Device for dedusting circuit board

A circuit board and electrostatic technology, applied in the field of circuit board dust removal devices, can solve the problems of workshop air pollution, dust spread, and inability to effectively remove dust, and achieve the effect of clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

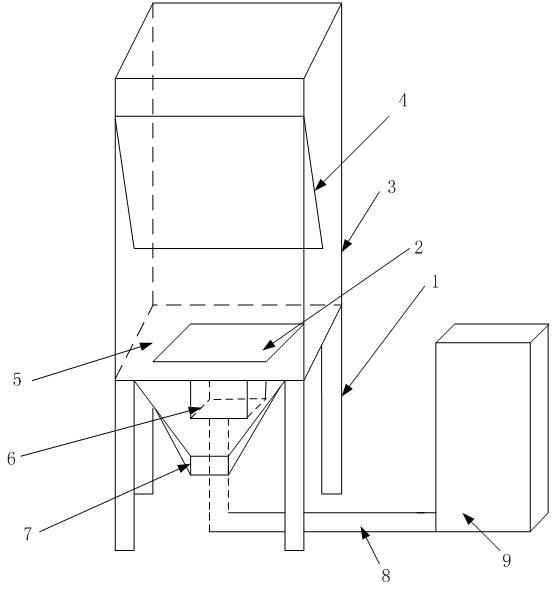

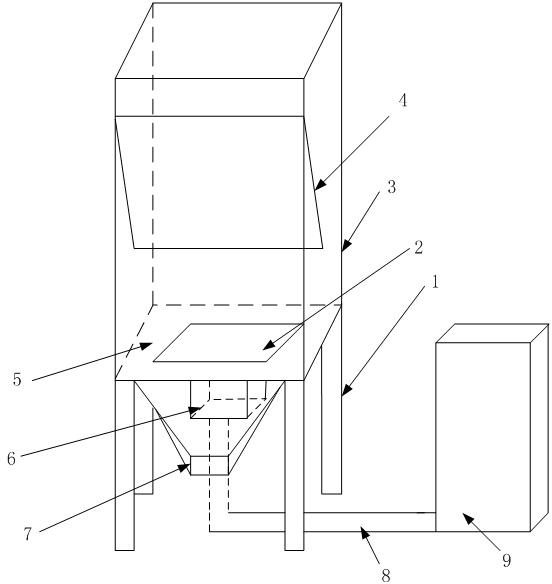

[0011] Such as figure 1 As shown, the device for removing dust from circuit boards includes a bracket 1, on which an outer frame 3 is mounted and fixed, the outer frame 3 is arranged in a semi-sealed arrangement, one side of the outer frame 3 is provided with an opening, and an electrostatic insulation skin 4 is provided at the opening , the static insulation skin 4 is fixed on the outer frame 3 and the area of the static insulation skin 4 covers the area of the opening, the circuit board bearing panel 5 is installed on the bottom of the inner cavity of the outer frame 3, and the exhaust fan device 6 is fixed on the bottom of the outer frame 3 , the exhaust fan device 6 is matched with the circuit board bearing panel 5 , and the exhaust fan device 6 is connected with the dust collection device 9 through the dust adsorption pipe 8 .

[0012] The opening of the outer frame 3 is provided with a circuit board collection funnel 7, and the circuit board collection funnel 7 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com