Mariculture equipment with feed recycling bin

A technology for marine aquaculture and recycling cylinders, applied in fish farming, application, climate change adaptation and other directions, can solve the problems of affecting the respiration of aquaculture, water turbidity, feed waste, etc., to avoid excessive feeding of feed, delay the dissolution rate, The effect of reducing the hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

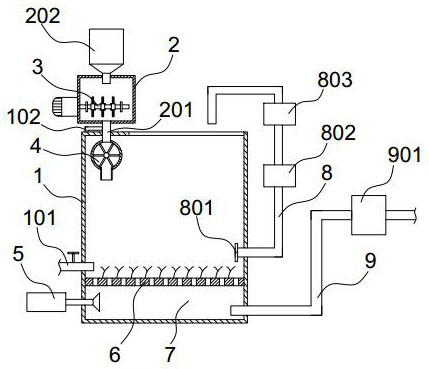

[0027] As shown in 1 and 5, the marine aquaculture equipment equipped with a feed recovery cylinder,

[0028] It includes a cylindrical breeding box 1 for breeding, and the bottom of the breeding box 1 is separated by a partition 6 with a feed recovery cylinder 7;

[0029] It also includes a distributing mechanism 4 for feeding feed, the top of the distributing mechanism 4 is connected to the mixing box 2 through the transmission pipe 201, and the upper part of the mixing box 2 is connected to the feeding hopper 202;

[0030] One side in the feed recovery cylinder 7 is connected with a water delivery pump 5, and the other side is connected with a collection pipe 9, and the collection pipe 9 is connected with a liquid suction pump 901, and the feed recovery cylinder 7 at the bottom of the breeding box 1 is used for breeding. Immediately ingested feed is recycled to avoid waste of feed, eutrophication of water body, humus, etc., and improve the transparency of water body to faci...

Embodiment 2

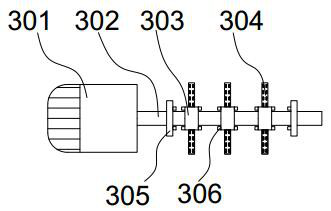

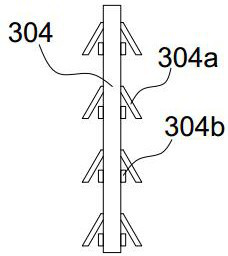

[0034] The further optimization scheme of this embodiment on the basis of embodiment 1 is as follows: Figure 2-4 As shown, a stirring mechanism 3 is horizontally arranged in the stirring box 2, and the stirring mechanism 3 includes a motor 301 connected to the outside of the stirring box 2. The rotating shaft 302 of the motor 301 is connected to the stirring box 2 horizontally, and the front and rear ends of the rotating shaft 302 are connected with limited positions. Block 305, slip ring 303 is movably connected on the rotating shaft 302 between the limiting blocks 305, slip ring 3 slips on the rotating shaft 302 and is limited by the limiting block 305 to slip in a certain area during the feed stirring process. Stirring the feed once can increase the compactness of the feed, reduce the hydrolysis rate of the feed, and delay the dissolution rate of the feed in the water after it is put into the water body, which is beneficial to the collection of the feed.

[0035] The surface...

Embodiment 3

[0039] When the mariculture equipment provided with the feed recovery cylinder of the present invention is actually used, the feed is put into the feed hopper 202, and the feed reaches the distribution mechanism after being processed by the mixing box 2, and the feeding speed of the feed is controlled by controlling the rotational speed of the runner 401 and the amount of input, the cultured animals in the breeding box 1 can ingest the feed when the feed sinks into the bottom of the breeding box 1 case to increase the activity of the cultured animals in the breeding box 1, which is beneficial to improve the survival rate of the cultured animals and improve the meat quality. The feed recovery cylinder 7 at the bottom of the breeding box 1 recycles the feed that is not ingested by the cultured animals immediately during the breeding process to avoid waste of feed, eutrophication of the water body, humus, etc., improve the transparency of the water body to facilitate observation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com