Synchronous compacting mechanism for shell machining

A technology of pressing mechanism and housing, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of high processing cost, uneven pressing force, large space occupied, etc. Improves stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

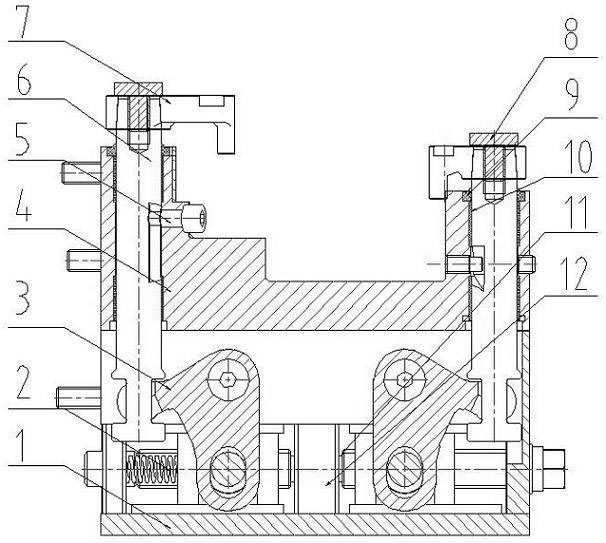

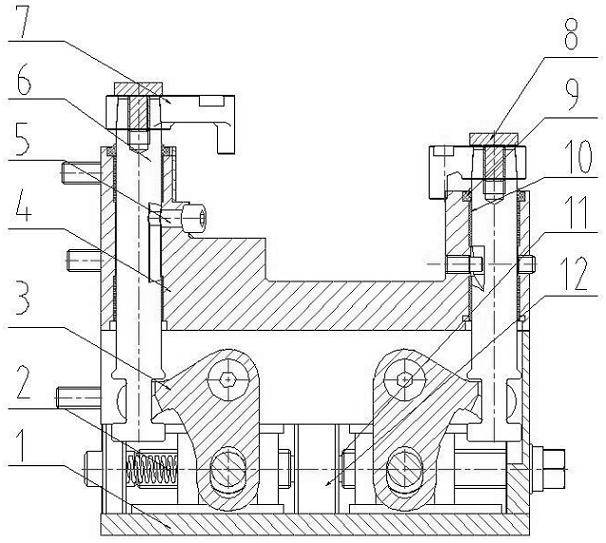

[0008] Such as figure 1 As shown, a synchronous pressing mechanism for shell processing includes a base (1), a piston rod (2), a shift fork (3), a support seat (4), a stop screw (5), a floating rod (6), Pressing plate (7), screw (8), dust-proof ring (9), oil-free bearing (10), slider (11), movable rod (12), movable rod (12) is fixed on the base (1) by thread , the shift fork (3) is installed on the piston rod (2), the fixed pressure plate (7) is fixed on the floating rod (6) by the screw (8), the oil-free bearing (10) and the dust-proof ring (9) are installed on the support inside the seat (4).

[0009] Specific working principle: The present invention is a synchronous pressing mechanism for shell processing, which adopts manual pressing. The base (1) is equipped with a movable rod (12) and a nut, and the nut is fixed on the movable rod (12). With the rotation of the movable rod (12), the nut moves back and forth, driving the expansion and contraction of the piston rod (2), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com