Vehicle signal lamp LED electronic control module

An electronic control and signal lamp technology, applied in the field of automobile signal lamps, can solve problems such as difficult to achieve standardization, difficult to meet lamp body shape design, optical system light attenuation can not achieve the expected effect, etc., to reduce the number of electronic devices, reduce the number of devices cost, the effect of avoiding the risk of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

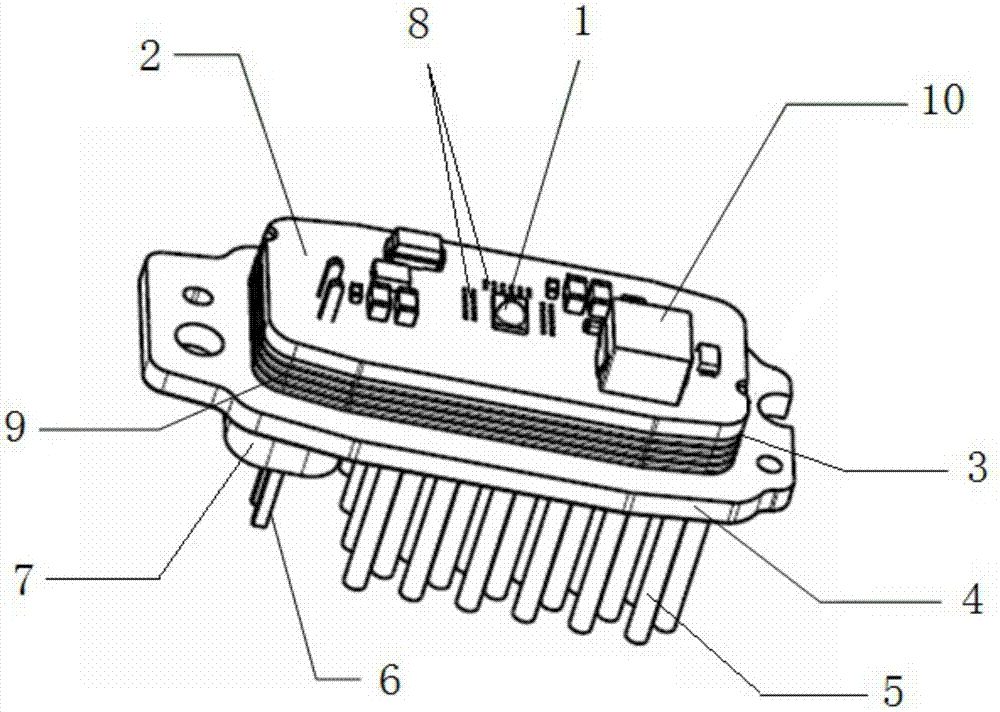

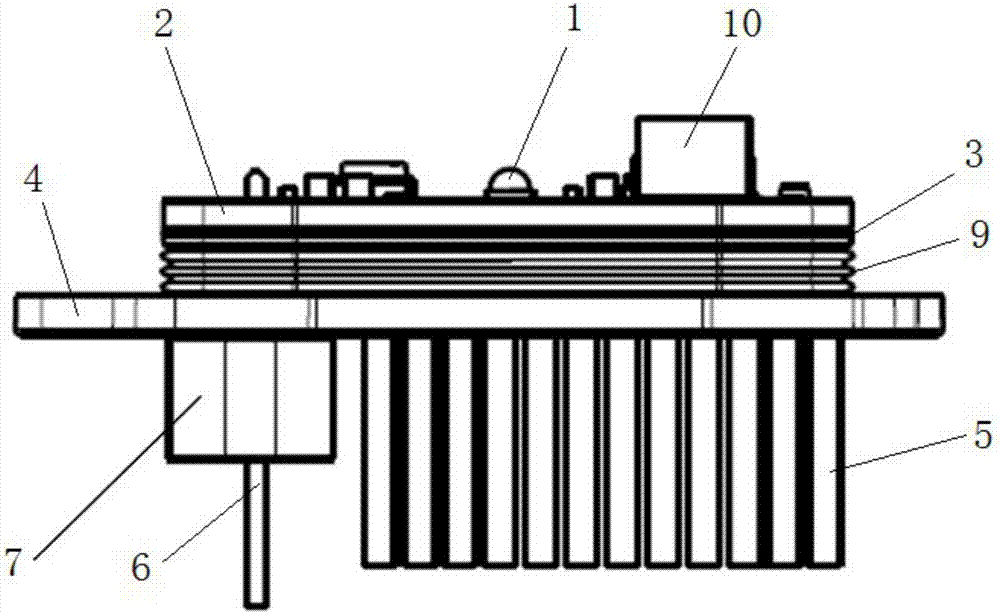

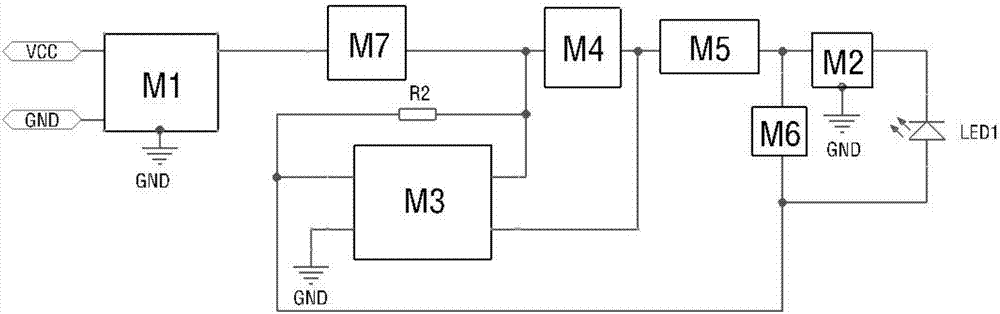

[0027] Such as figure 1 , 2 As shown, the present invention discloses a kind of LED electronic control module of automobile signal lamp, comprises LED1, LED drive circuit (contains a plurality of electronic components and parts, figure 1 One of the electronic components 10 is shown in the figure) and the same circuit board 2 on which the LED and the LED driving circuit are arranged, the electronic components of the LED driving circuit and the LED are all arranged on the front side (or top) of the circuit board. The circuit board is adhered and fixed on the base 4 of the heat sink through the heat dissipation adhesive layer 3 , and the base is provided with a sheet or column heat dissipation structure 5 and a connector inlet 7 for connecting wires or PIN pins 6 . The upper end of the connecting wire or PIN pin is welded on the circuit board, and the lower end passes through the circuit board and the connector inlet to lead out the electrical polarity, and the inside of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com