Vehicular LED headlamp

A technology of LED lamp beads and headlights, which is applied in lighting devices, fixed lighting devices, lighting and heating equipment, etc., which can solve the problem of low light utilization rate, poor heat dissipation, and inability to form ideal high-beam or low-beam spots And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

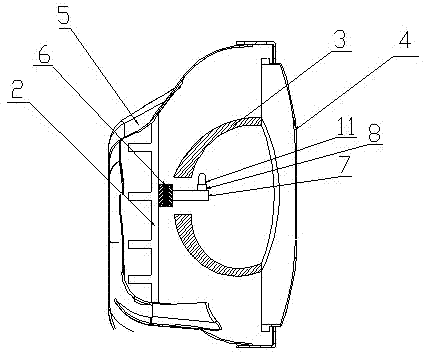

[0019] Embodiment one: if figure 1 , Figure 7 The shown vehicle LED headlamp (i.e. low beam) includes a first LED lamp bead 11, a radiator 2, a reflective bowl 3, a glass plate 4, a rear shell 5 and an electronic cooling chip 6, and the first LED lamp bead 11 is located in the reflective bowl 3. The reflective surface of the reflective bowl 3 is a parabolic surface as a reference surface. The paraboloid is divided into several areas, and the curvature and direction of each area are adjusted to form a free-form surface that meets the light distribution requirements of low beams. The light-emitting center of an LED lamp bead 11 is set on the focal point of the reference curved surface, with the mouth of the reflective bowl 3 facing forward as a reference, the setting direction of the first LED lamp bead 11 is that the light-emitting surface is upward, and the light emitted by the first LED lamp bead 11 All or most of the light falls on the reflective surface of the upper half ...

Embodiment 2

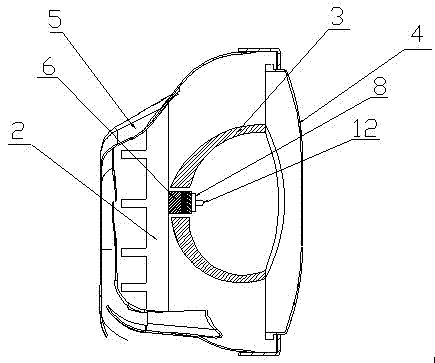

[0020] Embodiment two: if figure 2 , Figure 7 The vehicle LED headlamp shown (that is, the first high-beam lamp) includes a second LED lamp bead 12, a radiator 2, a reflective bowl 3, a glass plate 4, a rear shell 5 and an electronic refrigeration chip 6, and the second The LED lamp bead 12 is located in the reflective bowl 3. The reflective surface of the reflective bowl 3 is a paraboloid as a reference curved surface. The paraboloid is divided into several areas, and the curvature and direction of each area are adjusted to meet the high beam light distribution requirements. Curved surface, the luminous center of the second LED lamp bead 12 is set on the focal point of the reference curved surface, and the bowl mouth of the reflective bowl 3 is used as the reference, and the setting direction of the second LED lamp bead 12 is forward on the basis of the light emitting surface. Tilted at 90° (that is, facing the direction of the mouth of the reflective bowl), the light emit...

Embodiment 3

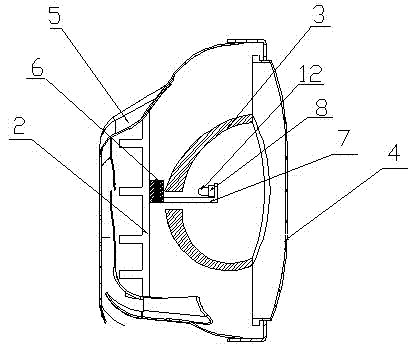

[0021] Embodiment three: as image 3 , Figure 7 The vehicle LED headlamp shown (that is, the second high-beam lamp) includes a second LED lamp bead 12, a radiator 2, a reflective bowl 3, a glass plate 4, a rear shell 5 and an electronic cooling chip 6, and the second The LED lamp bead 12 is located in the reflective bowl 3. The reflective surface of the reflective bowl 3 is a paraboloid as a reference curved surface. The paraboloid is divided into several areas, and the curvature and direction of each area are adjusted to meet the high beam light distribution requirements. Curved surface, the light-emitting center of the second LED lamp bead 12 is set on the focal point of the reference curved surface, with the bowl opening of the reflective bowl 3 as the reference, the setting direction of the second LED lamp bead 12 is backward on the basis of the light-emitting surface Tilted at 90° (that is, facing the direction of the bottom of the reflective bowl), the light emitted by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com