Coordinate computing method for continuous bending roller rows and straightening section roller rows of slab casting machine

A slab continuous casting machine, coordinate calculation technology, applied in the field of roll column design of slab continuous casting machine, can solve problems such as few reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

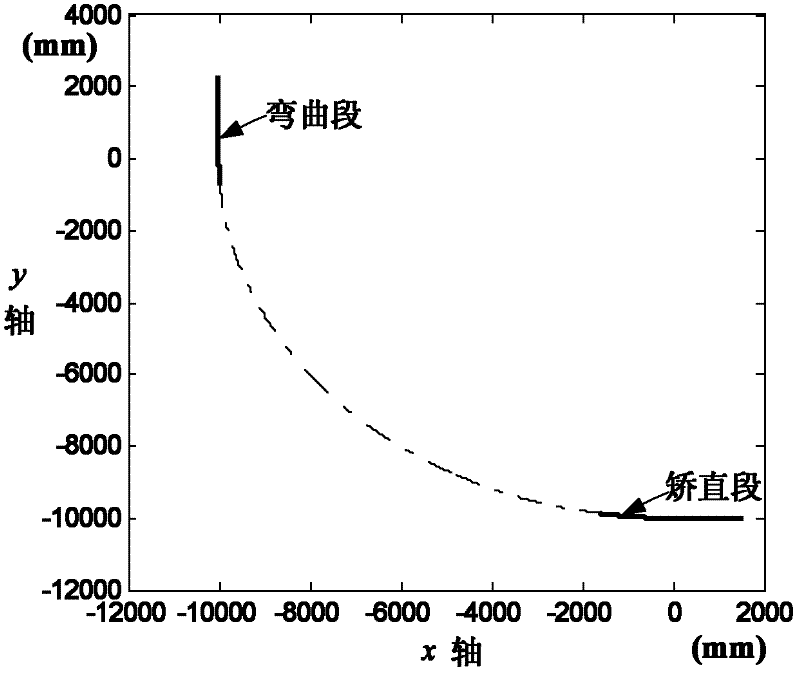

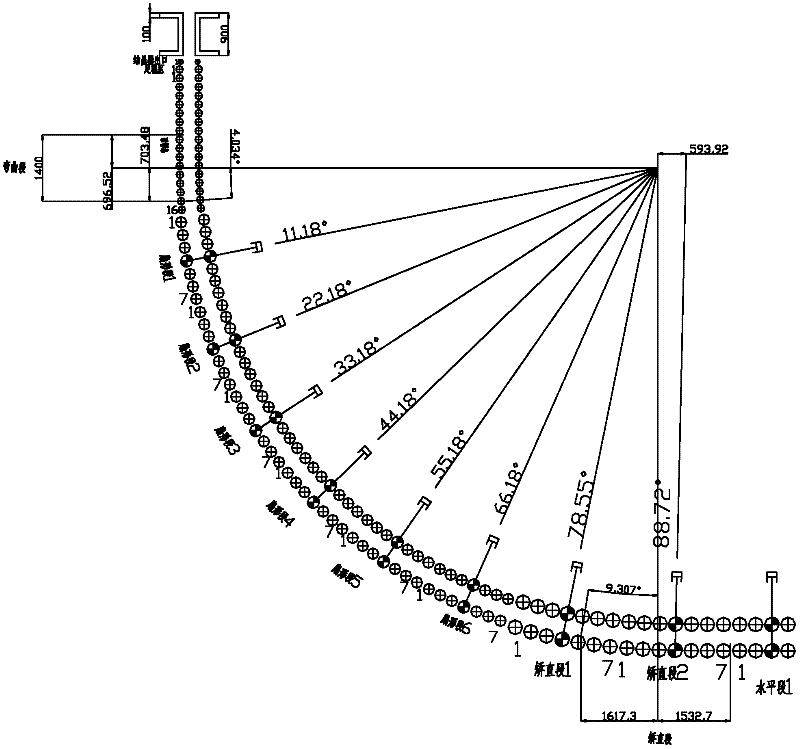

[0070] The parameters of the bending section and the straightening section of a slab continuous casting machine in a steel plant are the slab thickness D = 250mm, the slab width B = 2300mm, and the basic arc radius R 0 =10000mm, the length of the bending zone L b =1400mm, the length of straightening zone L s = 3150mm.

[0071] Then the continuous casting machine bending zone coefficient K b = 1.00747, bending zone angle α b =4.03399°, the total arc length S of the bending zone b =1400.7mm; Straightening zone coefficient K s =1.04056, straightening zone angle α s =9.30735°, total arc length S in straightening zone s = 3158.43 mm.

[0072] The coordinates of the starting point of the bending zone are (-10008.14, 696.52), the coordinates of the end point of the bending zone are (-9975.22, -703.48), the coordinates of the starting point of the straightening zone are (1532.7, -10040.43), and the coordinates of the end point of the straightening zone are (-1617.30, -9868.35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com