Automobile signal lamp LED electronic control module

An electronic control and signal light technology, applied in the field of automobile signal lights, can solve the problems of difficult to meet the lamp body shape design, the optical system light decay can not achieve the expected effect, and it is difficult to achieve standardization, so as to reduce the number of electronic components and reduce the number of components. Cost, effect of avoiding short circuit risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

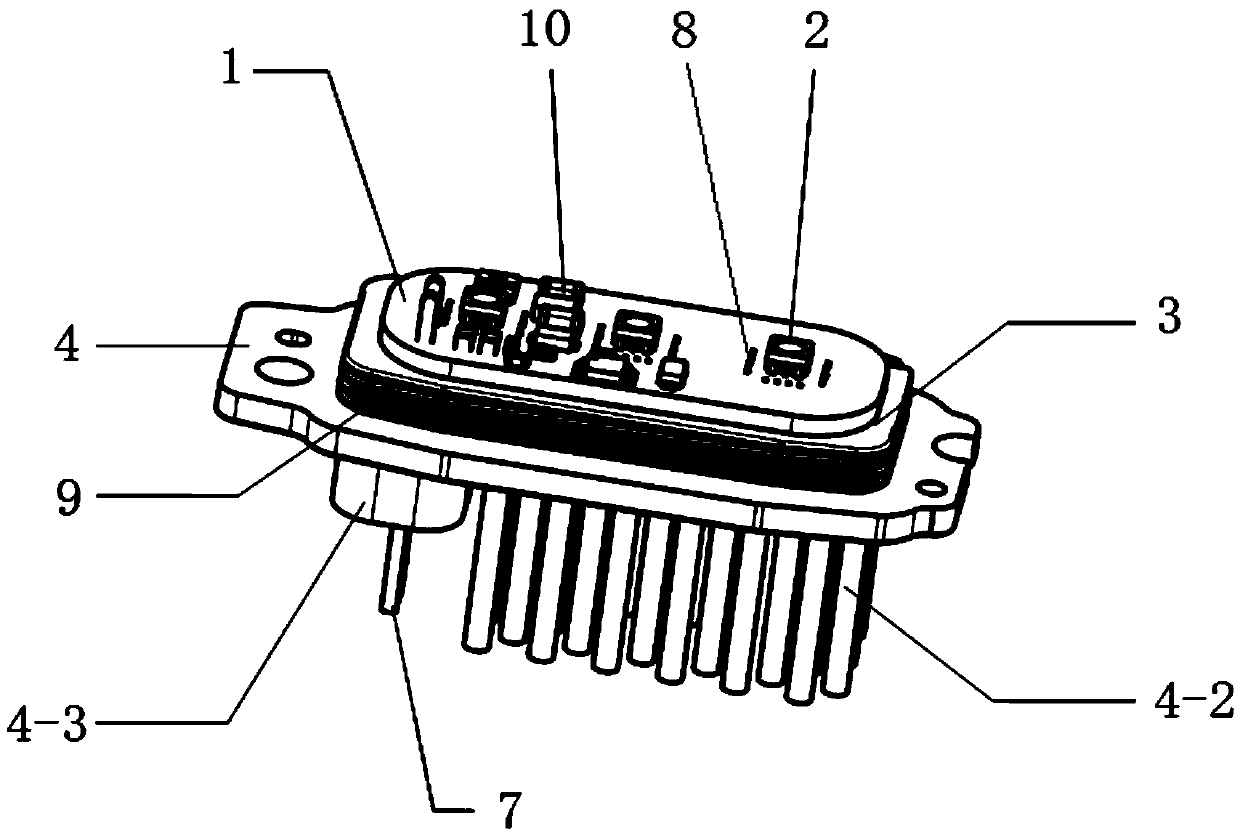

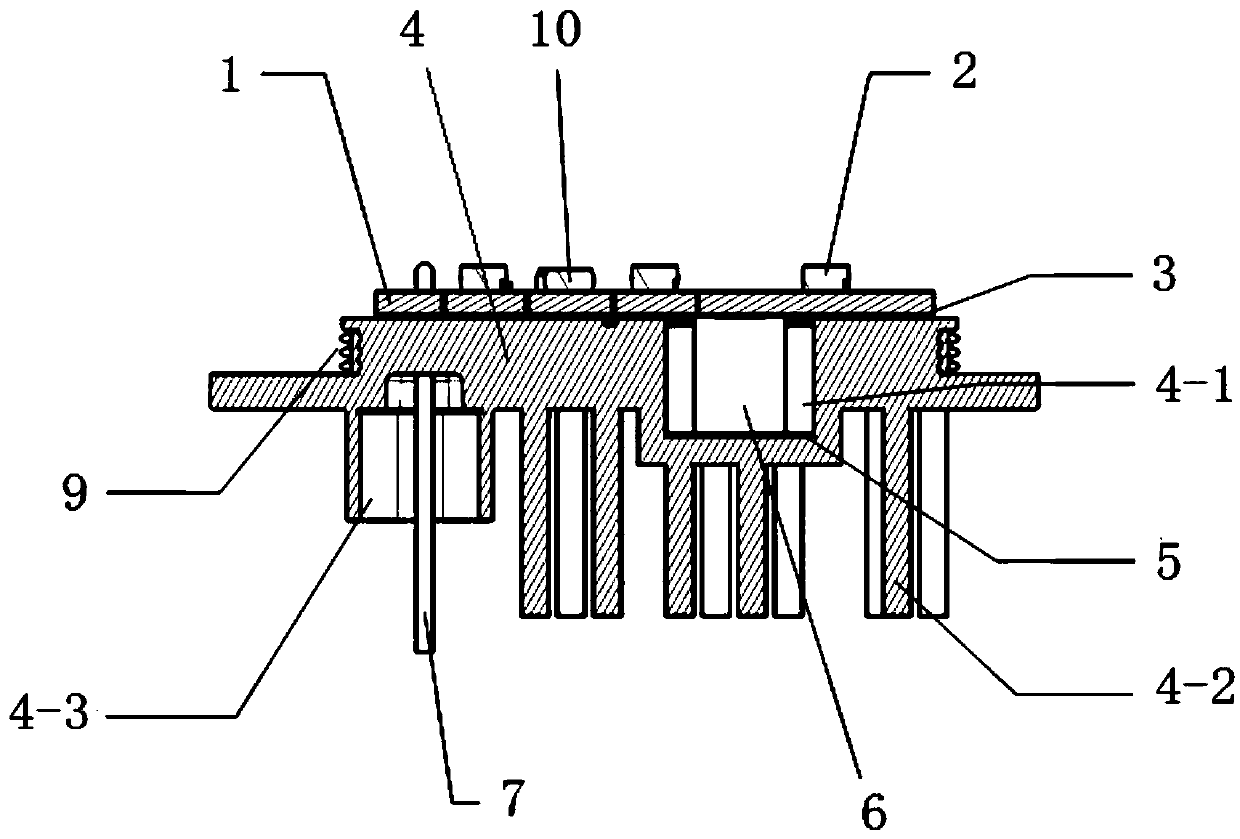

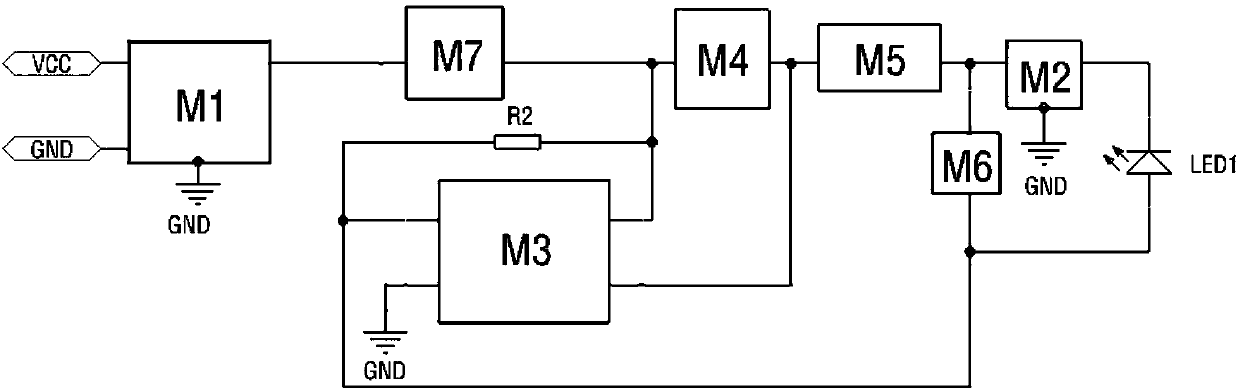

[0028] Such as figure 1 , 2 As shown, the present invention discloses an automotive signal lamp LED electronic control module, which includes an LED string and a drive circuit for the LED string (containing multiple electronic components, figure 1 Only the power device 6 and some other electronic component 10 are shown) and the same circuit board 1 on which the LED string and the driving circuit are arranged. The LED string includes one or more LEDs 2 connected in series. The circuit board is covered and fixed to the top surface of the radiator 4 through the heat dissipation adhesive layer 3, and the radiator is provided with a sink groove 4-1, which opens on the top surface of the radiator. The power device of the drive circuit is installed under the circuit board (or called the reverse side) and is located in the sink, and other electronic components of the drive circuit and the LED are all mounted on the circuit board. Top (or positive). The lower part of the heat sink is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com