Surface source and backlight module employing same

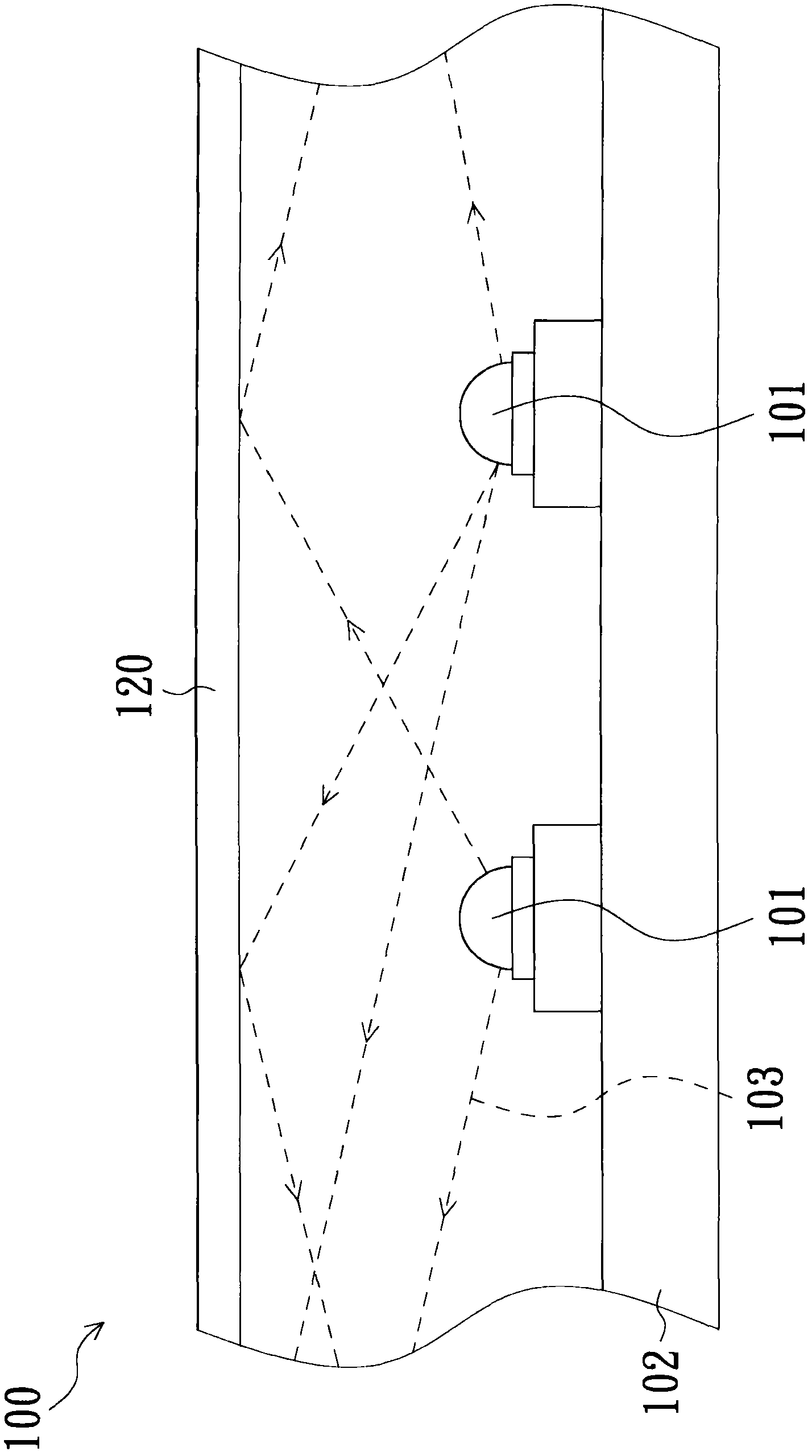

A technology of backlight module and surface light source, which is applied in the field of surface light source and can solve the problem of uneven light mixing of red, green and blue colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

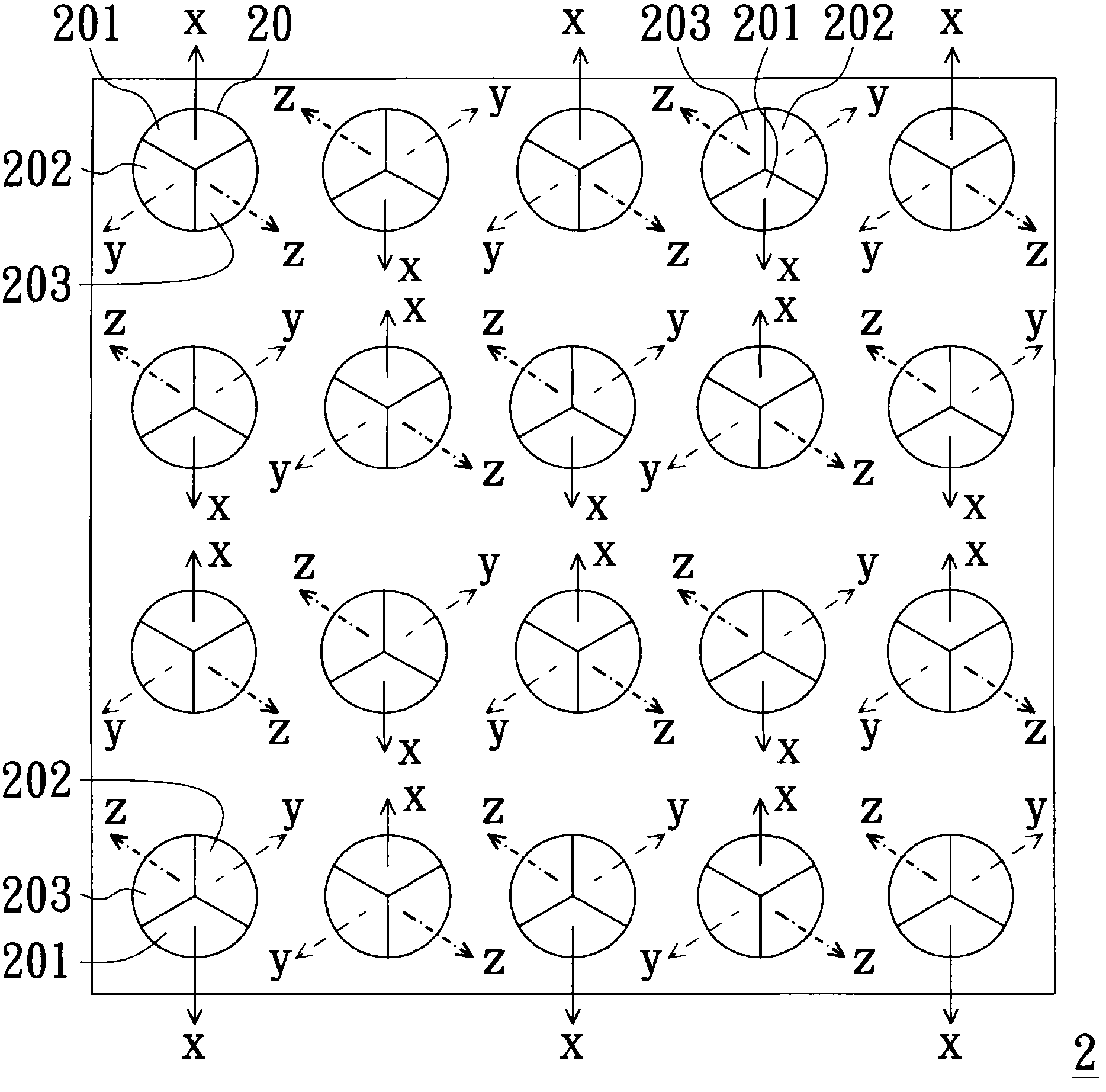

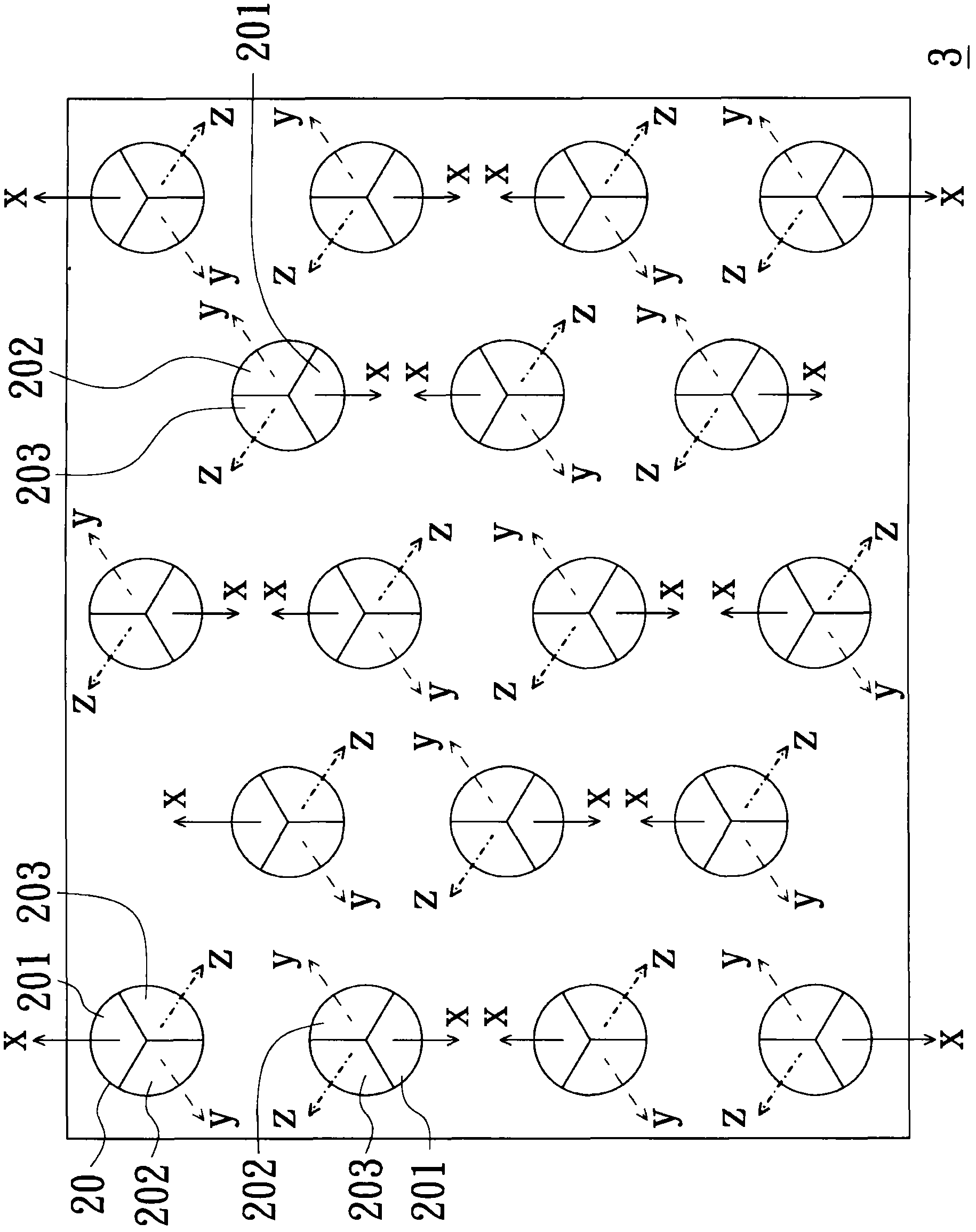

[0032] See figure 2 , which is a schematic diagram of a surface light source according to an embodiment of the present invention. Depend on figure 2 It can be seen that the surface light source 2 of this embodiment includes a plurality of LED packaging structures 20 arranged in a first matrix. Each LED packaging structure 20 includes a first color light emitting portion 201 , a second color light emitting portion 202 and a third color light emitting portion 203 . That is to say, the LED packaging structure 20 of this embodiment is, for example, packaging LEDs of three different colors into one package. Wherein, the first color light emitting portion 201 has a first light emitting axis X. The second color light emitting part 202 has a second light emitting axis Y, and the third color light emitting part 203 has a third light emitting axis Z. Specifically, the light emitted by the first color light emitting unit 201 is emitted approximately along the light emitting axis X,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com