Direct welding processing method of electronic label

A technology of electronic tags and direct welding, applied in the field of RFID electronic tags, can solve the problem of high processing costs of electronic tags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structure adopts a metal antenna in the form of a copper coil and a high-frequency chip, so that the electronic label is packaged and processed by the present invention.

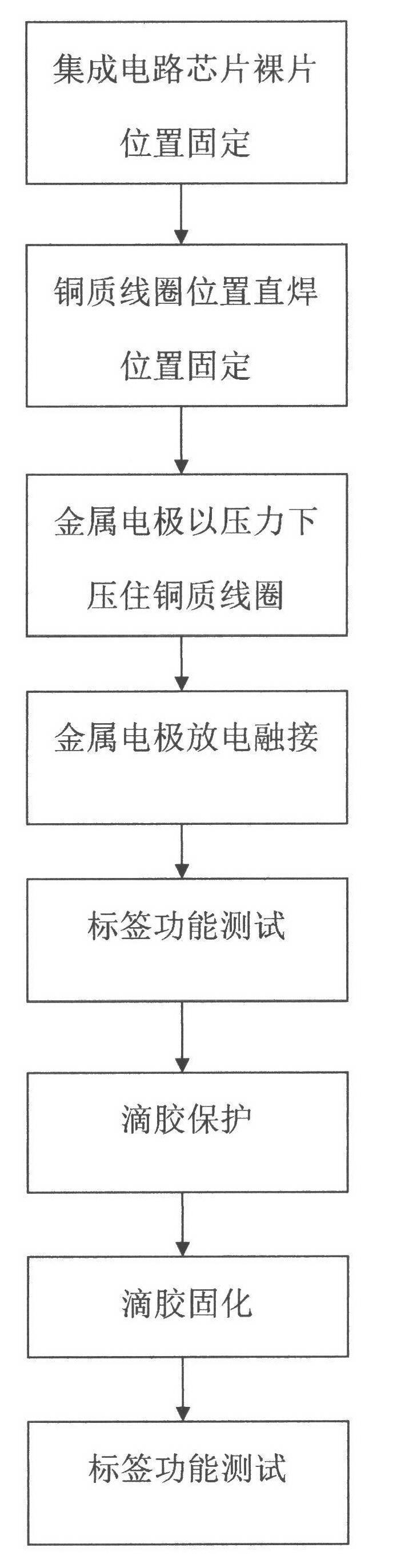

[0026] figure 1 It is a process flowchart of the present invention.

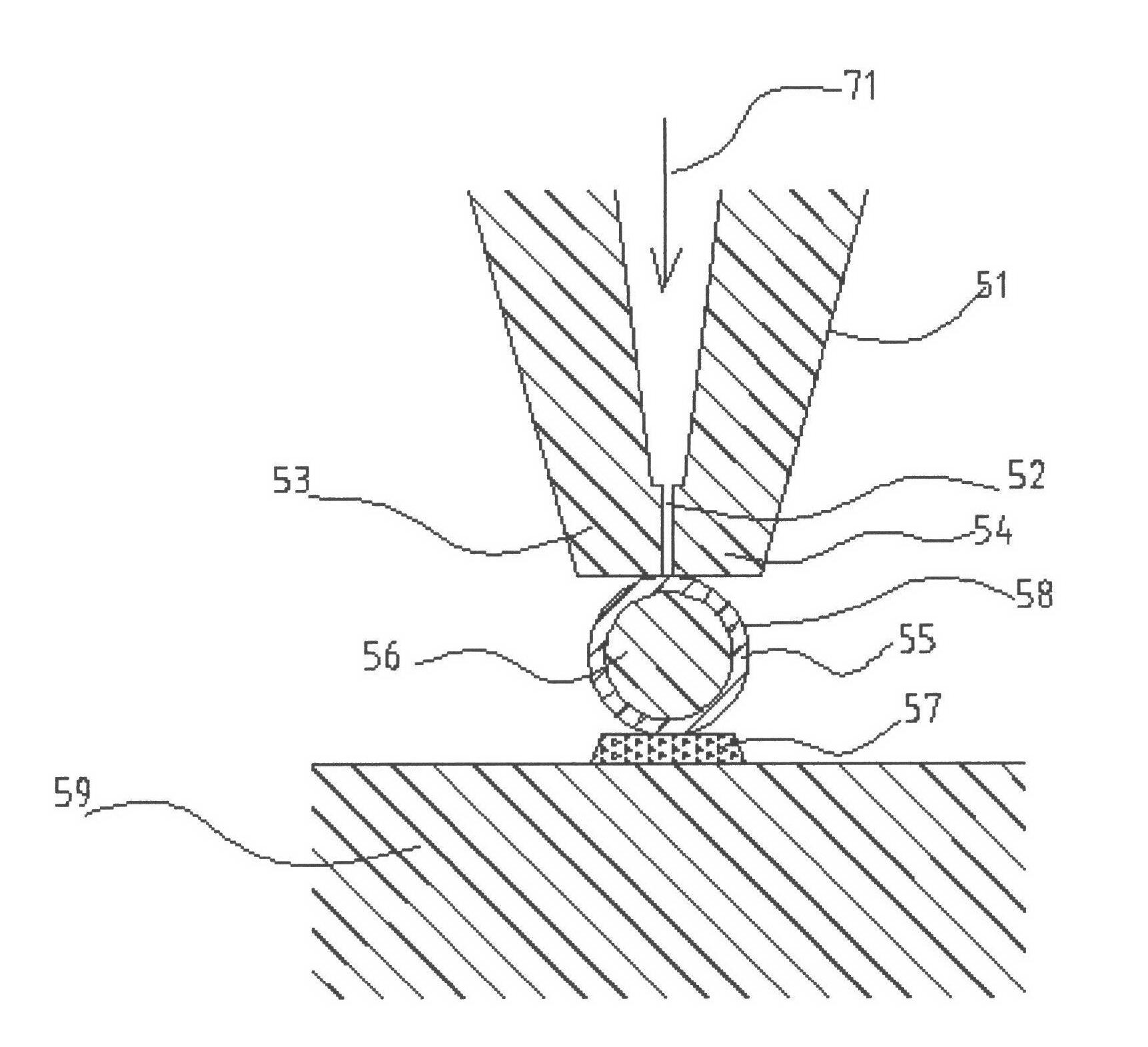

[0027] Firstly, the position of the integrated circuit chip die 59 is fixed.

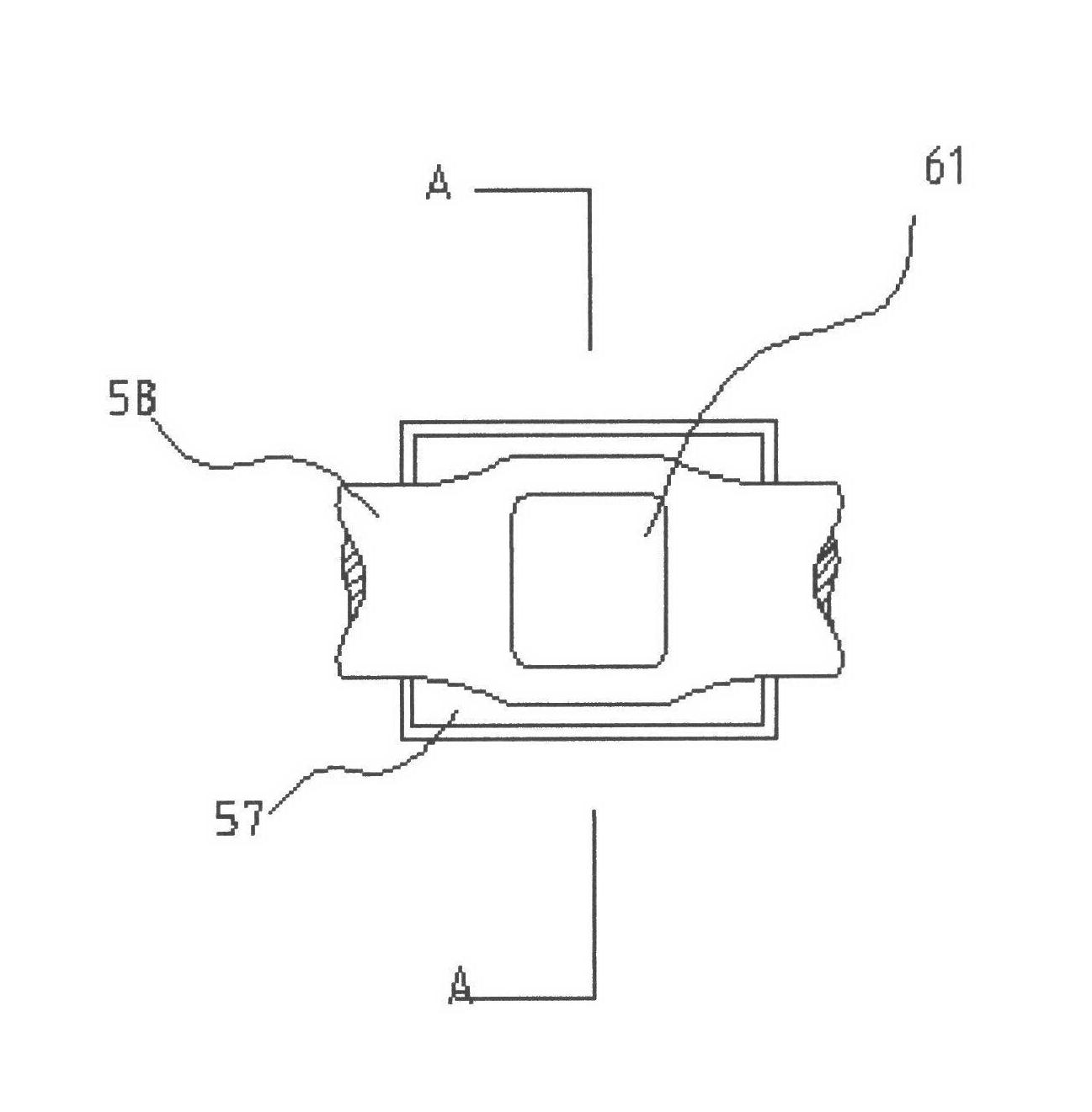

[0028] The soldering position of the metal antenna (copper coil) 58 is just placed directly above the protruding external terminal 57 on the IC chip die 59 .

[0029] The metal electrode 51 presses the welding position of the metal antenna (copper coil) 58 with a certain pressure, so that the welding position of the metal antenna (copper coil) 58 is in contact with the protruding external terminal 57 on the IC chip die 59 .

[0030] The metal electrode 51 is discharged, and the metal antenna 58 is fused with the protruding external terminal 57 on the IC chip die 59 .

[0031] Perform a label functional test to confirm successful fusion.

[0032] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com