temperature, add a certain amount of ammonia water dropwise to the waste acid solution, and stir while adding dropwise, the pH value of the obtained solution varies with the amount of ammonia water added as follows: figure 1 shown.

[0025] From figure 1 It can be seen that when the ammonia water is just added to the pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com