Pre-splitting blasting method for joint-cutting pipe

A pre-split blasting and slitting technology, applied in the field of slitting pipe pre-split blasting, can solve the problems of large consumption of explosives and other materials, increase engineering costs, affect work efficiency, etc., to save blasting equipment and speed up project progress. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

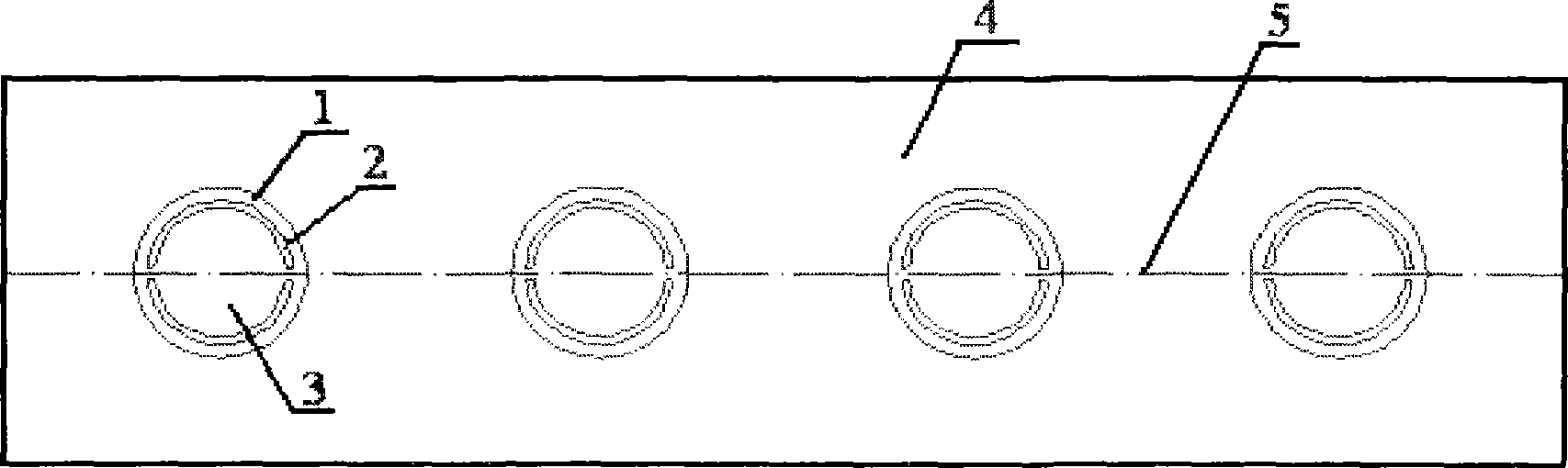

[0034] Embodiment 1 slotted pipe pre-splitting blasting method (such as figure 1 , Figure 5 shown), including the following steps:

[0035] (1) Delineate the peripheral contour line of the blasting excavation area according to the design requirements of the differential blasting, and arrange the differential blasting holes in the main blasting excavation area.

[0036] (2) Arrange pre-splitting blast holes 1 along the contour line of the blasting excavation area.

[0037] Wherein: the diameter of the pre-split blast hole 1 is 38-42 mm, and the hole spacing of the pre-split blast hole 1 is 15-40 times of the diameter of the pre-split blast hole 1 .

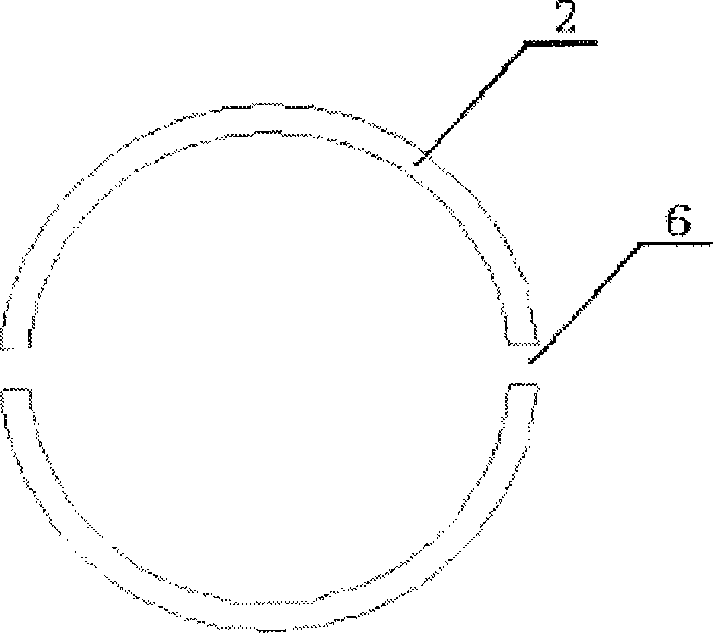

[0038] (3) Place the slit pipe 2 in the pre-split blast hole 1, so that the two slits of the slit pipe 2 are in the plane formed by the axis of the pre-split blast hole 1, that is, in the plane of the pre-split 5 to be formed .

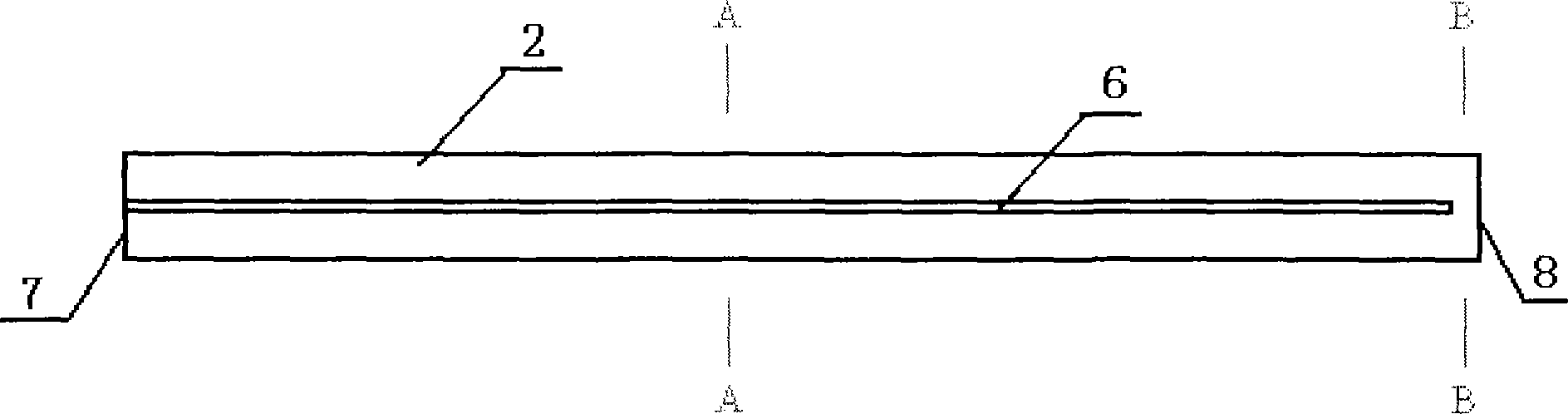

[0039] Wherein: the slit pipe 2 refers to a hollow pipe including a closed bottom end 7 and an ope...

Embodiment 2

[0046] Embodiment 2 slotted pipe pre-splitting blasting method (such as figure 1 , Figure 5 shown), including the following steps:

[0047] (1) Delineate the peripheral contour line of the blasting excavation area according to the design requirements of the differential blasting, and arrange the differential blasting holes in the main blasting excavation area.

[0048] (2) Arrange pre-splitting blast holes 1 along the contour line of the blasting excavation area.

[0049] Wherein the pre-splitting blast hole 1 is the same as that in embodiment 1.

[0050] (3) Place the slit pipe 2 in the pre-split blast hole 1, so that the two slits of the slit pipe 2 are in the plane formed by the axis of the pre-split blast hole 1, that is, in the plane of the pre-split 5 to be formed .

[0051] Wherein slit pipe 2 is with embodiment 1.

[0052] (4) According to the type of rock mass 4, the blasting charge 3 is carried out on the slit pipe 2 in the pre-splitting blast hole 1, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com