Car high beam and dipped headlight module based on laser technique

A laser technology, far and near light technology, used in electric light sources, motor vehicles, road vehicles, etc., can solve the problems of complex processing of mirrors and prisms, difficulty in precise positioning, interference with optical effects, etc. Powerful, simple cooling system, uniform light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

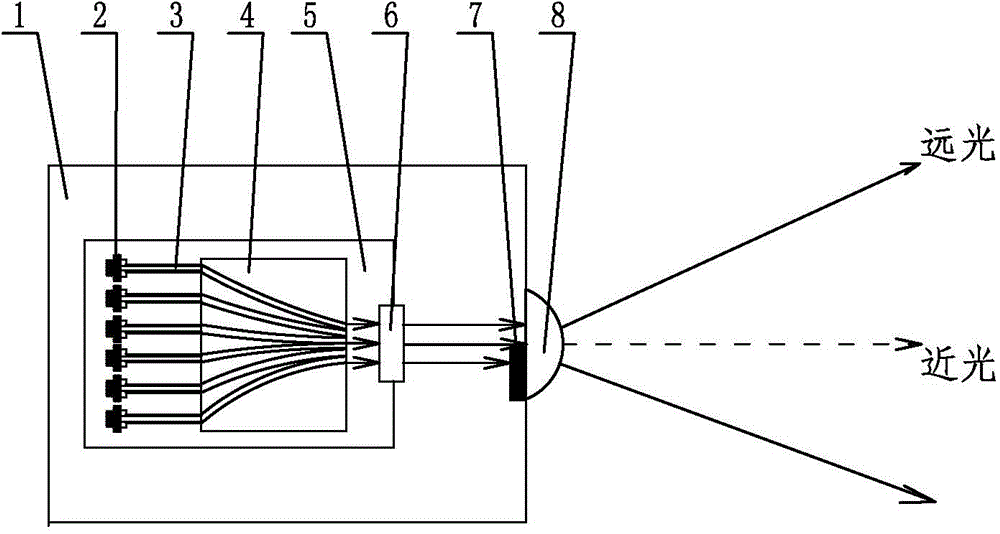

[0012] See figure 1 As shown, the automobile high and low beam lamp module based on laser technology of the present invention includes a lamp body 1 and a laser illumination light source and a PES lens 8 installed on the lamp body 1 .

[0013] See figure 1 As shown, the laser illumination light source of the present invention includes six blue laser diodes 2 with a wavelength of 450nm to form a blue laser array, the output ends of each blue laser diode 2 are docked with the input ends of the respective corresponding optical fibers 3, and the output ends of each optical fiber 3 It is docked with the input end of each corresponding optical waveguide on the quartz substrate optical waveguide chip 4, the center of each blue laser diode 2 coincides with the center of each optical fiber input end, and the input end of each optical waveguide on the quartz substrate optical waveguide chip 4 and the corresponding The centers of the fiber output ends coincide. Realize the docking of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com