Tool machine, especially handheld tool machine

A technology of hand-held machine tools and machine tools, which is applied in the direction of manufacturing tools, portable mobile devices, metal processing equipment, etc., and can solve problems such as increasing frictional resistance and affecting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

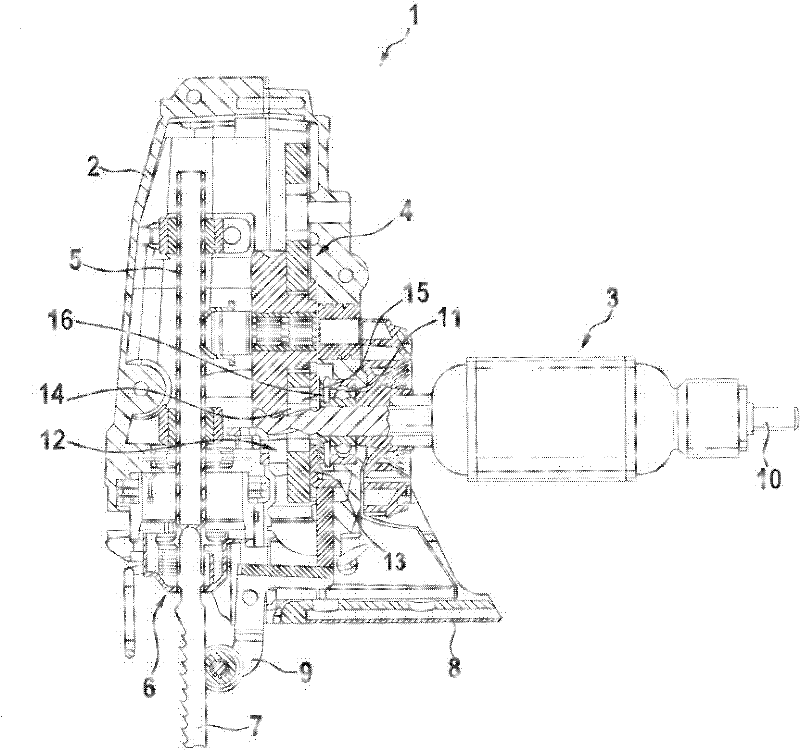

[0020] Such as figure 1 As shown, the jigsaw 1 has a housing 2 in which are arranged an electric drive motor 3 and a transmission 4 for driving a reciprocating rod 5 on which a saw blade 7 is fastened via a fastening device 6 . On the underside of the housing 2 there is a base plate 8 which bears on the upper side of the workpiece during its machining. The saw blade 7 is arranged in front of the base plate 8 , wherein if necessary a recess can also be provided in the base plate 8 through which the saw blade 7 passes. The saw blade 7 is supported on the rear by a housing-side support device 9 .

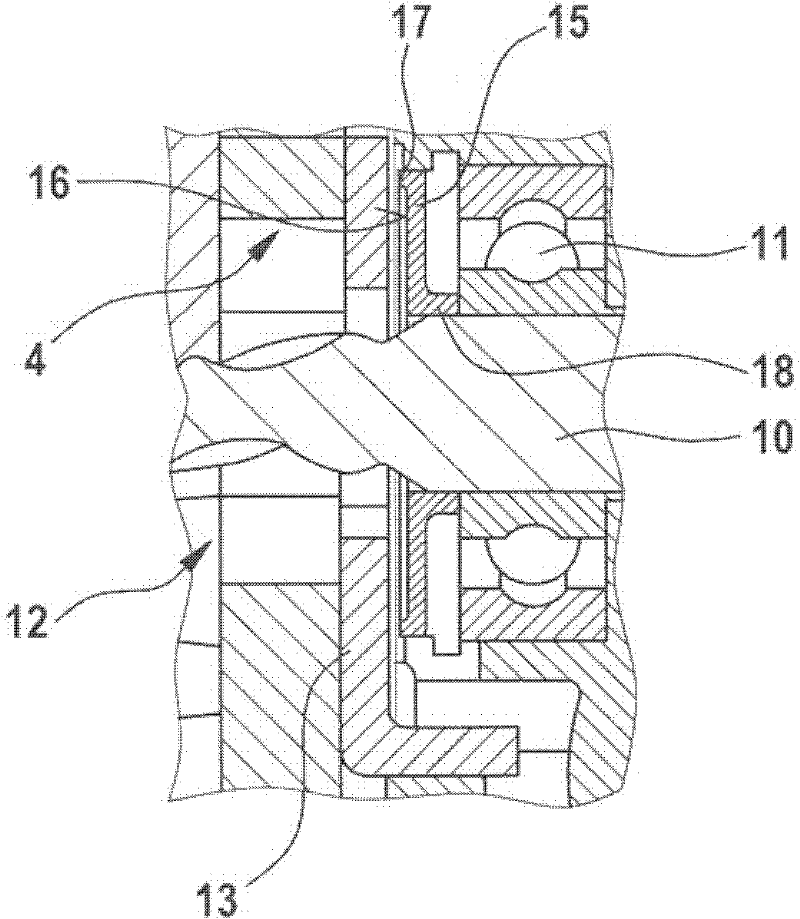

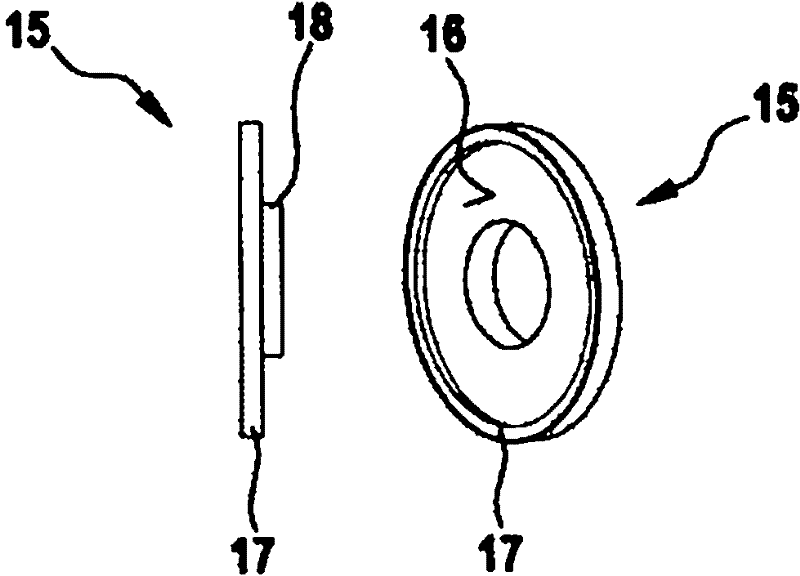

[0021] The electric drive motor 3 has a rotor shaft or armature shaft 10 , the longitudinal axis of which is oriented orthogonally to the longitudinal axis of the reciprocating rod 5 . A section of the rotor shaft 10 protruding beyond the stator of the drive motor 3 is mounted rotatably in a ball bearing 11 in the housing, the ball bearing 11 being designed as a deep groove ball bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com